Oxidation during plasma cleaning of metal – Publication in the April 2025 issue of the trade journal Galvanotechnik

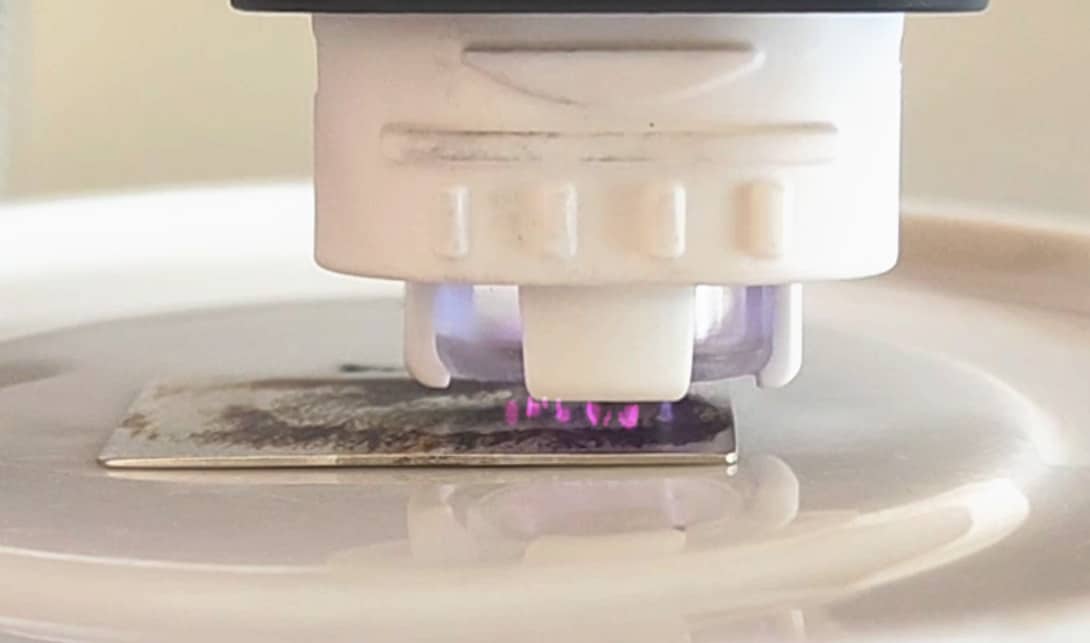

Pitch black instead of shiny silver – many metallic surfaces can oxidise undesirably when cleaned with an air-driven atmospheric plasma. Ways of cleaning easily oxidising surfaces with plasma without this effect are presented in detail in the technical article.

Atmospheric pressure plasma (ADP) is often used to remove organic residues – typically using an oxygen-containing plasma, for example air-based. For particularly demanding applications, the use of pure oxygen in DBD-based systems such as the MediPlas, can significantly increase the ozone concentration and therefore the cleaning performance.

In addition to cleaning, ADP treatment also increases the surface energy of metals, which improves their wettability and adhesion. However, what is measured here is usually not the pure metal surface, but the natural oxide layer – which only adheres weakly to metals such as copper or silver and can therefore be problematic.

In such cases, chemical reduction with hydrogen-containing gases, e.g. forming gas 95/5, is recommended. This method gently removes oxides and increases the surface energy at the same time. The reduction process can be accelerated by higher hydrogen concentrations or targeted temperature control – for example by adjusting the plasma parameters such as movement speed, nozzle distance or power.

However, the increased temperature during reduction harbours a challenge: it not only accelerates the reduction, but also the oxidation of the surface. As a result, a metal surface that has just been reduced can quickly oxidise again in the air. This can be remedied by creating a low-oxygen environment – for example by flushing the substrate with nitrogen while it is hot.