Customer Reference: FaSTTUBe Formula Student Team, TU Berlin.

Plasma pretreatment for bonding PEEK cell holders.

The Formula Student Team at the Technical University of Berlin (FaSTTUBe) has been developing prototypes for electric racing cars since 2005. The students rely on PEEK, a high-performance material with ideal properties for racing car construction – but the bonding of which presents a particular challenge. In order to ensure secure connections, the team resorted to plasma pre-treatment.

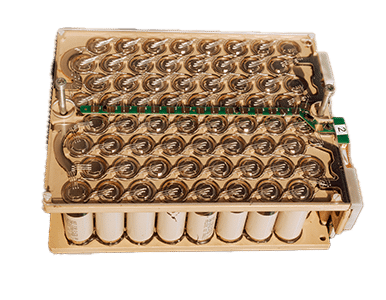

One of the central components is the high-voltage battery module, which fulfils the highest requirements in terms of high safety, excellent reliability and low weight. The team designed a CNC-milled cell holder made of PEEK (polyether ether ketone) to accommodate cylindrical lithium-ion cells. The high-performance polymer offers excellent mechanical stability, electrical insulation and fire protection in accordance with UL94 V-0. At the same time, however, it is difficult to bond reliably due to its low surface energy.

The bonded assemblies must be able to withstand racing conditions, vibrations and impact loads of up to 40 g and function reliably at operating temperatures of up to 60 °C. The central question was therefore: How can a permanently robust and secure bonded connection of PEEK be realised?

Solution: Plasma pre-treatment with the PiezoBrush PZ3

In order to significantly increase the adhesive strength, the FaSTTUBe team relies on plasma pre-treatment with the PiezoBrush PZ3 handheld device from relyon plasma.

Before bonding, the PEEK surfaces are first mechanically roughened and cleaned with solvent. This is immediately followed by manual plasma activation of all bonding surfaces. This step significantly changes the surface properties of the PEEK: the surface energy increases, which optimally wets the two-component epoxy adhesive and enables a permanent chemical bond.

The adhesive is applied and cured within 30 minutes of treatment. In tensile shear tests according to ISO 4587, the pretreated samples achieved an average shear strength of 8.5 MPa.

Result: Reliability in racing practice with secure bonded joints thanks to plasma pre-treatment

After curing, the battery modules undergo dimensional tests, high-voltage insulation measurements and functional vibration tests under accelerated conditions. To date, the plasma-treated adhesive joints have shown consistently high performance in racing – without delamination or cracking of the adhesive layers.

Another advantage lies in sustainability: recycled PEEK is used for the cell holders, which, in combination with precise CNC production and plasma pre-treatment, results in a resource-saving yet high-performance overall concept.

Interview with Sebastian Freund – Formula Student Team TU Berlin

In an interview with Sebastian Freund from the Formula Student Team at TU Berlin (FaSTTUBe), Mr Freund explains the particular challenges involved in bonding PEEK components and how relyon plasma’s plasma technology made a decisive contribution to the solution.

1. Could you please briefly introduce yourself and your team?

FaSTTUBe is the TU Berlin’s Formula Student Team, in which around 100 students from engineering, business and design disciplines develop and build an electric racing car every year. They take care of every step of the process – from CAD design and simulation to in-house production of the chassis, drive and electronics through to driving tests. In the summer, the team takes part in Formula Student competitions in Europe, gaining valuable practical experience that goes far beyond lecture theatre knowledge.

2. For which of your components do you use plasma pretreatment? Can you describe the material and application purpose?

We use PEEK for the cell holders of our battery modules. In order to securely fix the lithium-ion cells in the racing car, they are glued to the PEEK cell holders on both sides. This creates a stable battery module that can withstand the forces of an impact in an emergency.

3. At what point in your production process is plasma treatment used? What steps are required before and after?

Plasma pre-treatment is carried out immediately before joining with a 2-component epoxy adhesive (SikaPower 752 L120 FR). Beforehand, the material is mechanically roughened (grain size 240-320) and carefully cleaned with the cleaner recommended by the adhesive manufacturer (SIKA Cleaner 208). Immediately after plasma activation, the adhesive is applied and bonding is carried out.

4. Why did you decide in favour of the PiezoBrush PZ3 system from relyon plasma?

The easy handling and flexible application without complex systems make the system very attractive for our prototype construction. It does not require lengthy familiarisation and is also much less harmful to health than some chemical processes for adhesive pre-treatment. The compact design also proves to be a great advantage in our workshop.

5. What advantages do you see compared to alternative processes or competing products?

We did not test other competitor products. The decisive factor for us was that the plasma treatment enables a significant improvement in adhesive quality – and at the same time simple, safe handling.

6. What challenges in the production process were you able to solve with plasma treatment?

PEEK is a high-performance plastic that is characterised by high strength, low weight, electrical insulation and temperature resistance. However, it is difficult to bond reliably due to its low surface energy. Plasma pre-treatment enabled us to significantly improve the adhesive properties: In tensile shear tests, only material failure occurred in the PEEK itself, but not adhesion failure on the bonding surface.

7. Where do you see further potential for the use of plasma in your industry?

We see great potential for further optimising the properties of highly stressed or safety-relevant bonds in particular through plasma pre-treatment and increasing the reliability of joints in the long term.

Thank you for the interview with Sebastian Freund.

About FaSTTUBe

The Formula Student Team at TU Berlin unites students from a wide range of disciplines in the development of innovative racing cars. With creativity, engineering expertise and consistent testing processes, FaSTTUBe has been able to realise high-performance electric racing cars for almost two decades. The current vehicle with a fully electric drive train emphasises the team’s claim to efficiency, reliability and safety.

https://fasttube.de

Conclusion

The FaSTTUBe team’s experience impressively demonstrates how even challenging materials such as PEEK can be reliably and permanently bonded using plasma pre-treatment. The result is highly reliable battery modules that prove their performance even under extreme racing conditions – and at the same time support a sustainable overall concept through the use of recycled PEEK. This makes it clear that plasma activation not only creates connections, but also solutions for the future of lightweight construction and electromobility.

Further use cases in e-mobility

Plasma in electronics industry

In order to optimally prepare the surfaces of various materials for adhesion processes, plasma is increasingly being used in electronics industry.

Semiconductor components and plasma

Blickfeld GmbH from Munich reports on their experiences with plasma and semiconductor components with the piezobrush PZ2.

Plasmatool at Roding Automobile – passion unites

Roding Automobile GmbH is an internationally active technology company in the field of lightweight construction and electromobility. Read how they use plasmatechnology.