MediPlas Evaluation Kit

The MediPlas Evaluation Kit for system developers can be used to generate an atmospheric pressure air plasma from which gases with a variable composition of reactive oxygen and nitrogen species (RONS) can be generated.

The MediPlas Evaluation Kit provides a development platform for the MediPlas reactor and MediPlas driver. Typical applications for this solution include:

– food production and packaging

– agricultural engineering (seeds, sprouts)

– pharmaceuticals

– material testing

– air treatment

– tobacco production and packaging

– medical product packaging

– water treatment

– wastewater treatment

– odor neutralization

Both components are available from well-known electronics suppliers, such as DigiKey or Mouser. However, the components alone are not sufficient to build a fully functional system. To make the task easier for a system developer working based on the MediPlas platform, relyon plasma offers the MediPlas Evaluation Kit. The target groups are primarily research laboratories, standardization institutes, material testing laboratories, didactics/vocational training, PAW manufacturers, and many others. This plug-and-play board enables the generation of a remote plasma with a variable composition of reactive oxygen and nitrogen species (RONS).

Ozone is a possible, but not the only product from the MediPlas-Reaktor. If compressed air is used as the initial gas, it contains oxygen, nitrogen, and water. Therefore, many RONS are to be expected. Fourier transform infrared spectroscopy (FTIR) was used to detect the long-lived molecules O3, NO2, N2O, and N2O5 in the MediPlas remote plasma. The presence of humidity in the air allows the formation of hydrogen-containing compounds such as HNO3 and H2O2.

The composition of the MediPlas remote plasma is strongly influenced by the process conditions, such as voltage, pulse modulation (PWM) duty cycle, temperature, and gas composition. For example, at very high humidity or very high power without cooling, hardly any ozone is produced, but more nitrogen oxides are produced.

The potential areas of application are described in detail on the MediPlas website.

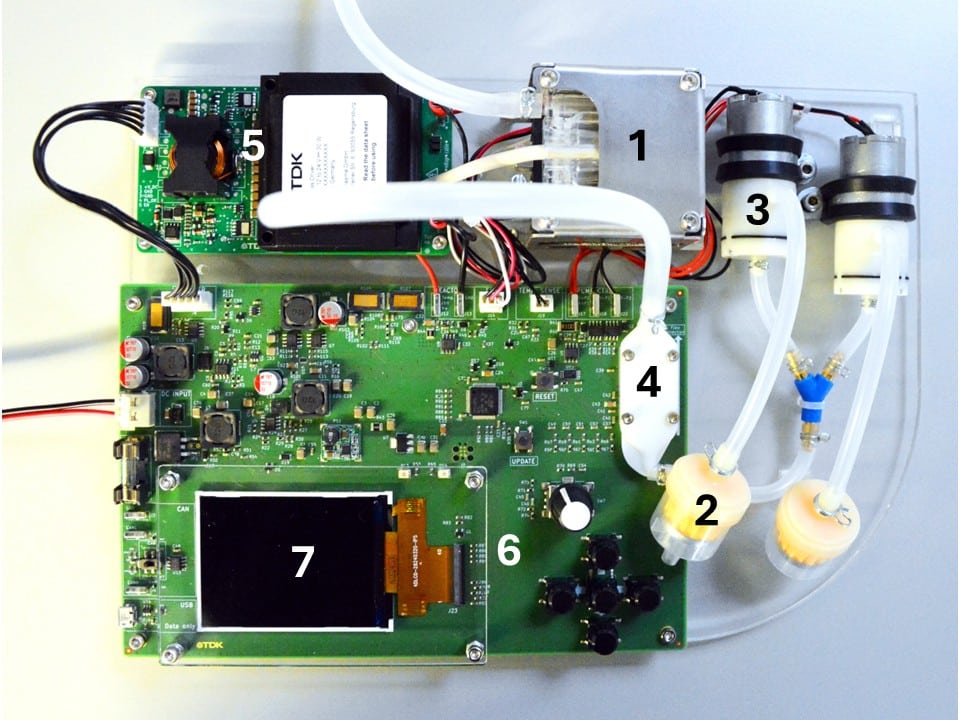

The heart of the MediPlas kit is the MediPlas reactor (1). In this reactor, a hybrid dielectric barrier discharge (HDBD) is ignited between a metal electrode and a dielectric barrier. The metal electrode is supplied by the DBD driver transformer via a high-voltage cable with a voltage between 2 and 6 kV in the frequency range 20 to 40 kHz. Gas is passed through the HDBD zone. The version of the MediPlas kit presented here uses the ambient air. This is drawn in from the environment through two dust filters (2) and fed to the MediPlas reactor by membrane pumps (3) connected in parallel. The power of the diaphragm pumps is controlled based on the value measured by the gas flow sensor (4) to reach the specified target gas flow.

The MediPlas reactor is equipped with a Peltier cooling module, powered via a cable from the board. The cooling power of the Peltier module can be adjusted individually. Depending on the operating mode of the DBD driver, the MediPlas reactor is supplied with continuous or intermittent power. Both the voltage of the DBD driver and the duty cycle of the intermittent operation (PWM, Pulse Width Modulation) can be adjusted. The DBD driver (5) supplies a PlasmaOK signal via the same connection, which can be used to diagnose the operating status of the gas discharge. This signal is derived from the current signal of the HDBD discharge using a high-pass filter that passes the signals in the megahertz range. These high-frequency signals are generated by the modulation of the ideal sinusoidal current signal by the micro-discharges of the HDBD. The PlasmaOK signal, a DC voltage in the range of hundreds of millivolts, is proportional to the power effectively coupled into the discharge chamber. If the PlasmaOK signal remains below a certain threshold, this means that no plasma is being generated.

The “brain” of the MediPlas kit is the electronic kit board (6) with a microcontroller and firmware stored in the memory chip. Thanks to a display (7), the DBD driver parameters (input voltage, frequency, and duty cycle of the PWM) can be set. Another adjustable electrical parameter is the Peltier module current, to determine the temperature of the gas discharge. In addition to the electrical parameters, the gas flow is also adjusted using a push button. The display also shows the most important actual values: PlasmaOK signal, Peltier power, and driver power. The MediPlas Kit board also enables communication with a PC via a USB interface.

Further technical details can be found in the MediPlas Datasheet, while the MediPlas User Guide provides a description of how to use the MediPlas Evaluation Kit.