Pulsed Atmospheric Arc Technology – PAA Technology®

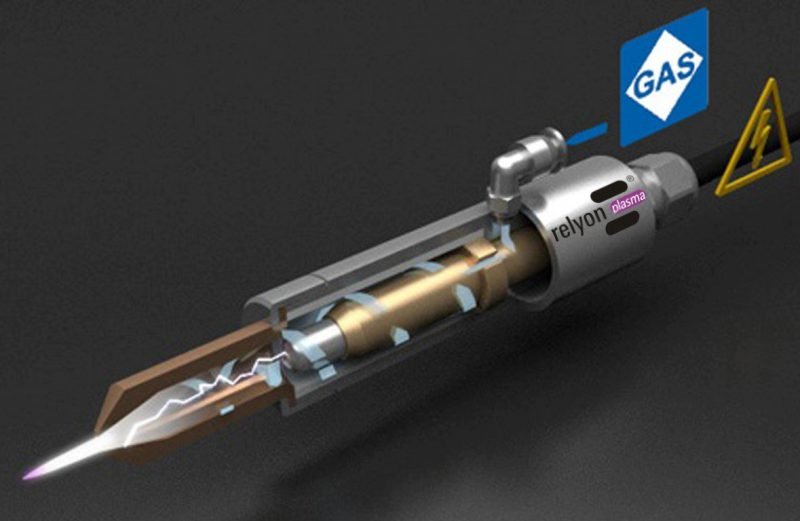

The use of atmospheric plasmas for industrial applications has become widespread in many different sectors. Relyon plasma develops nozzle-type plasma generators which are particularly compact and offer long-term stability. Through the use of a unipolar pulsed high voltage source and a vortex flow in the nozzle, the arc is prevented from stabilising at a “hot spot”.

In PAA (Pulsed Atmospheric Arc) Technology®, the generation of a plasma jet is based on the ignition of an electric arc between two electrodes by means of pulsed high voltage. To stabilize this arc, a vortex is created along the two electrodes by a gas flow, which makes the arc rotate on the nozzle-shaped cathode. This gas, typically compressed air or nitrogen, is ionized as it passes close to the arc. This creates a plasma flame of highly reactive gaseous species that react with the top atomic layers of the component surface. Depending on the gas type selected, the majority of these reactive compounds are either oxygen or nitrogen based. When using compressed air as process gas the oxygen content in the plasma leads to the generation of polar end groups on the treated surfaces. This functionalization is even macroscopically noticeable by an improved wetting with polar solvents like water.

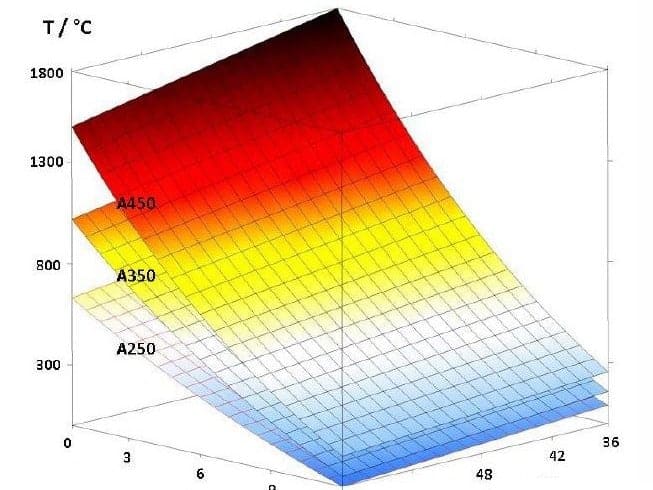

With an optimized parameter set, the positive properties of the reactive plasma species on the surface can be utilized and undesired thermal over-treatment can be prevented. In addition, such systems operate at high power consumption in the kilowatt range, which allows high process speeds on the one hand, but makes protective measures absolutely necessary on the other.

For example, the plasma nozzle is not safe to touch during operation and, in addition, nitrogen oxides are produced which must be reliably extracted.

PAA® technology requires automation, for example in the treatment of plastics, in order to relativize the thermal effect on the substrate by means of defined process speed and fixed distance to the plasma nozzle.

Despite the high power density, there is only minimal warming of the nozzle and hardly any erosion of the electrodes. The plasma temperature can be freely adjusted across a wide range.

Application Pulsed Atmospheric Arc Technology

The properties of PAA® technology open up a multitude of different application possibilities. For example, this plasma technology is the basis of PlasmaBrush PB3 – the high-performance plasma system that is used whenever fast processes require the highest performance.

In most cases, this system is directly integrated into inline processes in industrial and high-speed applications. However, this system is also available as PlasmaTool handheld unit, which allows flexible and easy surface treatment in industrial applications.

Products with PAA technology

Application examples

The high temperatures which are reached in most plasma applications make many users wonder about process safety, especially when highly sensitive materials are treated. This article addresses open questions concerning temperature and heat conduction during plasma applications and cites critical examples which substantiate the suitability of plasma for temperature-critical processes.

Real-time analysis of atmospheric plasma processes

Our Plasmabrush® system, particularly the PS2000 high voltage unit, supplies meaningful digital process data from which valuable process information can be gained based on our years of expertise. In close collaboration with you, we define the operating points for your production steps and provide a working area designed to achieve the desired results.

TDK cooperates with relyon plasma to develop and manufacture cutting-edge plasma solutions