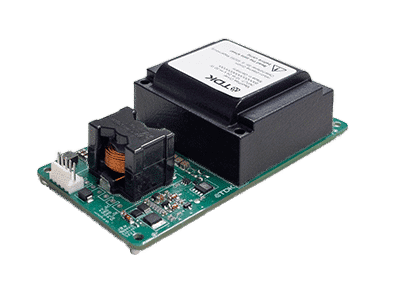

MediPlas Driver

Driver for RONS generators as a component for industrial and medical applications

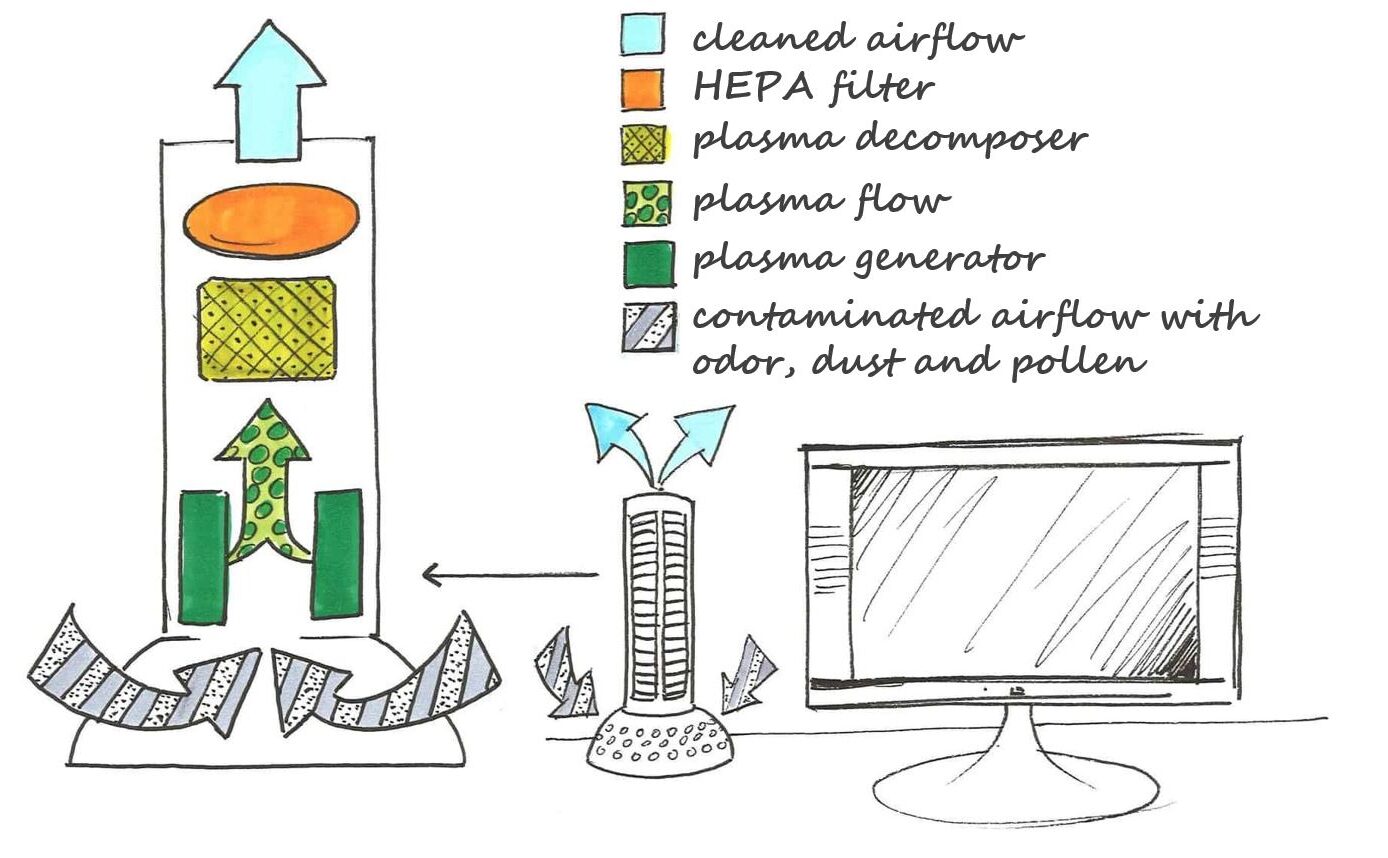

The MediPlas Driver is a driver for RONS (reactive oxygen and nitrogen species) generators. The high voltage source provides the necessary voltage power for RONS generation. The MediPlas Driver and the MediPlas Reactor from TDK can be integrated into applications as components for cleaning and disinfecting.

The high voltage source is designed to operate with a suitable plasma generator. The ozone generator driver converts a DC low voltage to AC high voltage using an autoresonant circuit topology. The output frequency independently adjusts to the load being operated.

We are looking for partners who would like to benefit from the advantages of our DBD components and integrate our modules into their systems.

We are looking for partners >>

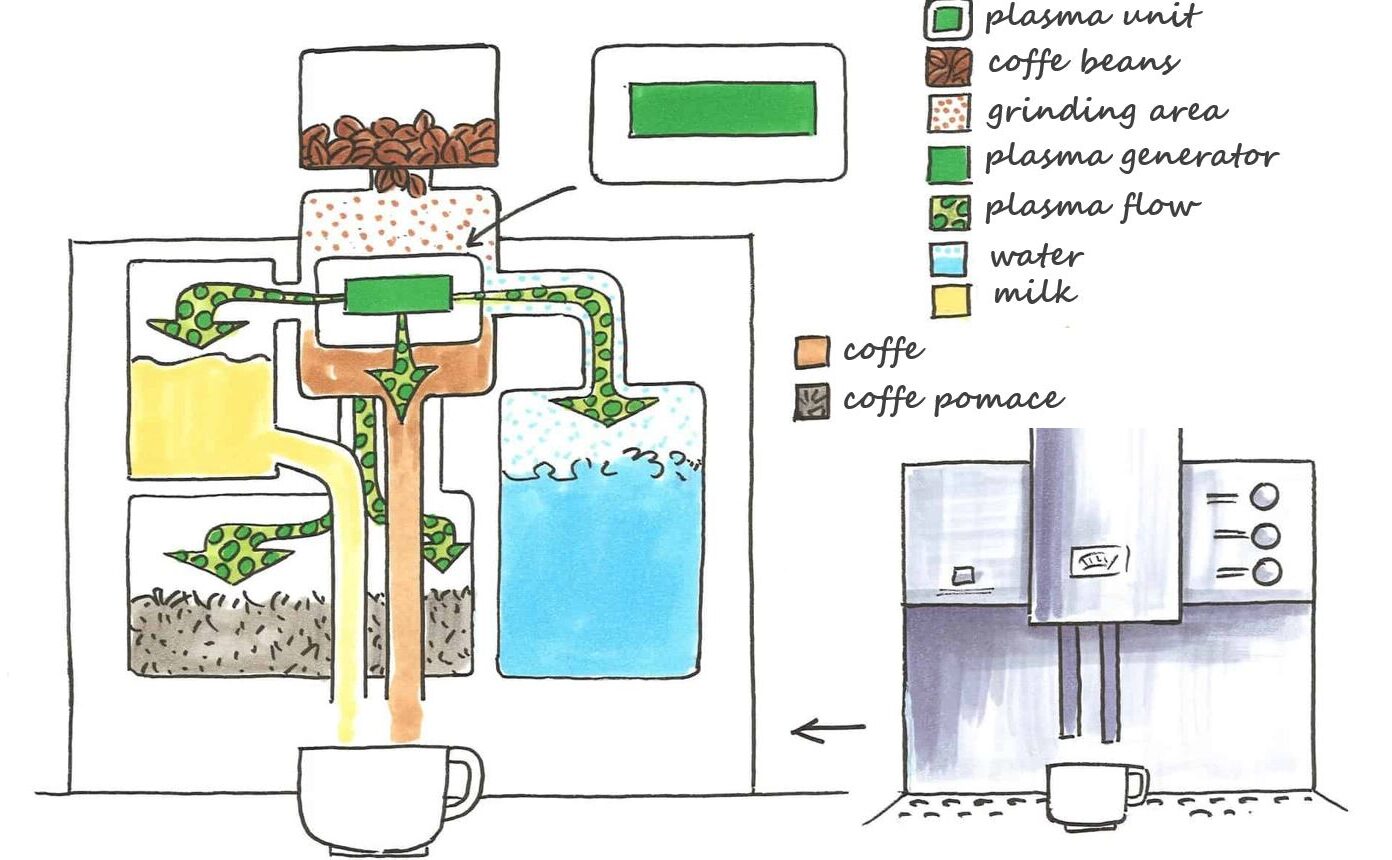

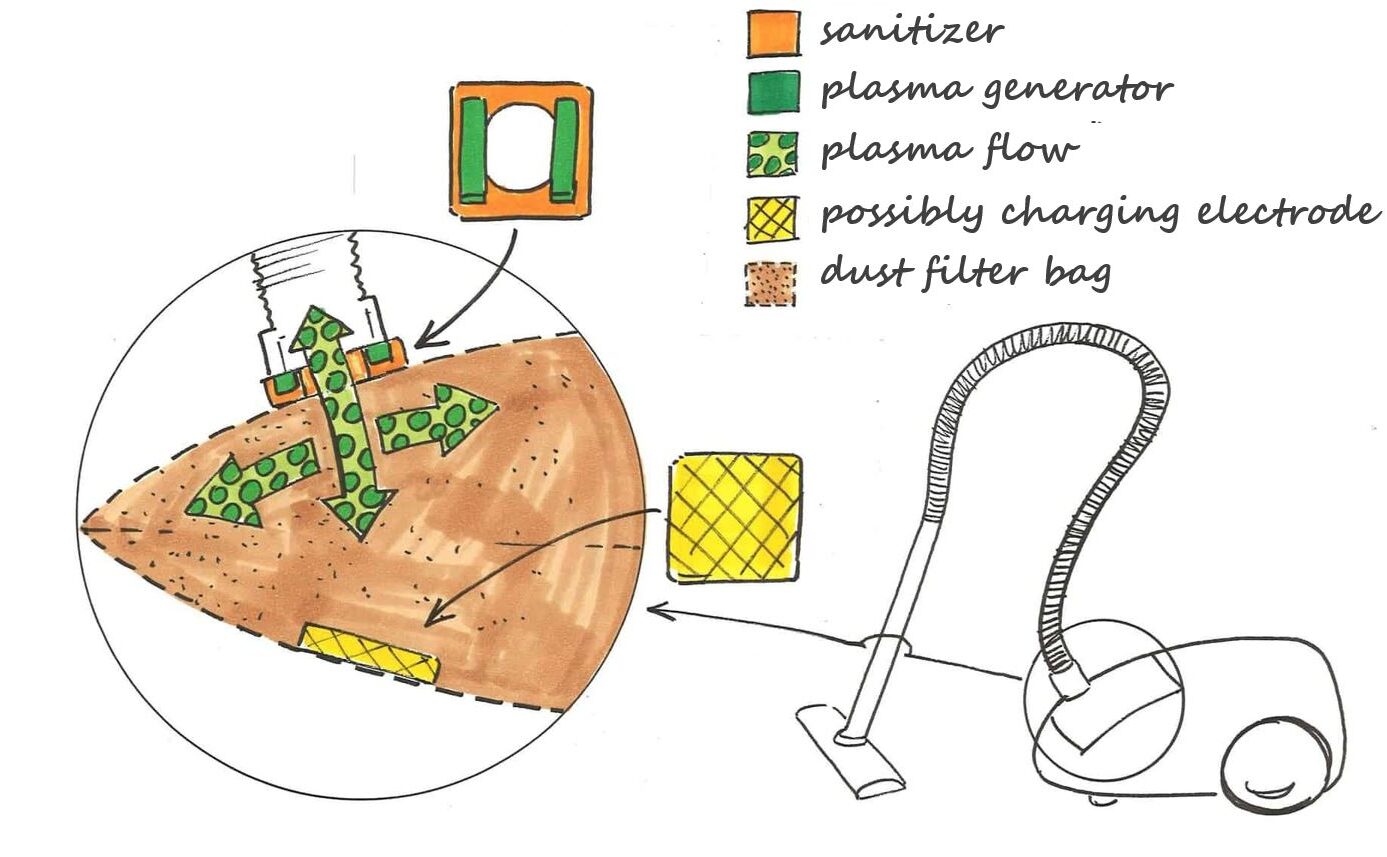

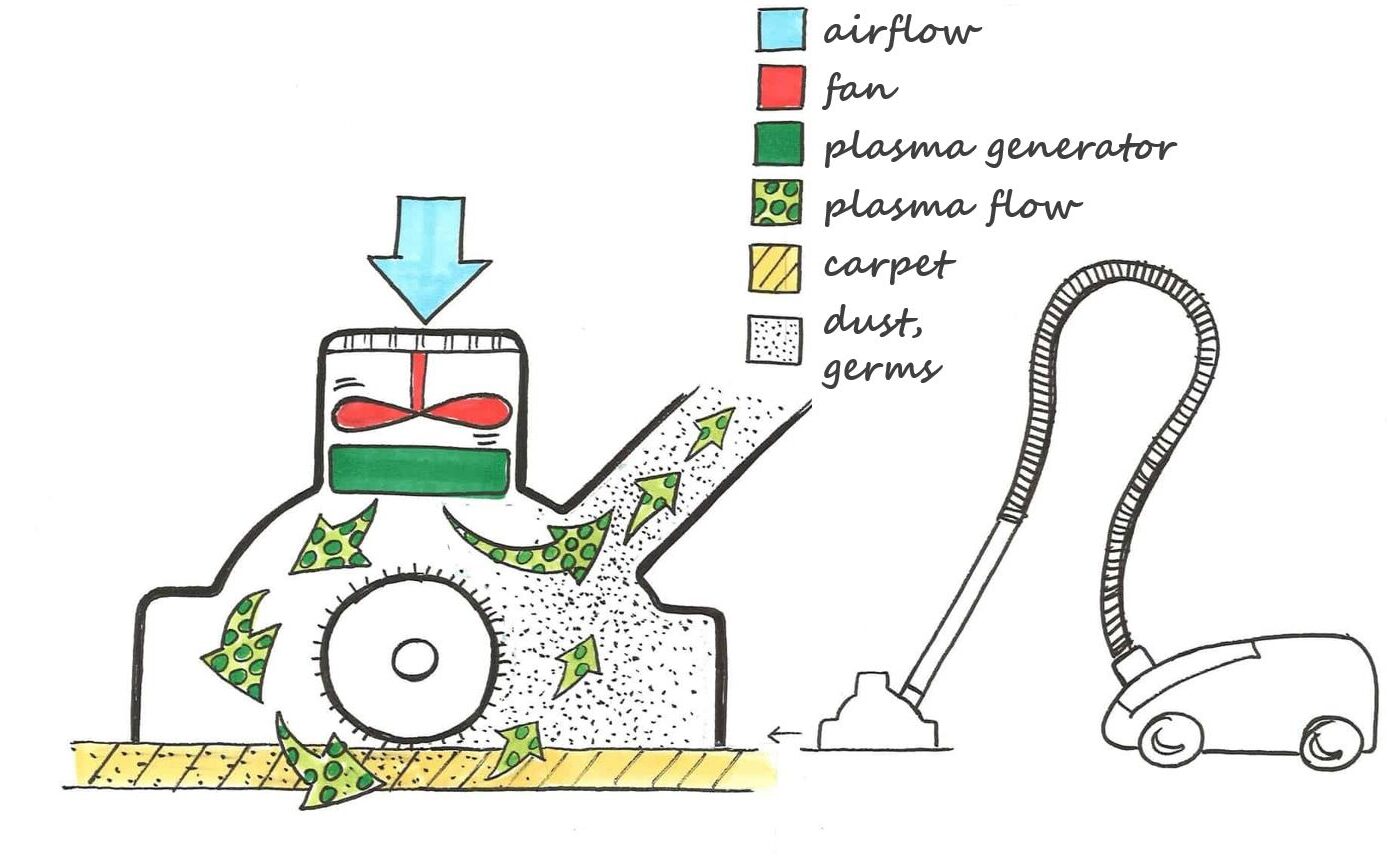

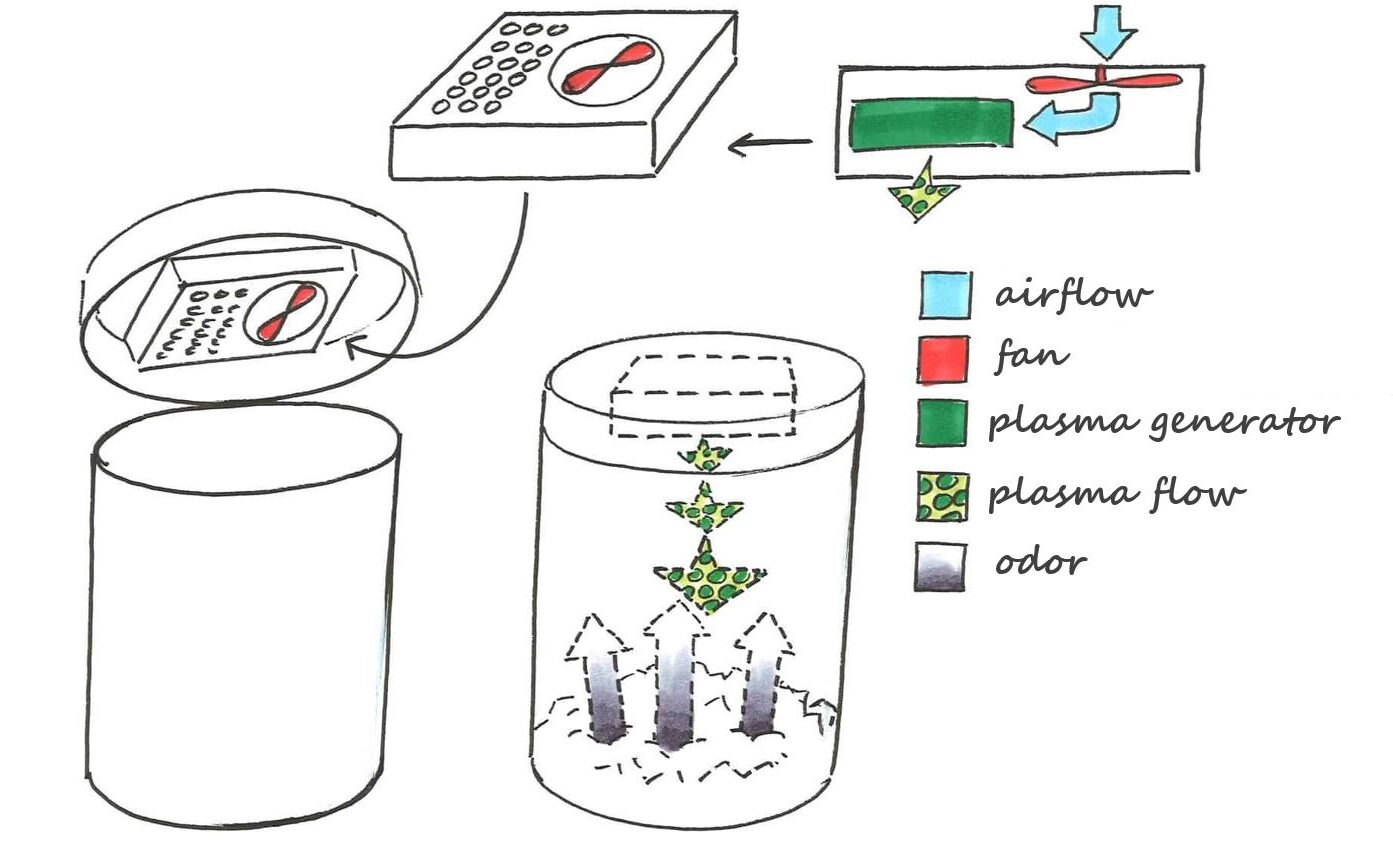

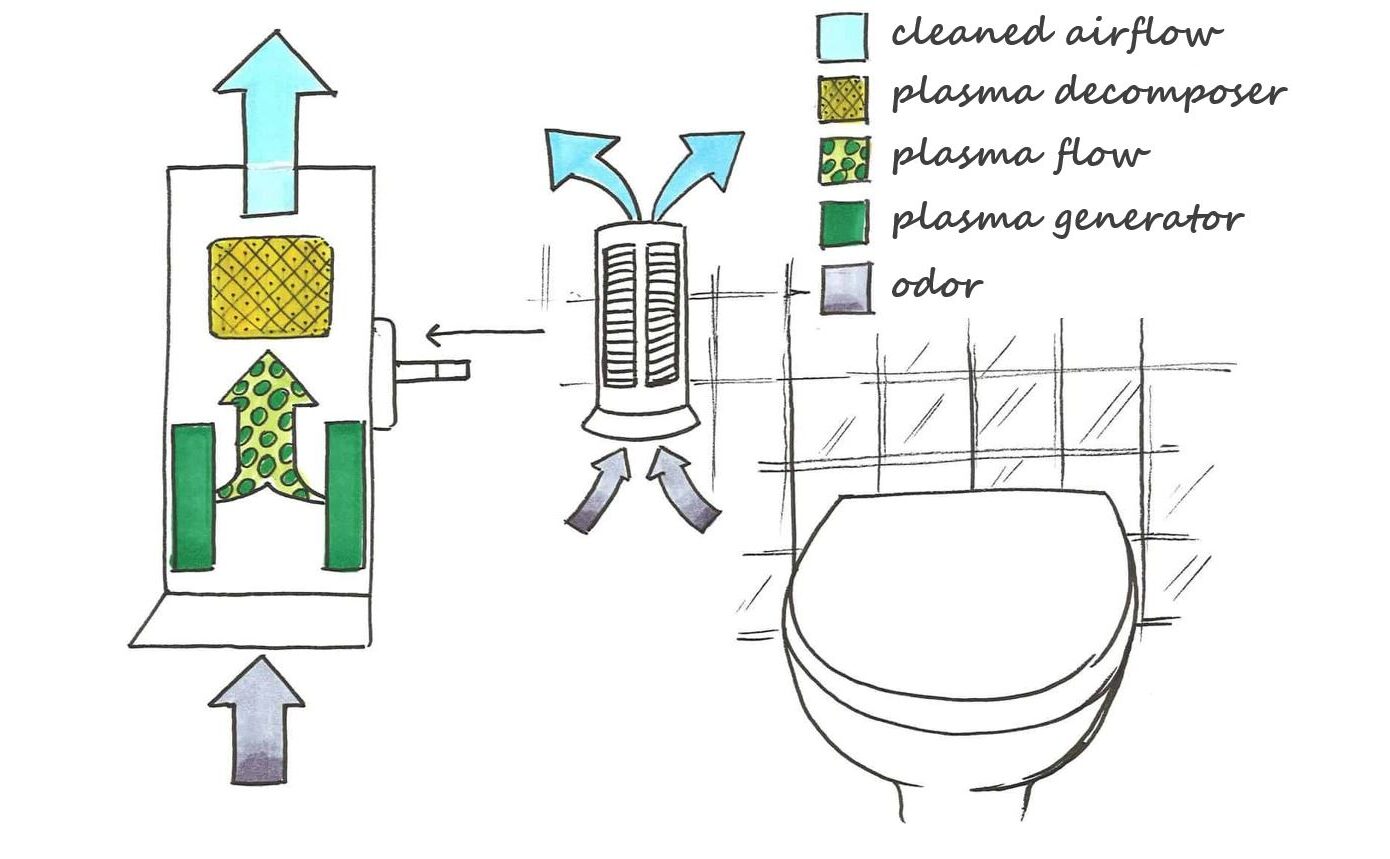

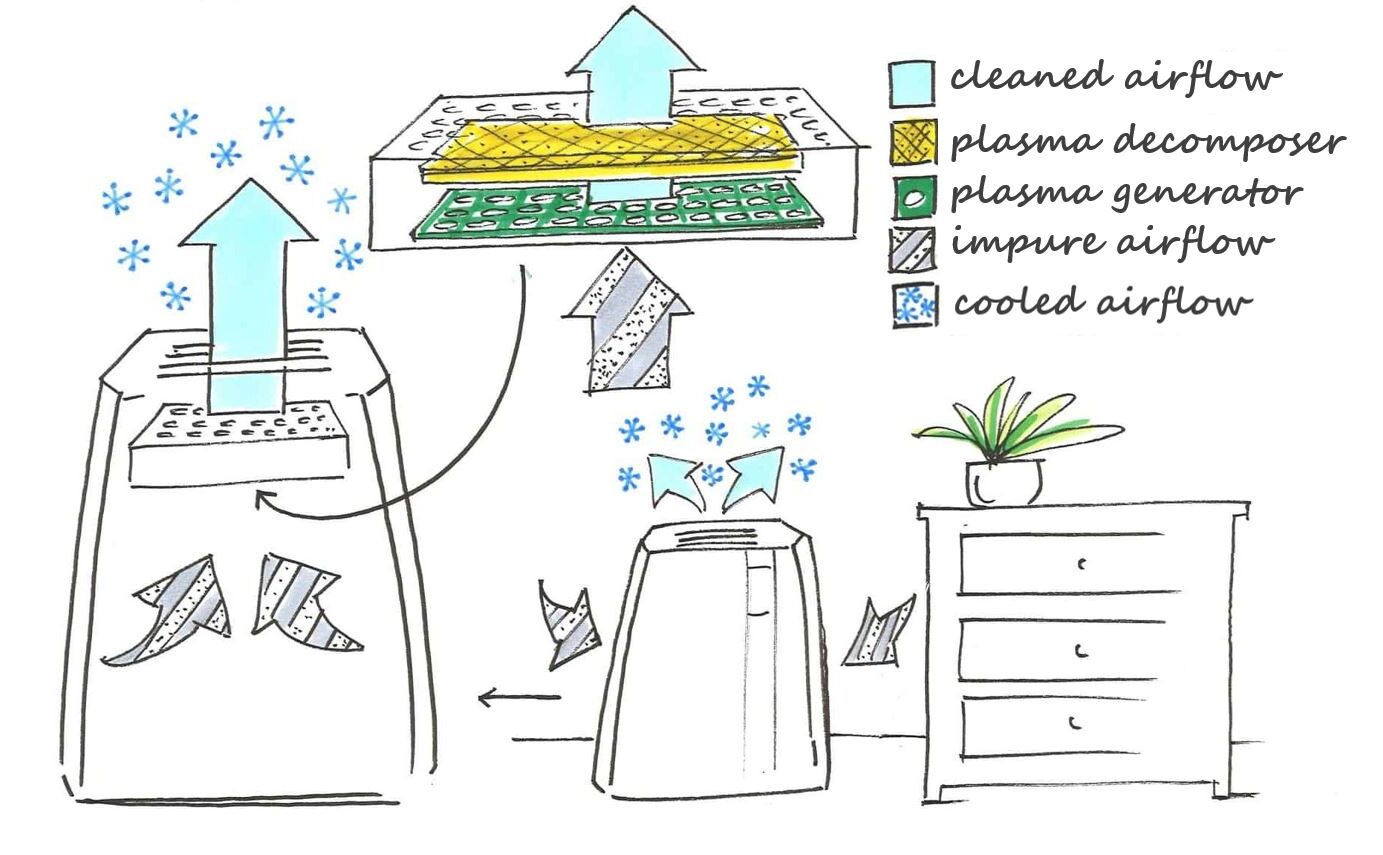

Applications of the ozone generator

- Pharmaceutical industry

- Packaging industry

- Food and beverage industry

- Agriculture industry

- Automotive industry

- Medical technology

- Dental sector

Use in Cleaning in Place

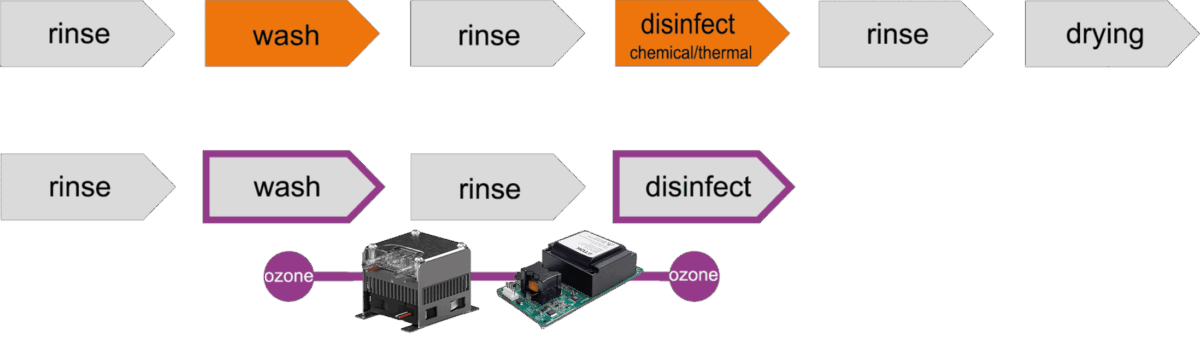

The cold atmospheric plasma components can be used wherever hygiene is an important consideration. This can be optimized by incorporating ozone into Cleaning in Place (CIP). Instead of the typical six steps, only four steps are required due to the incorporation of ozone.

Cleaning in place is a method for cleaning continuous processes without dismantling the system. The method was originally developed for the food, beverage and pharmaceutical industries. But the principle can also be used in medical technology.

Sterilisation in Place (SIP) is mainly used in pharmaceutical and biological production facilities and serves not only to clean but also to sterilise the system. Usually, sterilisation takes place through superheated steam or with special chemicals. The cleaning or sterilisation cycle can be optimised on site by integrating ozone into the process.

Applications in the medical field

The MediPlas system can also be used for disinfection in medical technology. You can find further information on its use in the medical sector on the website of our parent company TDK Electronics: MediPlas landing page

Technology

- High durability; easy integration

- High ozone concentration

- Stable against humidity

- Operates with pure (medical) oxygen to provide high ozone concentrations > 50,000 ppm. High oxygen concentrations can also be provided with pressure swing absorption (PSA).

- High NOx operation for inline fertilization for plants.

Technical data of the driver for ozone generators

- Typical input power: 10 – 30 W

- W x H x L: 68 x 39 x 114 mm

- Weight: 460 g

- Reference signal: Analog 0 to 5 V

Advantages

- High efficiency

- Temperature, over- and undervoltage protection as well as overload protection (auto recovery)

- Compact size

- Easy integration into the device

- Simple power control

- Process monitoring signal

- Wide range of usable loads

- Made in Germany

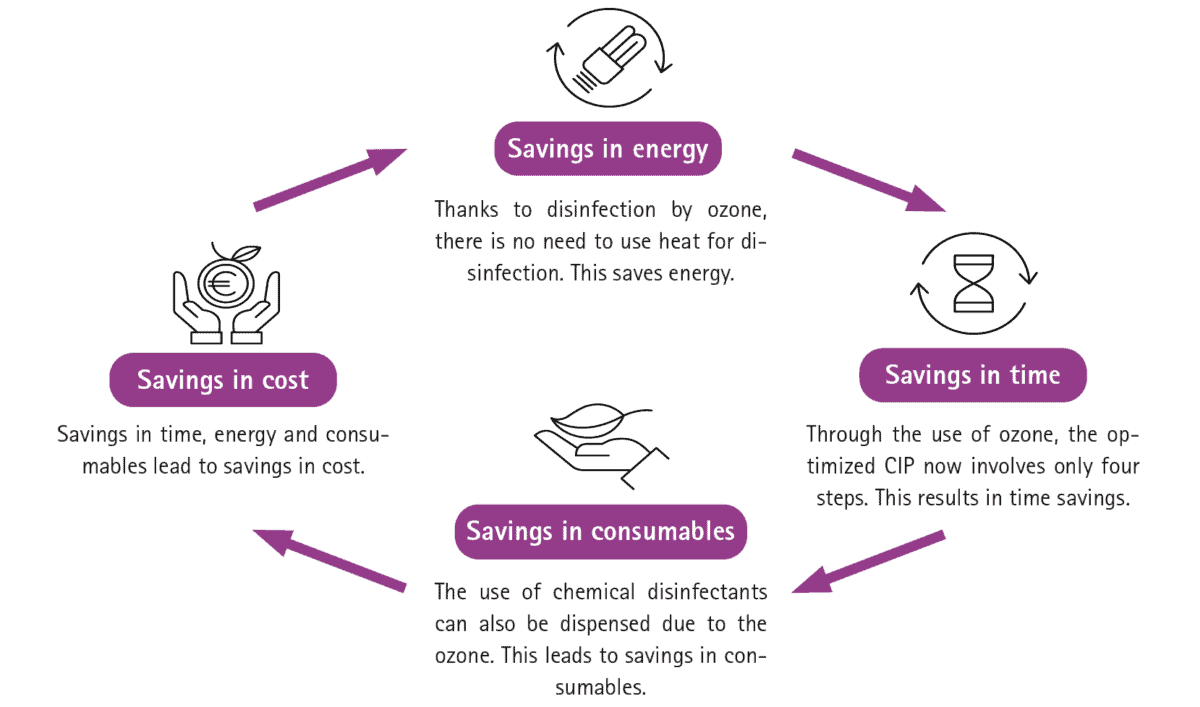

Advantages of the MediPlas system for end customers

- Low cost per cycle

- Avoidance of chemicals

- Short process time

- Environmentally friendly

- No use of consumables

Would you like to learn more about the MediPlas system? Then take a look at the product page of our parent company TDK Electronics.

Learn more >>Downloads

| Beschreibung/Description | Sprache/Language | Download |

|---|---|---|

| Flyer MediPlas | EN | Flyer |

| Flyer MediPlas | DE | Flyer |

| Data sheet MediPlas Reactor | EN | Data sheet |

| Data sheet MediPlas Driver | EN | Data sheet |