Integration plasmabrush into Aerosol Jet Printing System

Reference University of West Bohemia

Jiri Navratil – R&D Engineer for Aerosol Jet

Aerosol Jet systems print fine-feature electronic, structural and

Aerosol Jet is able to print nanomaterial inks in high resolution and

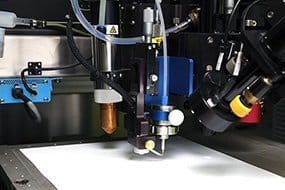

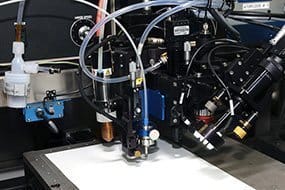

The plasma system is reliable and works as a substrate treating and cleaning device just before Aerosol Jet ink deposition. The plasma changes the surface energy of the substrate. This process leads to improved wettability of the substrates and so to better adhesion and quality of printed lines. The

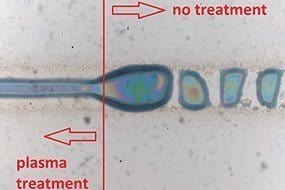

On picture 4 PEDOT (organically conductive material) was printed on PET film with the Aerosol Jet Printing System. The differences between the wettability before and after plasma treatment are clearly visible. This leads to a considerably better print quality.

Thanks to the full integration, the plasma treating can be immediately followed by Aerosol Jet printing. There is no need for manipulation with