How cold plasma functionalizes 3D-printed PCL scaffolds for tissue engineering.

The combination of additive manufacturing and plasma technology opens up new avenues in regenerative medicine and tissue engineering. A particularly innovative approach is the cold plasma surface modification of 3D-printed polycaprolactone (PCL) scaffolds, as is currently being researched at the Cabral Laboratory of the University of Otago (New Zealand).

3D-printed PCL scaffolds in tissue engineering

Polycaprolactone (PCL) is a biodegradable, thermoplastic polyester that is ideally suited for tissue engineering applications due to its mechanical stability, thermoplastic processability and biocompatibility. Melt extrusion can be used to produce 3D scaffolds that serve as temporary support structures for cells and enable the growth of new tissue.

However, a central problem of PCL is its hydrophobic surface, which can limit cell adhesion and proliferation. This is exactly where plasma surface treatment comes in.

Cold plasma as the key to improved cell adhesion

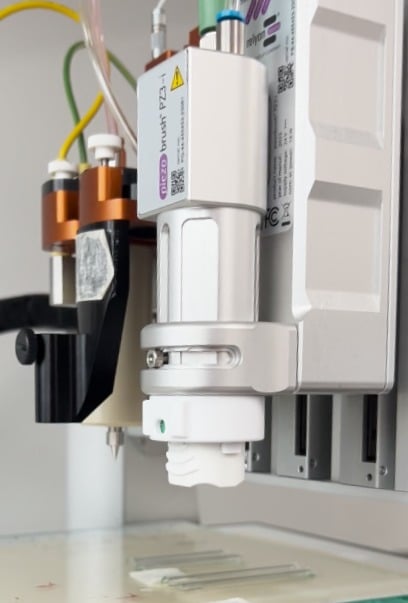

In order to specifically improve the biological functionality of the PCL scaffolds, they are subjected to cold plasma surface modification. The PiezoBrush PZ3-i from relyon plasma is used for this purpose, which is integrated directly into the robot system of the GeSiM BioScaffolder 3.1. The atmospheric cold plasma activates the material surface. The introduction of polar functional groups increases surface energy. This leads to a significant improvement in cell adhesion and allows the cells to bind better to the surface. This process creates the decisive factors for demanding applications in tissue engineering and regenerative research.

Research at the University of Otago – the Cabral Laboratory

The work is being carried out under the direction of Associate Professor Dr. Jaydee Cabral (PhD, MRSNZ). The scientific focus of the Cabral laboratory is on the development of innovative biomaterials, tissue engineering and regenerative medicine.

Unique biofabrication platform in New Zealand

The Cabral laboratory has outstanding technological equipment: it houses the GeSiM BioScaffolder 3.1. This 4-axis, modular 3D bioprinting system combines several key technologies in one platform:

- Melt Electrowriting

- Coaxial 3D Bioprinting

- Piezoelectric technology

- Integrated cold plasma surface modification (relyon plasma PiezoBrush PZ3-i)

This combination enables the production of tailor-made, functionalized 3D scaffolds in a continuous process and opens up new possibilities for the development of complex, biologically active structures.

Conclusion

The work of the University of Otago impressively shows how interdisciplinary technologies – in particular the combination of 3D bioprinting and relyon plasma cold plasma technology – enable the next generation of biomedical implants and functional tissue constructs and make a targeted contribution to improving cell-material interaction.