relyon plasma GmbH – A TDK Group company

relyon plasma offers a wide range of specialized plasma components for manual applications and inline processes. Atmospheric pressure plasmas, which are generated by electrical discharges in air or other gases, have a remarkable combination of properties that allow unique surface treatment. Such plasmas produce large quantities of very reactive but short-lived chemical species. These can disinfect, clean, modify and functionalize a wide range of surfaces, preparing them for bonding, painting and printing. Our plasma components can also be used for disinfection in medical technology. Harness the power of plasma technology for surface treatment!

rely on plasma. relyon plasma.

News

The PlasmaBrushPB3 is our high-performance plasma system for all inline processes in industrial and high-speed applications. The plasma system is widely used in the automotive, packaging and printing industries. The main focus here is on plasma cleaning and surface activation.

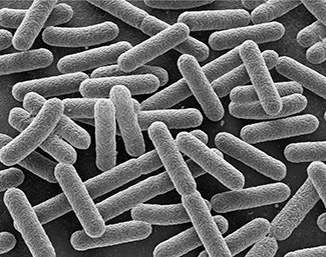

MediPlas reduction

The MediPlas Reactor has been developed as a component for disinfection and sterilization in medical technology and industry, among other things. Experiments show that, depending on the type of bacteria, the MediPlas system achieves a reduction of more than 6 log levels in the number of living cells after just 5 minutes or a maximum of 15 minutes of treatment time.

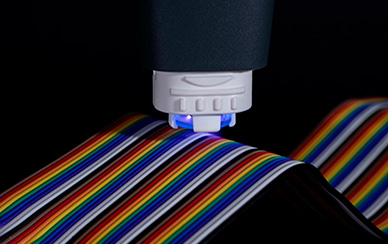

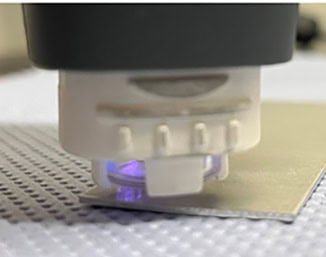

PiezoBrush PZ3-i

The PiezoBrush PZ3-i is the compact plasma integration as the industry standard of the future. It impresses with intuitive operation, comprehensive process control in automated production processes and is designed to be compact, safe and efficient.

PiezoBrush PZ3-i >>About relyon plasma

Relyon plasma GmbH, headquartered in Regensburg, a subsidiary of TDK Electronics AGdevelops innovative plasma systems. Parallel to our own products for the plasma treatment for industrial and medical applications, relyon plasma develops customized, highly efficient process solutions for surface cleaning, surface activation, precision cleaning and germ reduction. True to the motto “rely on plasma” we see ourselves as a professional service provider for individual customer requirements.

Simona Lerach und Florian Freund

relyon plasma international – our partners

Good to know

Application: Disinfection

Plasmas reduce concentrations of pathogens upon contact with contaminated surfaces. Plasma destroys bacteria, viruses, fungi and prions; it also removes toxins and further organic contaminants.

More about printing >>References

The PiezoBrush PZ3 was used by a German sports car manufacturer for the surface treatment of anodized aluminium test specimens, some of which were oiled with lubricating grease. Plasma activation of the aluminum surface greatly increased the tensile shear strength.

FAQ

In our FAQ section you will find a large number of frequently asked questions about plasma in general and relyon plasma plasma systems in particular. Immerse yourself in the exciting world of plasma technology and learn how you too can improve your processes and the quality of your products by using plasma.