Plasma activation of various plastics

Assessment of wettability, surface morphology and tensile strength of the adhesive bond with epoxy adhesive

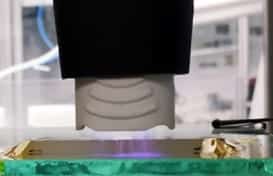

In the beta test phase Oliver Beier and Andreas Pfuch of INNOVENT e.V. Technologieentwicklung in Jena have investigated the plasma activation of various plastics after treatment with the piezobrush® PZ3 and the module “Standard”. They report in the case study about their expierences.

Different methods were used to analyze the plasma activation. For all three materials under investigation, polypropylene (PP), polycarbonate (PC) and polytetrafluoroethylene (PTFE), improved wettability was demonstrated already after one treatment at a speed of 20 mm/s. The method used here for was measuring the contact angle of water droplets. In the atomic force microscope (AFM) an increased roughness of the surfaces after treatment with the piezobrush® PZ3 was determined. The improved wettability and the nano roughening of the surface after treatment with piezobrush® PZ3 lead to a significant improvement in the adhesion of PP and PTFE. Adhesion tests of adhesive bonds with the epoxy adhesive DP460 from 3M on PP and PTFE showed a significant increase in tensile strength of the previously plasma activated samples compared to the untreated samples.

Assessing wettability with water contact measurements

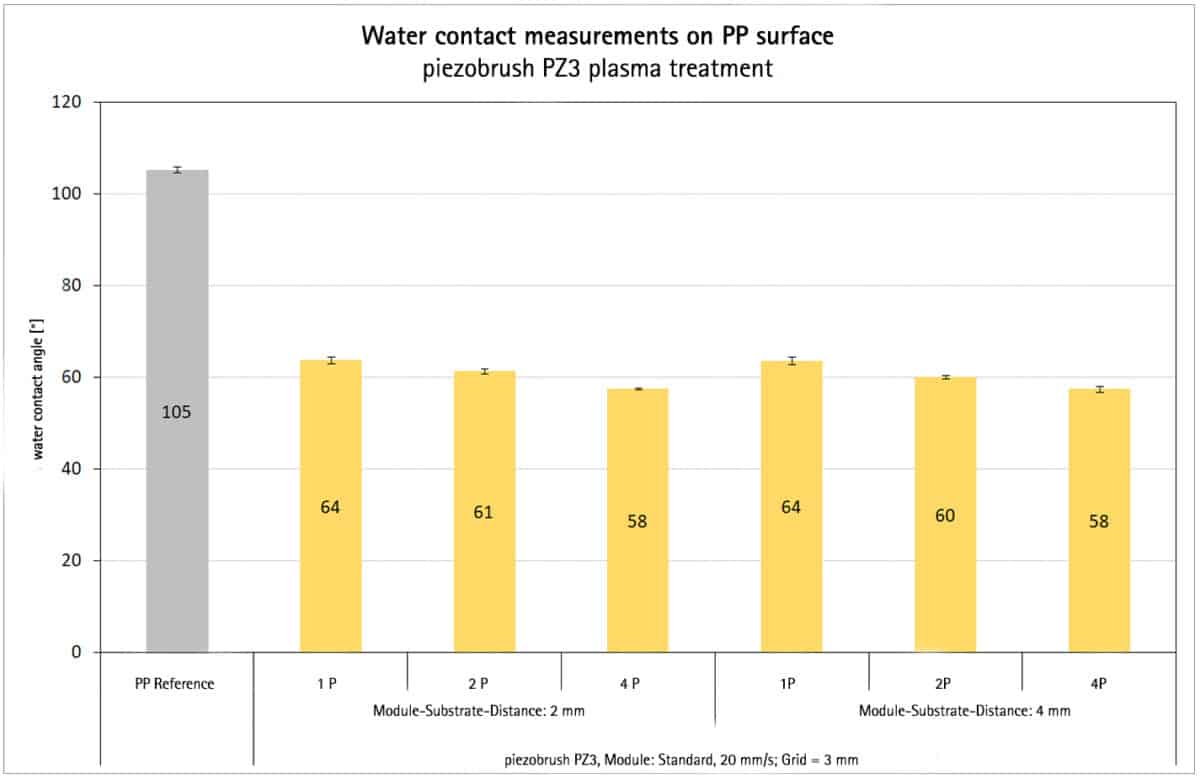

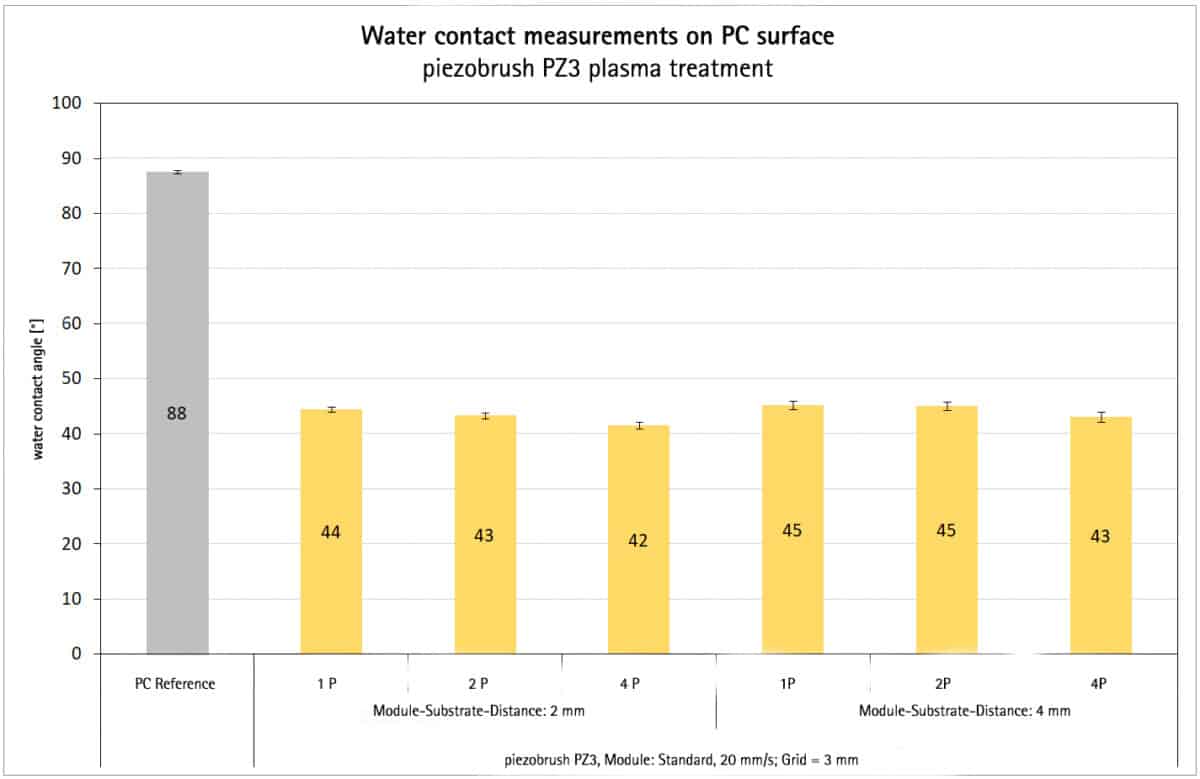

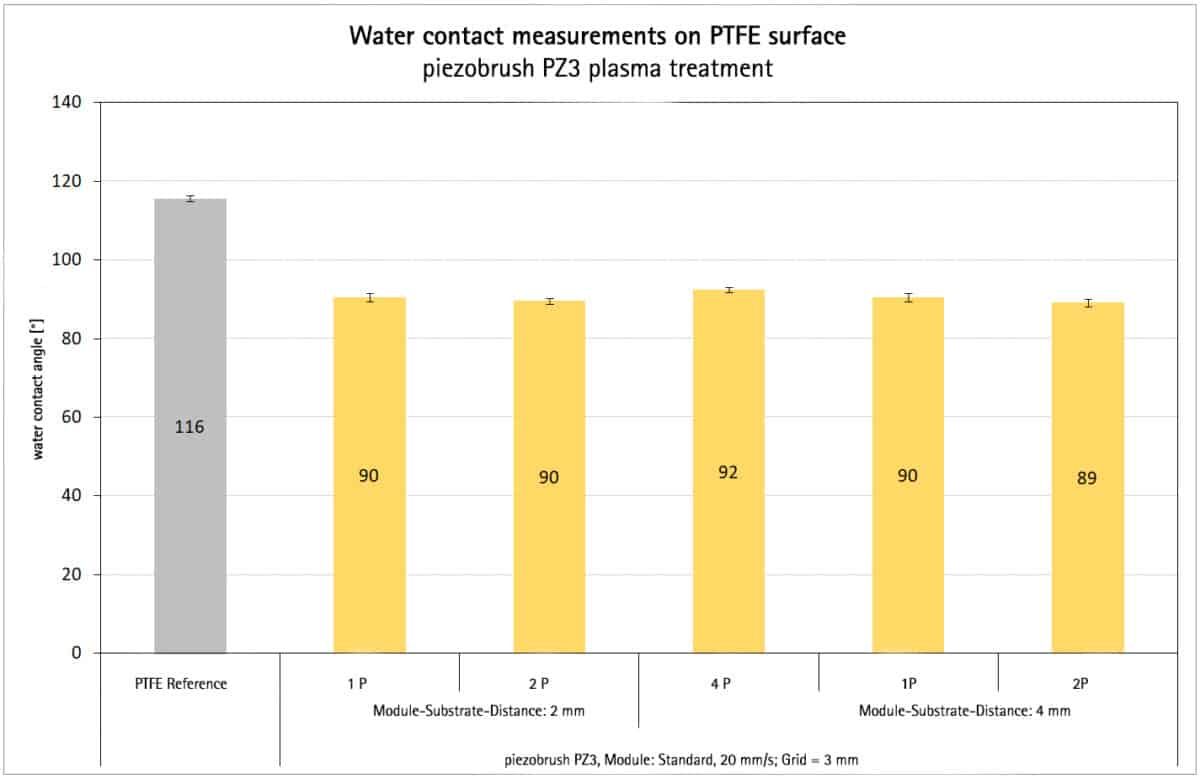

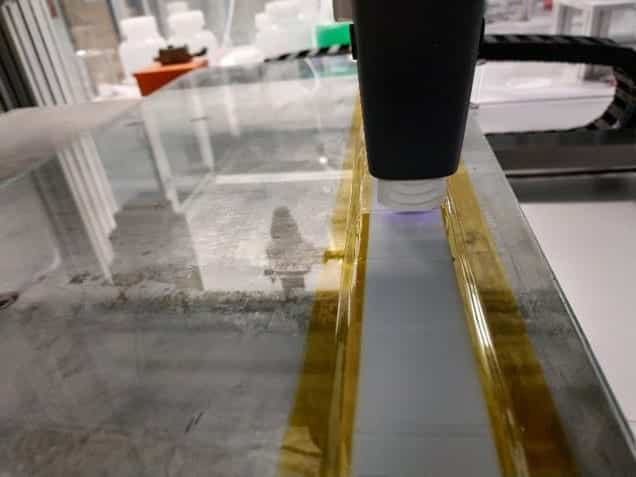

To evaluate the effect of plasma activation and its different parameter sets, 10 drops of distilled water with a volume of 1 µl are deposited on each sample. With the contact angle measuring instrument OCA 20 from DataPhysics GmbH their contact angles with the surface are determined. The lower the contact angle, the higher the wettability. A total of six different parameter sets were performed on all samples. Thereby the most important parameters are treatment speed, distance between plasma module and substrate and number of treatment passes (P). The speed is set to a constant 20 mm/s in all experiments by means of an automatic traversing unit. The treatment distances are selected to be 2 and 4 mm and for these one, two and four passes are tested with the piezobrush® PZ3. In all tests, the passes are scanned over the surface at a spacing of 3 mm.

Figures 1 to 3 show that the wettability on all three types of plastics is increased by treatment with the piezobrush® PZ3. Already one pass (1 P) achieves very good results, which can only be slightly improved by further passes (2 and 4 P).

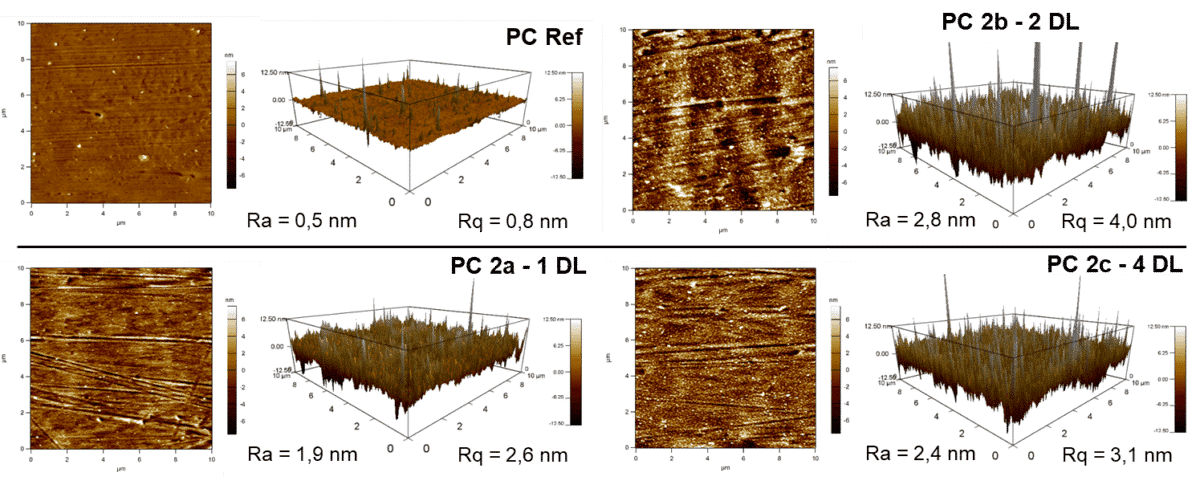

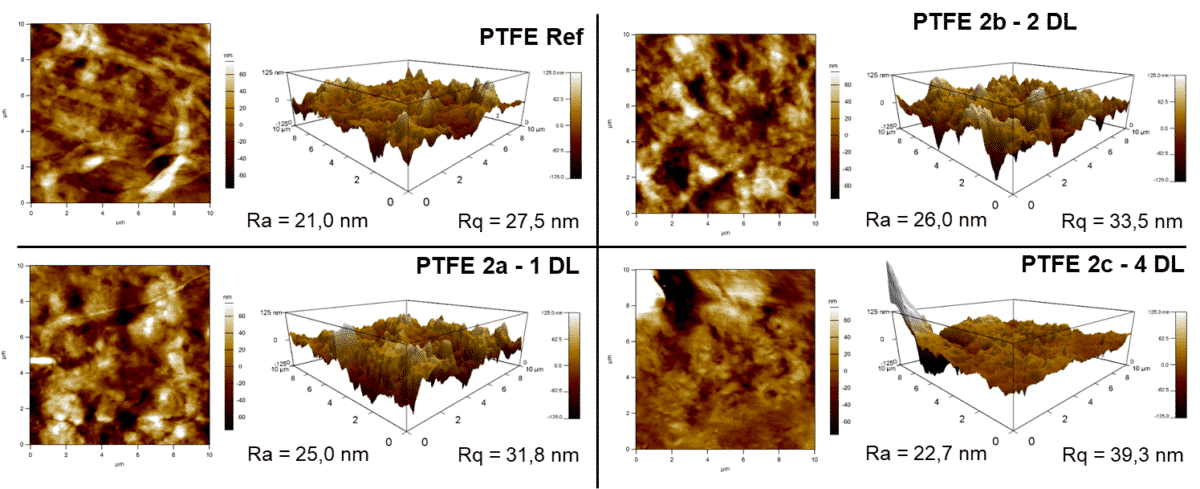

Measurement of surface roughness with the atomic force microscope

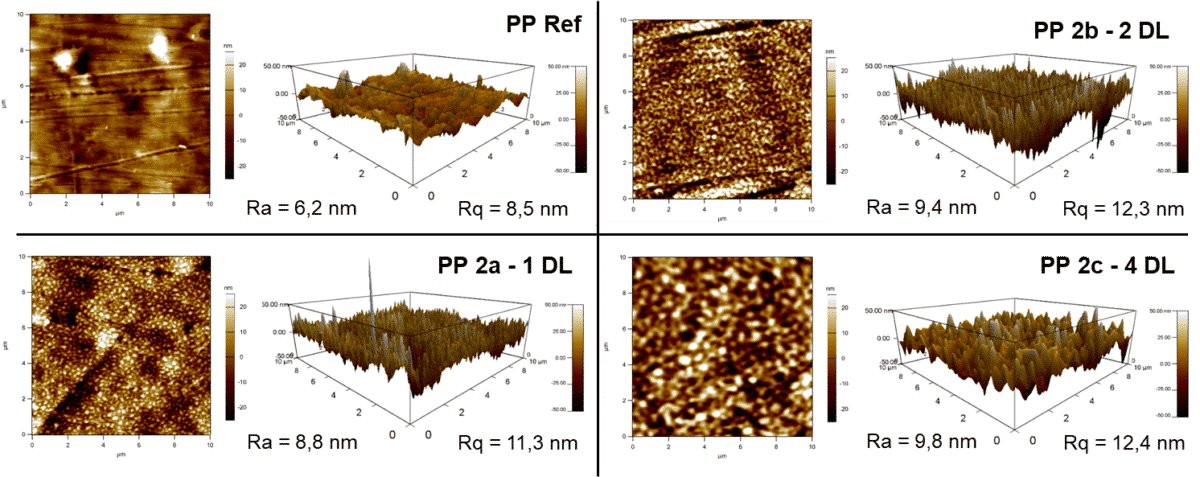

The analysis of the surface morphology also shows that just one pass with the piezobrush® PZ3 changes the plastic surfaces. In these tests, a distance of 4 mm between module and substrate is used at a speed of 20 mm/s. With the atomic force microscope MFP3D from Asylum Research, the reference samples as well as the samples treated with the piezobrush® PZ3 are measured and the roughness of the surfaces is determined. As the number of passes increases, the roughening in the nm range also increases, as can be seen in Figures 4 to 6.

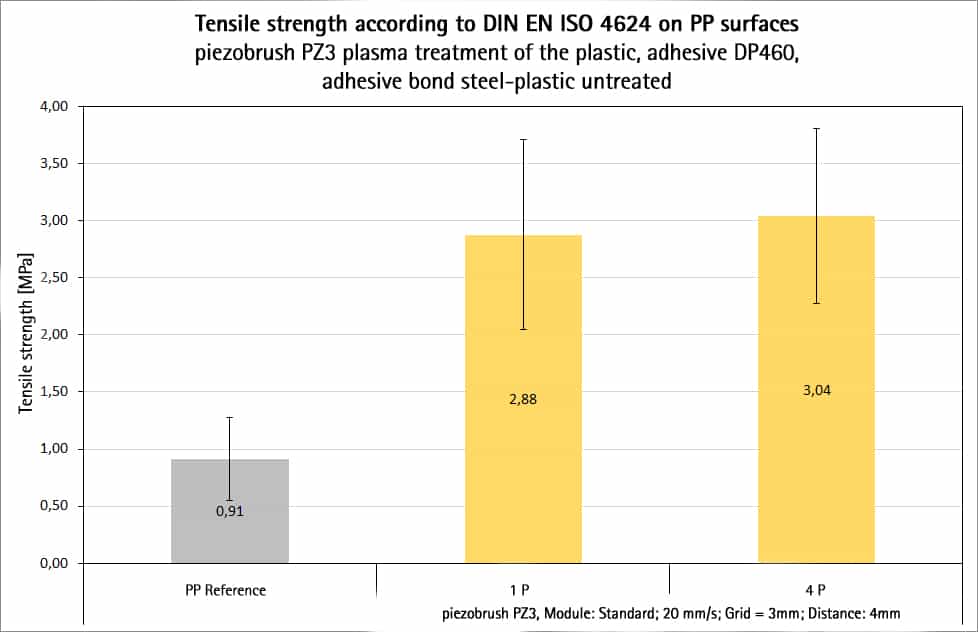

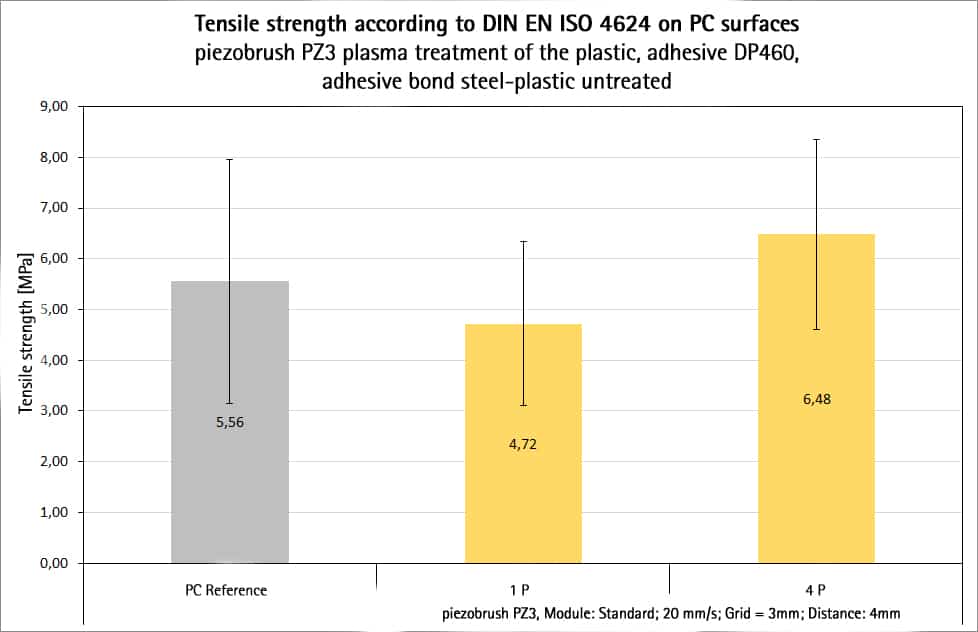

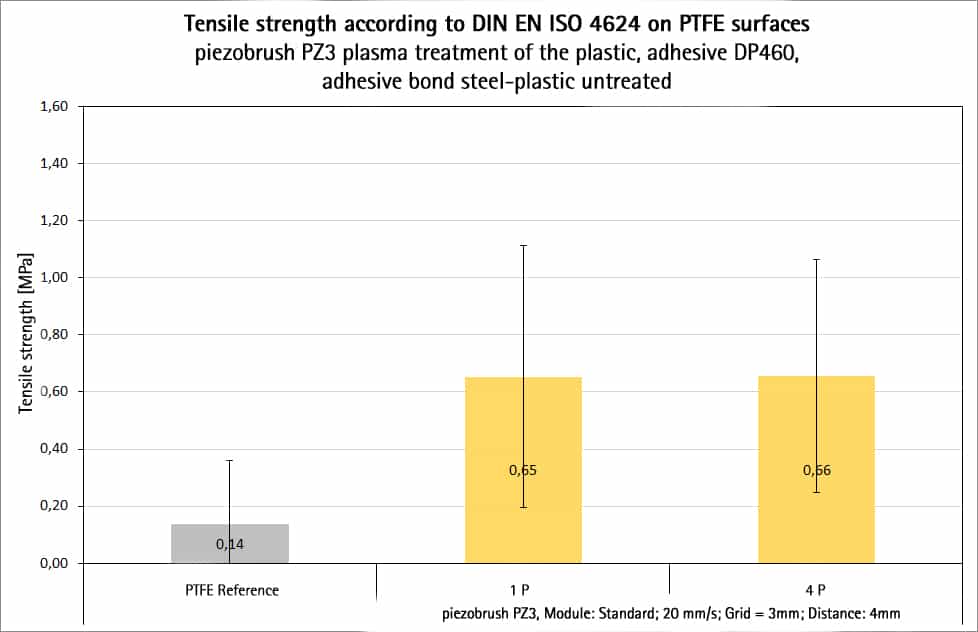

Adhesion tests of an adhesive bond between plastic and steel with epoxy adhesive

For the last series of tests with the most application-related aspects, the three plastics PP, PC and PTFE are joined with a steel die using 3M’s epoxy adhesive DP460. The adhesive bond is not stressed. After a curing time of 2 hours at 65°C, the tensile strength is determined according to DIN EN ISO 4624. For this purpose, 10 samples each are subjected to an adhesive tensile test with the test system Inspekt table 50 kN by Hegewald and Peschke. While the tensile strength of the plasma-treated samples is in the order of magnitude of the reference in the PC (see Fig. 8), a significant improvement of the adhesive bond is shown for both PP and PTFE, even after only one pass with the piezobrush® (see Fig. 7 and 9).

Summary of the results

Investigations of plasma activation of various plastics PP, PC and PTFE with the piezobrush® PZ3 show that even a single pass over the surfaces at a speed of 20 mm/s produces a significant and reproducible improvement in wettability. In addition, the surfaces are roughened in the nm range. In the final tests of the tensile strength of the adhesive bond with epoxy adhesive it becomes clear that both the improved wettability and the increased roughness are typically necessary but not always sufficient criteria for an improved bond. Although pre-treatment with piezobrush® PZ3 does not show any improvement in tensile strength for PC and the selected epoxy adhesive, it does show an improvement for the corresponding joints with PP and PTFE.

Overall, the beta testers from INNOVENT attest the piezobrush® PZ3 a clearly structured and intuitive program structure. Moreover switching between the two modules “Standard” and “Nearfield” is easy and safe. Last but not least there are good and homogeneous treatment results for the plasma parameters investigated.