How cold plasma functionalizes 3D-printed PCL scaffolds for tissue engineering.

How cold plasma functionalizes 3D-printed PCL scaffolds for tissue engineering.

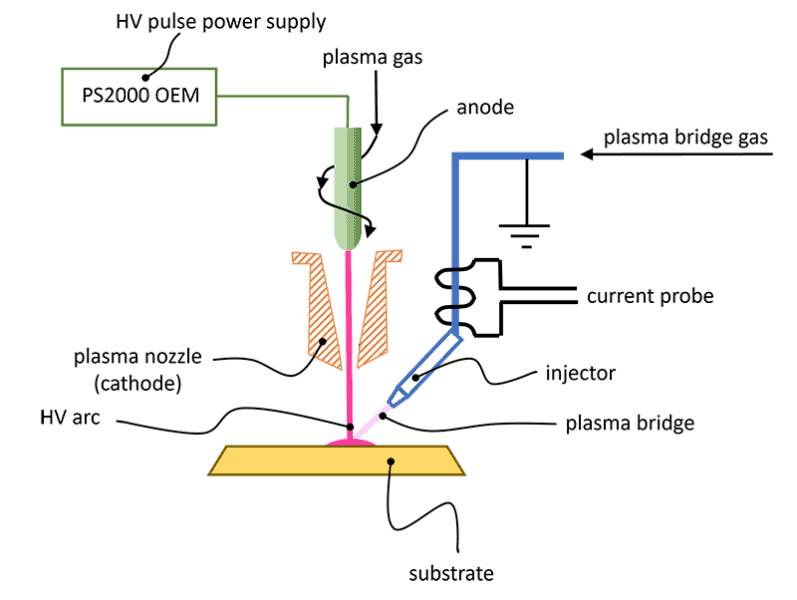

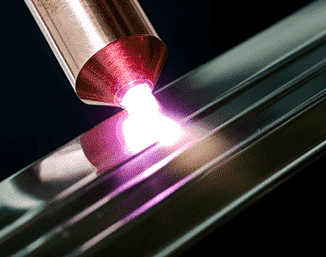

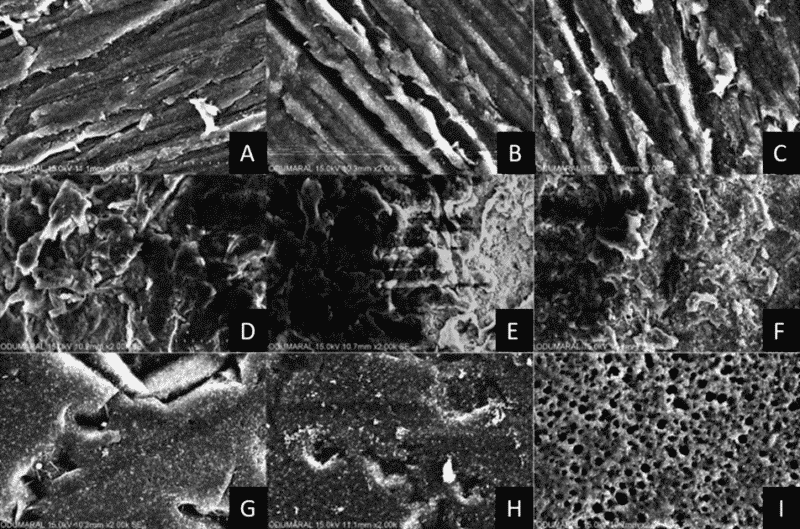

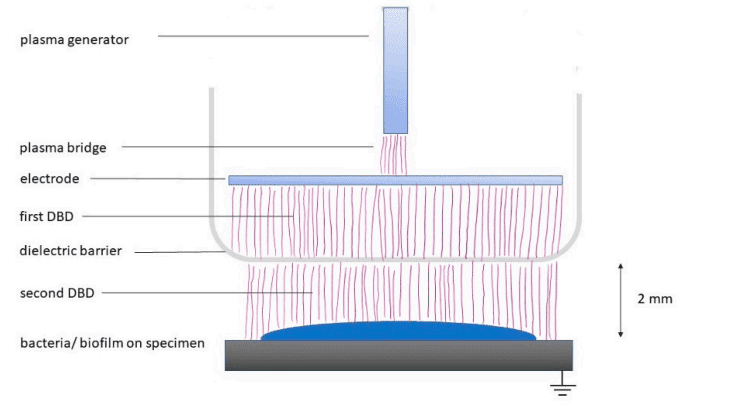

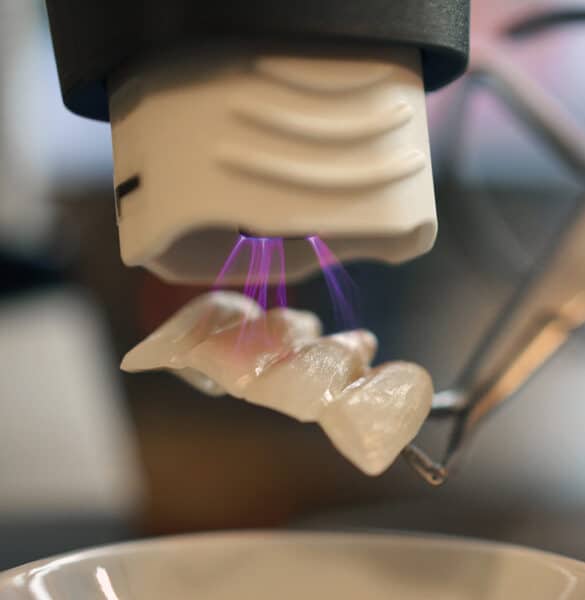

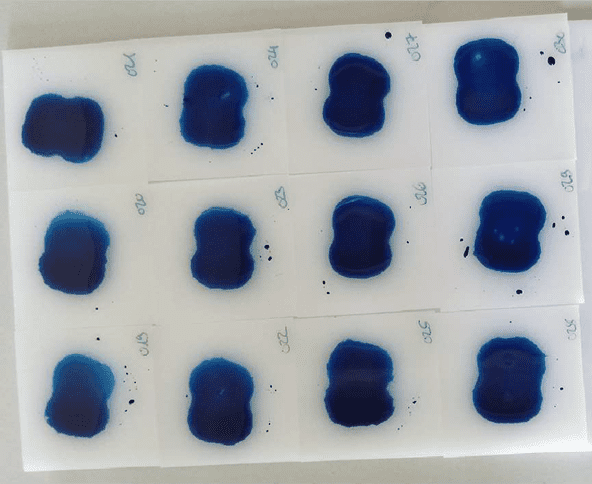

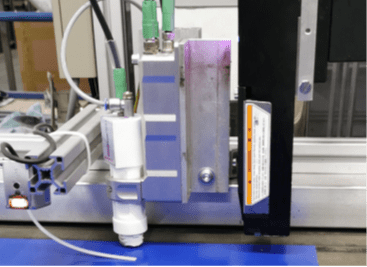

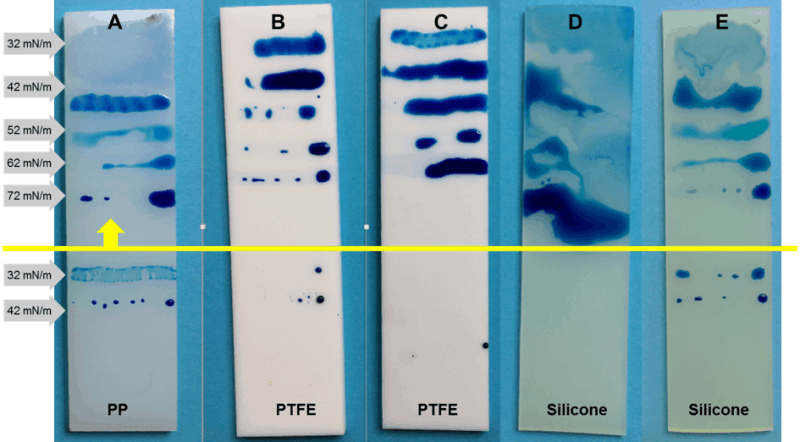

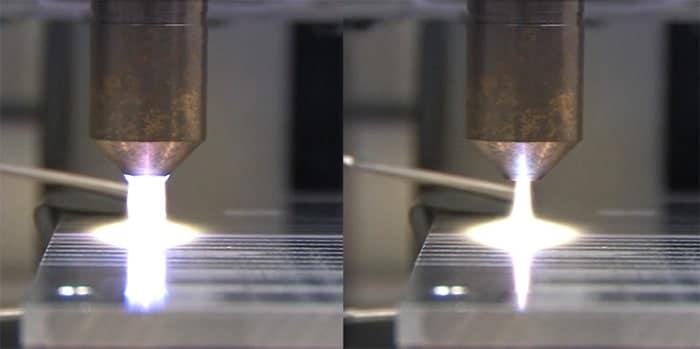

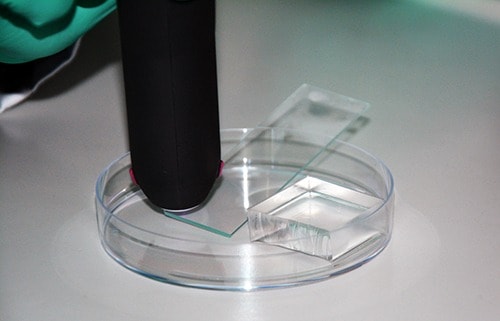

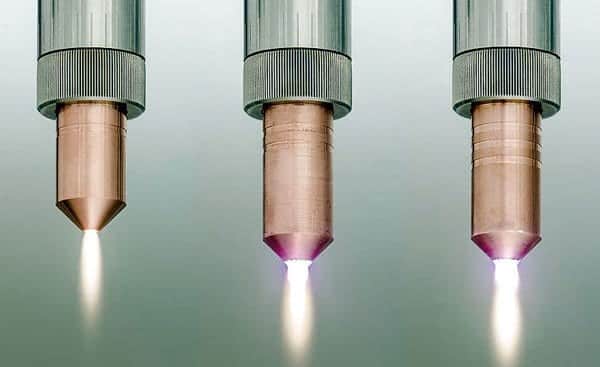

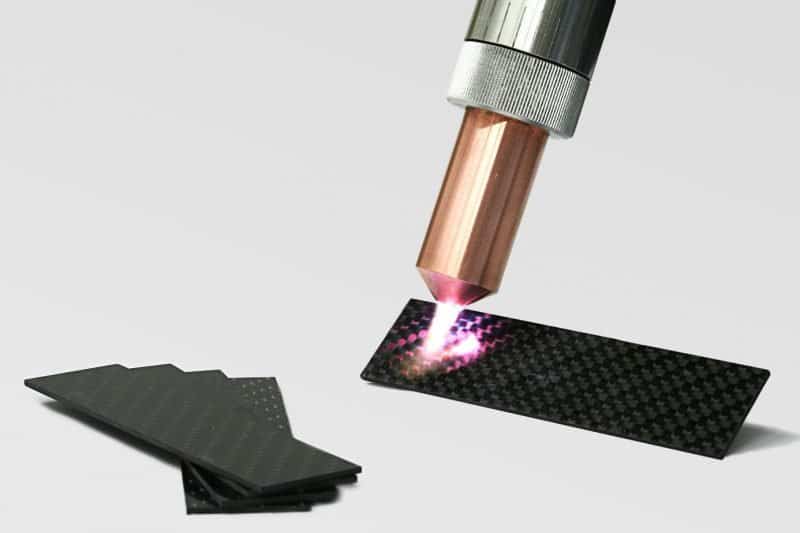

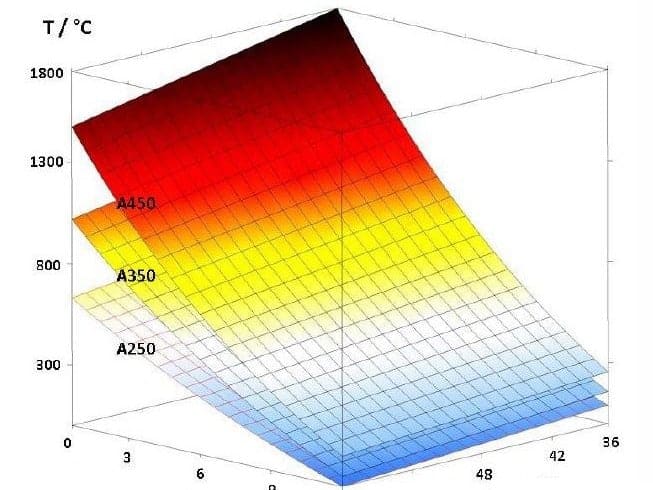

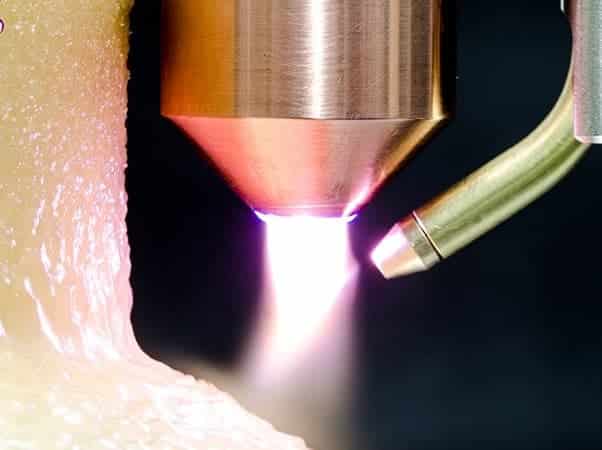

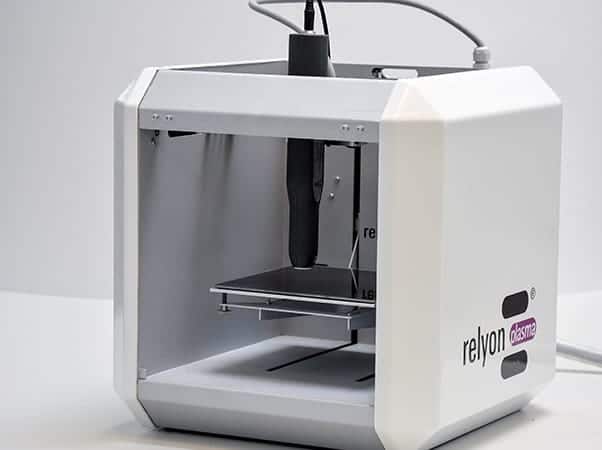

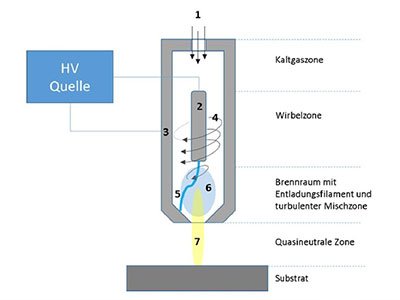

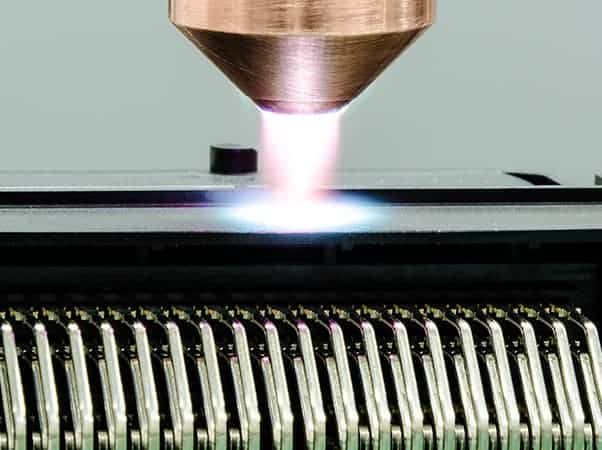

The combination of additive manufacturing and plasma technology opens up new avenues in regenerative medicine and tissue engineering. A particularly innovative approach is the cold plasma surface modification of 3D-printed polycaprolactone (PCL) scaffolds, as is currently being researched at the Cabral Laboratory of the University of Otago (New Zealand).