Pre-treatment of plastic films with piezobrush® PZ3

for the creation of intelligent polymer surfaces by e-grafting

The Institute of Polymer Nanotechnology (INKA) at the University of Applied Sciences and Arts Northwestern Switzerland (FHNW) is investigating the functionalization of plastic surfaces by means of structuring and chemical modification. Dr. Sonja Neuhaus, together with her two project team members Nika Petelinsek and Dr. Alok Goel, investigated the pre-treatment of plastic films with the piezobrush® PZ3 during the beta test phase. The motivation for this is the project on “Immobilization of enzymes with electron beam assisted grafting (e-grafting) for intelligent polymer surfaces”.

Here, aqueous, functional polymer solvents are to optimally wet different polymer surfaces. The wettability of the solvents should not be changed by the addition of surfactants, as this would have a negative effect on the function of the enzymes. In order to be able to functionalize as many different substrates as possible, the piezobrush® PZ3 is used to increase the surface energies of plastic films that are difficult to wet. The tests showed that the piezobrush® PZ3 is very well suited to significantly improve the wettability of small-format samples of the following materials: Polyethylene terephthalate (PET), Polymethyl methacrylate (PMMA), Polypropylene (PP) and Polyethylene (PE). Especially the flexibility and mobility of the plasma handheld device convinced the researchers, as they can transfer the samples directly into the e-grafting process without delays.

Motivation and objectives

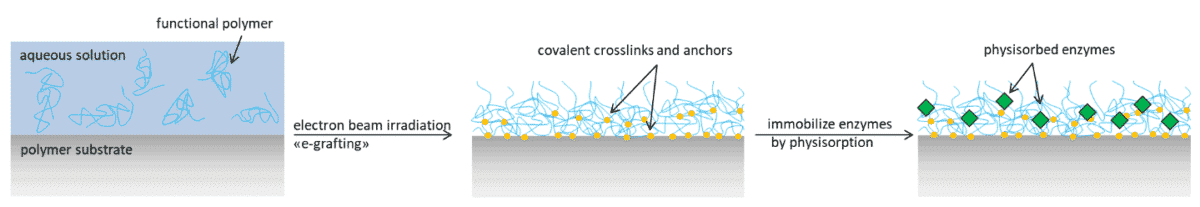

The project “Immobilization of enzymes with electron beam assisted grafting (e-grafting) for intelligent polymer surfaces”, funded by the Swiss National Science Foundation (SNSF), provides the context for the investigations with the piezobrush® PZ3. E-grafting could become a revolutionary technology in surface functionalization by using low energy electron beam emitters. Electrons break chemical bonds and are thus the initial trigger for new covalent bonds between substrate and the graft materials.

For the immobilization of enzymes on plastic surfaces, a favorable environment for enzymes is to be created by grafted layers. The researchers are also investigating whether enzymes can be bound directly to the surface by e-grafting.

The e-grafting method is extremely attractive due to its energy efficiency, the possibility to irradiate in air and the complete absence of organic solvents or toxic ingredients. Additionally, only the surface is modified without affecting the bulk of the material. The potential of intelligent surfaces is huge, but has only been partially tapped to date. Especially decisive for the consumer is the possibility to make processes and products more informative and safer.

For the e-grafting process aqueous solvents of functional polymers are used. These often do not sufficiently wet the mostly hydrophobic polymer films. The problem can basically be solved by adding isopropanol or surfactants to lower the surface tension of the coating solvents. In the current project, however, surfactants are undesirable, as they can negatively influence the function of the enzymes. In order to be able to functionalize a large number of substrates nevertheless, a series of experiments to increase the surface energy is being carried out within the framework of this beta test. The overall objective is to improve the wettability of the functional polymer solvents by plasma treatment of the substrates with the piezobrush® PZ3.

Validation and analysis methods

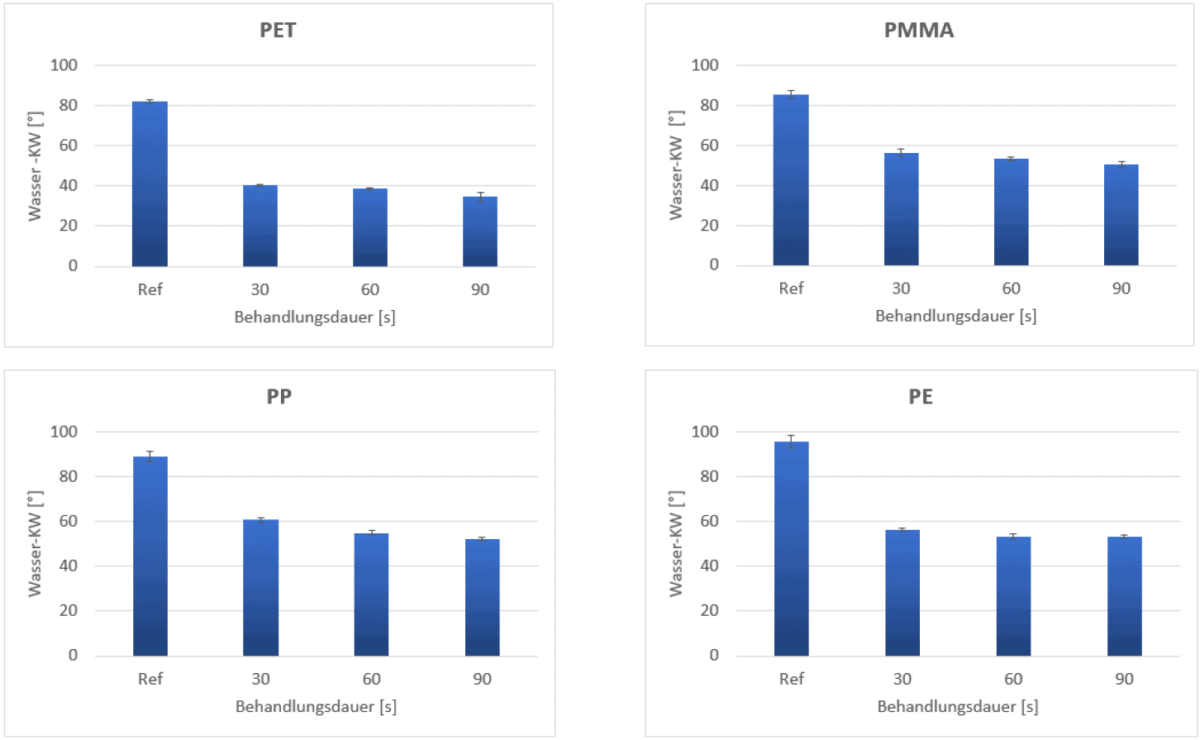

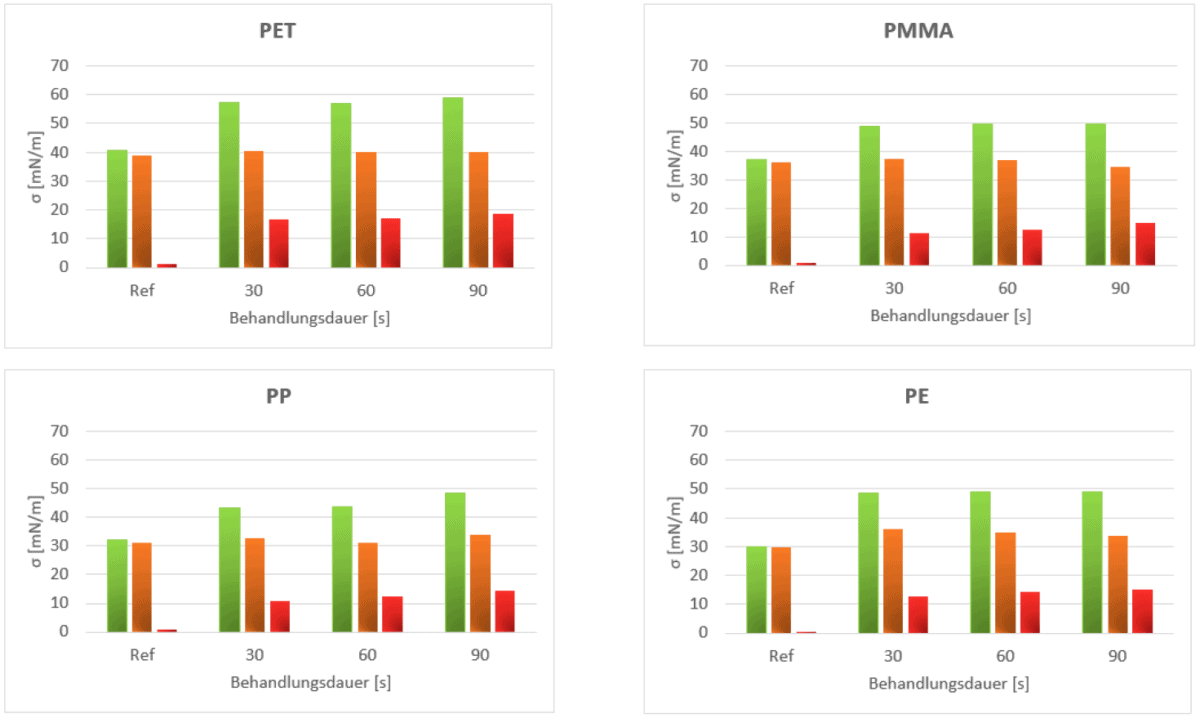

Four film substrates are treated with the piezobrush® PZ3: Polyethylene terephthalate (PET), Polymethyl methacrylate (PMMA) and the two Polyolefins Polypropylene (PP) and Polyethylene (PE). The samples each have a format of 4 cm x 4 cm. After cleaning with isopropanol, the samples are treated for 30 s, 60 s or 90 s. The contact angles of water, diiodomethane and ethylene glycol are then determined with a Krüss DSA at five sites per sample. The contact angle measurement is performed shortly after the treatment (i.e. after 0.5 h) and after 3 and 6 hours. New samples are used for each measurement to prevent cross-contamination by the test liquids. The surface free energy is calculated with the method of Owens-Wendt-Rabel and Kaelble (OWRK). For a phenomenological evaluation, the researchers compare the wettability of polymer films before and after the plasma treatment. For this purpose, a small amount of solution is applied to the film with a squeegee and the wetting is qualitatively evaluated.

Results and discussion

The water contact angles of the untreated samples are between 80° (PET) and 96° (PE), which explains the poor wettability with aqueous solvents. The treatment with the piezobrush® PZ3 leads to a significant reduction of the contact angles (Fig. 2). The difference before and after the treatment is particularly evident for PET with a contact angle of about 40°. For all films the hydrophilic wettability regime can be achieved. The treatment duration plays a subordinate role here; however, in principle, lower contact angles are achieved with longer treatment duration.

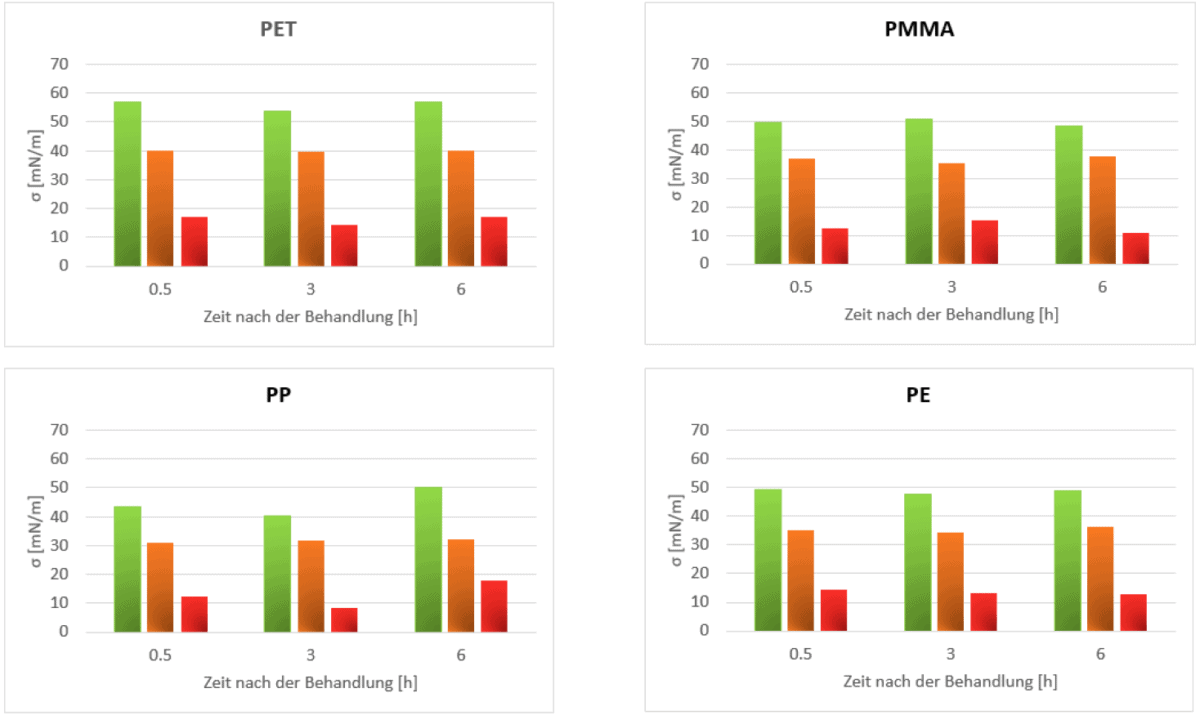

With the contact angles of ethylene glycol and diiodomethane the surface energy and its components are calculated (Fig. 3). With 30 mN/m (polyolefins) to 40 mN/m (PET) the untreated materials have low surface energies. The polar fraction is negligible in all cases. Treatment with the piezobrush® PZ3 can increase the surface energy for PET to the maximum value of 59 mN/m, for PMMA and PE to around 50 mN/m and for PP to 43 mN/m. The polar component increases massively for all materials and is practically the only one responsible for the increase in total surface energy. Here, too, only a slight dependence on the duration of treatment is apparent. For PP, the surface energy can be slightly increased with increasing treatment duration.

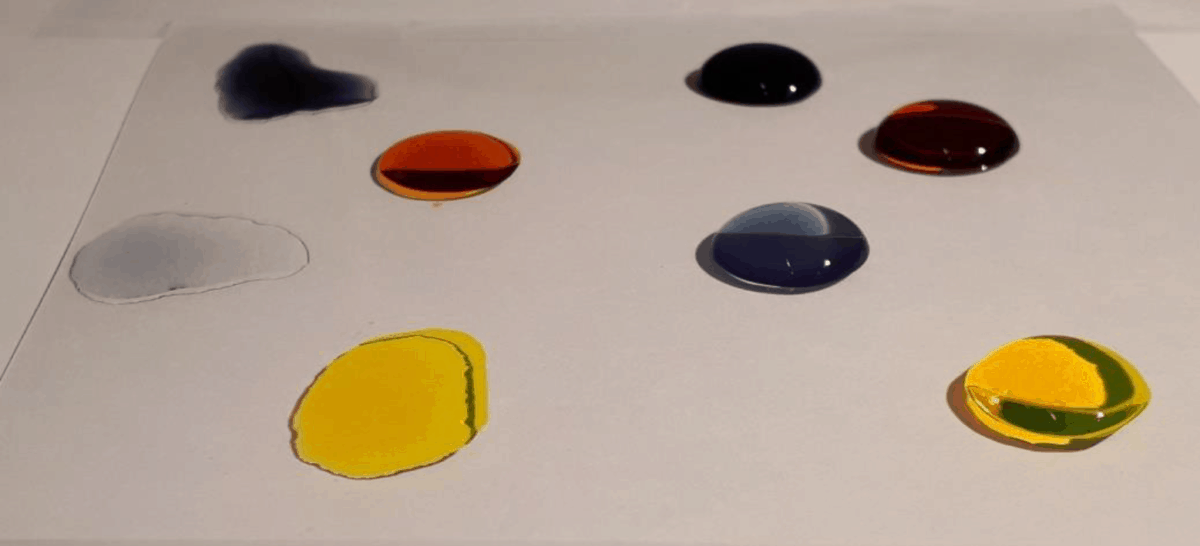

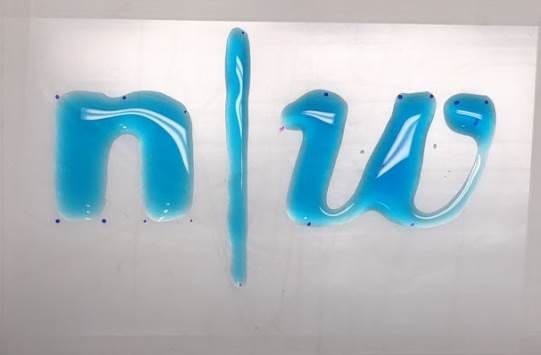

The strongly improved wettability can also be observed phenomenologically when applying polymer solvents (Fig. 4). By masking during pre-treatment, certain areas can be selectively activated. These areas are then much better wettable, as shown by the example of a PP film with different mask geometries (Fig. 5). Only the treated areas are wetted by the colored aqueous solvents.

Activated surfaces are often subject to aging phenomena such as the so-called “hydrophobic recovery”. To define the time window for further processing, the surface energy is additionally determined 3 and 6 hours after plasma treatment. It was found that no major changes in surface energy occur during this period (Fig. 6). Only for PP a significant increase occurred unexpectedly after six hours, which cannot be explained from today’s point of view.

Conclusion and outlook

In the researchers’ opinion, the piezobrush® PZ3 is very well suited to significantly improve the wettability of small-format PP, PE, PMMA and PET samples. The piezobrush® PZ3 fully met the expectations of Dr. Neuhaus’ team and convinced them with its easy handling. The group will use the piezobrush® PZ3 to pre-treat the samples prior to coating by means of e-grafting: “The great flexibility and mobility of the piezobrush® PZ3 allows us to carry out the pre-treatment directly at the electron beam emitter, so we do not lose any time due to long distances”.