Typical plasma applications

Fields of application

Surface treatment with plasma is used in numerous industries and typical branches worldwide:

- Automotive industry

- Digital printing

- 3D printing

- Semiconductor technology

- Shipbuilding and aircraft construction

- Medicine and Cosmetics

- Packaging technology

- Electronics

- Dentistry

- Textile industry

- just to give a few examples.

Plasma technology as such is still a quite new technology and yet more and more conventional pre-treatment processes in industry are being replaced by plasma technology. This is mainly due to the fact that manufacturing processes can be made more effective and environmentally friendly through the use of plasma, since many chemically complex and environmentally damaging processes can be dispensed with.

We have successfully integrated our plasma products in the following plasma applications:

- Cleaning of metals, glass and plastics

- Surface activation and functionalization to increase wettability

- Coating for new surface properties

- Plasma supported lamination processes

- Plasma supported adhesive bonds

- Sealing

- Plasma induced reduction of metal surfaces

- Bleaching of textiles without the use of chemicals

- Plasma sterilization of fabrics

- Food treatment for quality and increased shelf life

- Sterilization and disinfection of thermally sensitive plastic materials

- Multicomponent injection molding

-

Varnishing -

Print pre-treatment -

Sterilization and disinfection -

Adhesive preparations -

Superfine cleaning

Treatable materials and geometries

Atmospheric pressure plasmas can treat a wide range of materials, including but not limited to:

- Metals, metal alloys

- Plastics and composite materials

- Glass, ceramics, inorganic composite materials, natural stone

- Natural leather, imitation leather

- Natural fiber, wood, paper

Advantages of the plasma processing

Plasma cleans, strengthens and chemically functionalizes the surface. All these effects, which are required for improved adhesive bonding, are achieved simultaneously in a single step. Most importantly, the plasma processing works at atmospheric pressure. Its advantages comparing to standard chemical and vacuum plasma cleaning processes include:

- Ultra-fine cleaning, no residues

- Gentle, non-destructive surface treatment

- No wet chemistry

- Air or cheap non-toxic working gases

- Environmental friendliness

- No expensive vacuum equipment

- Fast processing speeds

- Easy integration into existing production lines

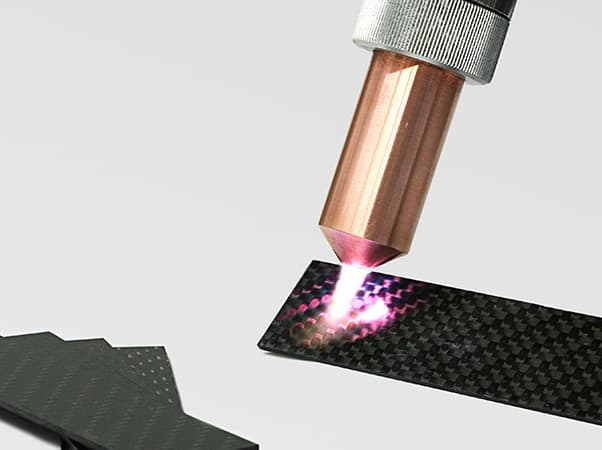

Mode of action of atmospheric pressure plasma

Atmospheric pressure plasmas, produced by electric discharges in air or other working gases, possess a unique combination of properties such as being chemically active, cold, and at the same time environmentally friendly, safe and cheap. Such plasmas produce large quantities of very reactive, but short-lived chemical species. These species can disinfect, clean, modify and functionalize a broad range of surfaces, preparing them for adhesive bonding, varnishing and printing. Plasma pre-treatment dramatically improves the quality of the results.

While being very effective, the plasma is cold; it does not overheat the surface. The treatment extends only to a nm-width thin surface layer and it does not affect the surface visually. Moreover, the process does not use toxic chemicals, and the reactive chemical species, produced within the plasma, decay within milliseconds after the treatment. This makes the plasma treatment is safe and environmentally friendly.

Atmospheric plasma equipment is significantly cheaper comparing to the low-pressure plasmas, as it does not require expensive vacuum chambers and pumps. Furthermore, in most cases it uses air as the working gas, cutting the need for expensive gases. At the same time, it is very versatile – it can be integrated into both, the batch and the running conveyor production lines. Thus, plasma increases production throughputs, while saving on chemical consumables, safety equipment and training.

What can be treated?

Our atmospheric plasma generator

- One-dimensional products such as filaments, threads and fibers can be treated at high speeds in-line.

- Two-dimensional products such as membranes, textile fabrics, foils and plastic sheets can be treated at high speeds in roll-to-roll processing.

- Cylindrical products such as tubes, pipes and cables can be treated. We offer solutions to treat also inner parts of pipes and even thin capillaries.

- Complex structures can be treated using robotized systems such as our Plasmacell 300 or specialized solutions that can be programmed to follow complex contours in three dimensions.

- Granulates and powders can be treated by injecting them into the plasma jet of our PlasmaBrush PB3.