Piezoelectric Direct Discharge Technology – PDD Technology®

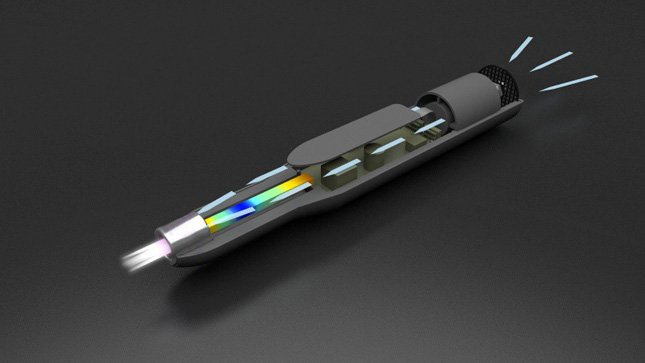

For the particularly compact plasma generation relyon plasma has developed the Piezoelectric Direct Discharge (PDD®) technology. This technology is based on the direct electrical discharge at an open piezoelectric transformer (PT). The heart of the technology is the TDK CeraPlas™ plasma generator, a high-voltage discharge component for compact plasma generation.

With maximum efficiency, a low input voltage is transformed to generate very high electric field strengths. This dissociates and ionizes the surrounding process gas, which is typically ambient air. The gas temperature in the plasma volume of PDD® typically corresponds to the ambient temperature. In addition, the electron densities reach approx. 1014 and 1016 m-3 . Thus PDD® provides a typical “cold” non-equilibrium plasma.

Applications Piezoelectric direct discharge technology

These features of PDD® technology open up a wide range of different applications. Probably the most popular plasma system based on PDD® technology is the PiezoBrush PZ3 handheld plasma device. With a maximum power consumption of 30 W the plasma handheld generates cold active plasma with a temperature of ~ 50°C.

The PiezoBrush is particularly suitable for use in laboratories, professional model making and manual assembly of small series. Typical industrial applications include surface activation to optimize wetting and adhesion properties for subsequent processes such as bonding, printing or painting.

PDD® technology is also used in medical research, for germ reduction, odour reduction and in microbiology.

Products with PDD technology

Application examples

White paper: Lifetime of the Standard Module

The lifetime of the Standard Module for the piezobrush® PZ3 and the piezobrush® PZ3-i was verified for 6000 h using an endurance test.

Piezoelectric Direct Discharge

The piezoelectric direct discharge (PDD) is a comparatively new type of atmospheric pressure gaseous discharge for production of cold plasma.

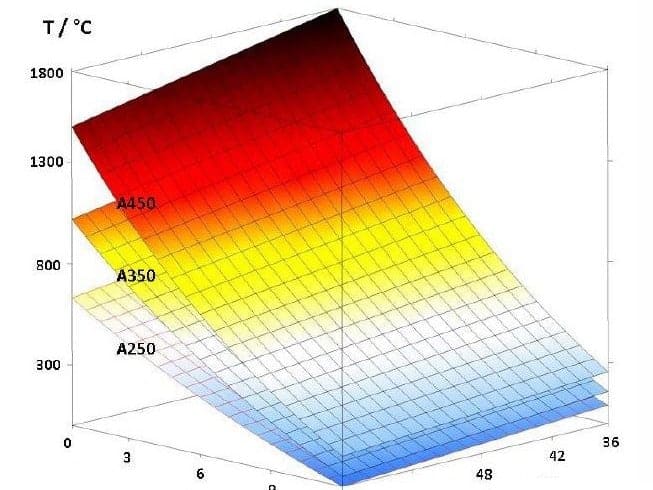

The high temperatures which are reached in most plasma applications make many users wonder about process safety, especially when highly sensitive materials are treated. This article addresses open questions concerning temperature and heat conduction during plasma applications and cites critical examples which substantiate the suitability of plasma for temperature-critical processes.

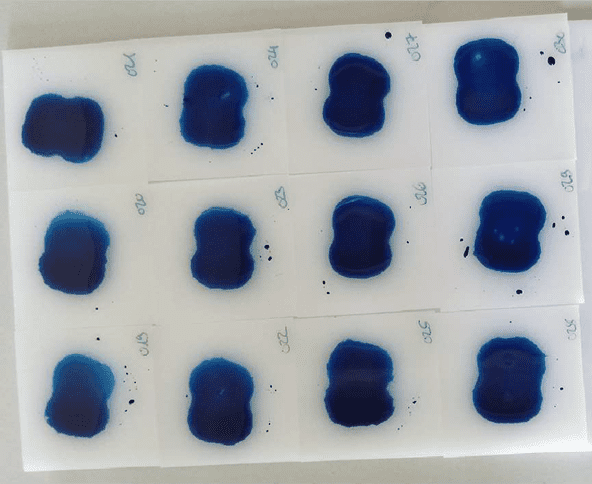

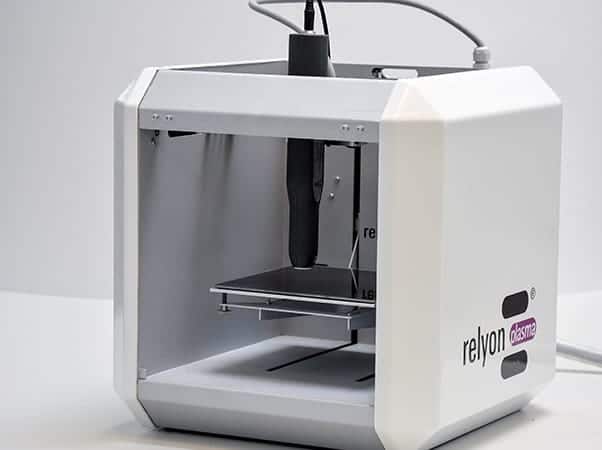

Maximum surface quality in 3D printing

PDD® Plasma technology improves surface texture and wettability. It is suitable for integration into 3D printers of all kinds and categories of performance.

New applications for piezobrush® PZ2

The new nozzles for piezobrush PZ2 enable applications which were not possible with the standard version of this product.