Influence of non-thermal plasma systems and two favorable surface treatments

on the shear bond strength of PAEKs to composite resin

Authors: Dede, D. Ö., Ercan, U. K., Küçükekenci, A. S., Kahveci, Ç., Özdemir, G. D. & Bağış, B.

Publication: Influence of non-thermal plasma systems and two favorable surface treatments on the shear bond strength of PAEKs to composite resin, Journal of Adhesion Science and Technology, 2022, 36 (7), 748-761.

First published: https://www.tandfonline.com/doi/full/10.1080/01694243.2021.1936784

Summary:

The polymers polyetheretherketone (PEEK) and polyetherketoneketone (PEKK) are part of the polyaryletherketones (PAEK). They are of great interest for (dental) implants due to their biocompatibility and bone-like mechanical properties. However, the physical and chemical inertness of the substances also poses challenges in their processing.

The aim of this study therefore was to investigate the influences of non-thermal plasma (NTP) on the shear bond strength and surface roughness of PEEK and PEKK in composite resin. For this purpose, the polymers were partially pretreated by sandblasting or by etching using sulfuric acid.

In the study the NTP was generated based on two technologies: dielectric barrier discharge (DBD) and piezoelectric direct discharge (PDD). The piezobrush® PZ2 was used to generate PDD plasma.

The pre-treatment of a total of almost 300 PEEK and PEKK substrates (7 mm x 7 mm x 3 mm) were each divided into 9 different groups. These included a control group, pre-treatment of the substrates only by plasma (DBD and PDD), by sandblasting with silica-coated aluminium oxide particles and etching by highly concentrated sulphuric acid. Likewise, sandblasting and etching were each combined with one of the two methods for generating NTP (DBD and PDD).

The highest shear bond strength for PEEK was achieved on the substrates etched with sulphuric acid with a value of 20.29 ± 2.31 MPa (control group value: 8.54 ± 0.81 MPa). For PEKK, sandblasting was the most effective method. It increased the shear bond strength to 18.91 ± 1.09 MPa (control group value 8.68 ± 0.61). Treatment with the piezobrush® PZ2 resulted in an increase to 11.37 ± 0.53 MPa (PEEK) and 11.28 ± 1.11 MPa (PEKK). The plasma generated by DBD did not provide a significant increase. Furthermore, the combinations of sandblasting with plasma and etching with plasma also increased the shear bond strength values.

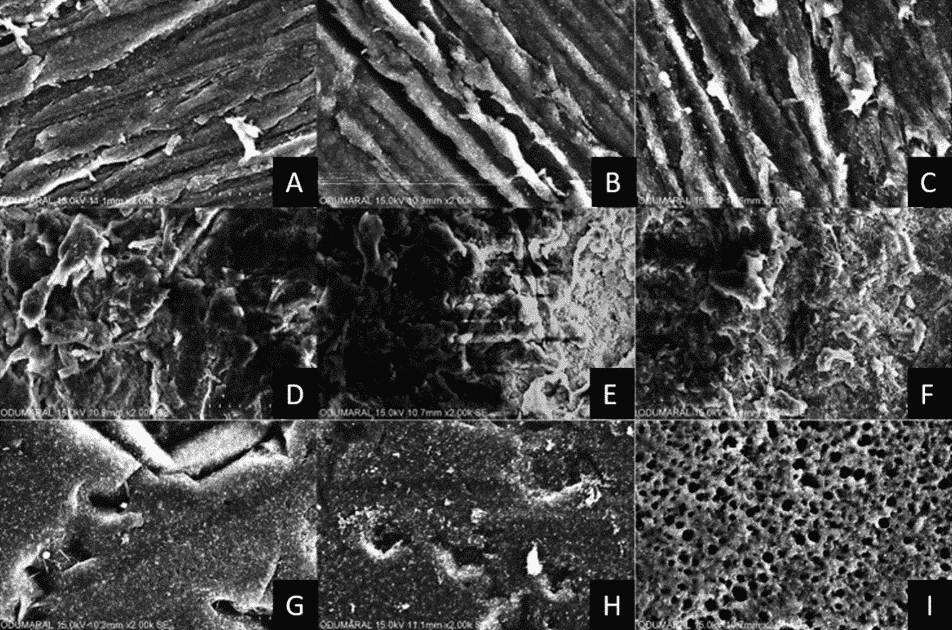

The surface roughness of PEEK and PEKK increased for both polymers only with sandblasting. They did not increase when treated with PDD and DBD. After etching, the surface roughness were even lower. It is striking that plasma treatment alone did not change the basic structure of the polymers, whereas sandblasting had a strong roughening effect. Etching tended to reverse these irregularities, with small cavities appearing after subsequent PDD treatment (cf. SEM images in Fig. 2, bottom right).

With the already established methods of sandblasting and etching, good results can be achieved for increasing shear bond strength. However, their invasive and toxic properties are often critical for applications in the clinical field . Here plasma can provide a remedy. In this study, treatment with the piezobrush® PZ2 led to a significant increase in shear bond strength. Consumables can be dispensed with in the process.

Conclusion:

The study has shown that surface treatment of PAEKs with relyon plasma’s piezobrush® PZ2 prior to bonding to composite resin enables an increase in shear bond strength. Although already established methods achieve good results, activation by a compact hand-held device without the use of toxic consumables is quite promising.