Functionalization and disinfection of implants

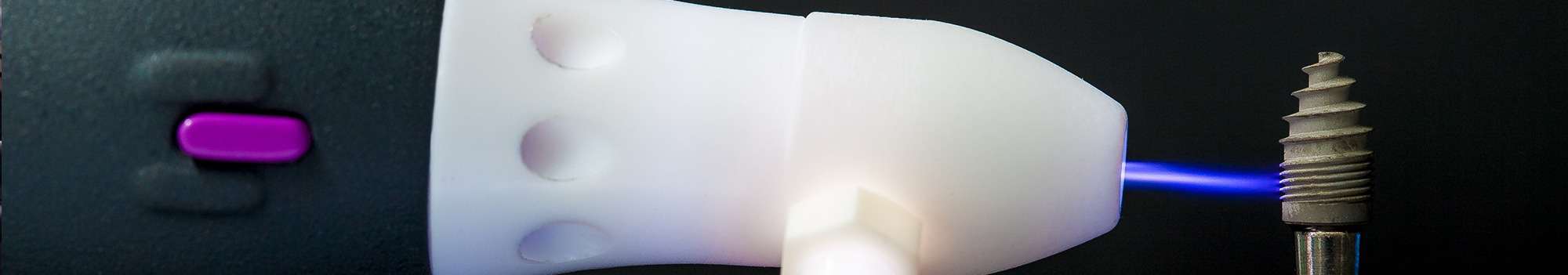

piezobrush® PZ2 – portable plasma device

The professional journal Plastverarbeiter has published an article about plasma functionalization and disinfection of implants with the piezobrush® PZ2.

When it comes to manufacturing implants, for example for dental applications, more and more manufacturers are turning to the high-performance plastic PEEK (polyetheretherketone). Plasma functionalization of the PEEK implant directly before insertion optimizes the conditions for binding to the organic tissue and thus the healing process.

relyon plasma piezobrush® PZ2

Biocompatibility and stability, the good sterilization resistance of the polymer and its X-ray transparency make PEEK a frequently used material in implantology. Compared to titanium or ceramics, for example, the material has a lower modulus of elasticity or higher elasticity. The values are in the order of magnitude of the natural bone material. This prevents a typical problem – the stress-shielding effect: Due to the high stiffness of the metals and ceramics, the implant takes over a large part of the mechanical load. The bone is thus relieved and can regress over time. Another advantage of PEEK is that dental implants can be produced more cheaply by injection molding. Plastic implants have so far been inferior in terms of the healing process in which the bone cells grow onto the implant.

A functionalization of the surfaces by an atmospheric pressure plasma can improve the conditions here. The effect is based on two positive effects of the plasma: On the one hand, any microorganisms that may be present on the surface are destroyed, which contributes to a reduced risk of infection. At the same time, the “finely cleaned” surface increases the body’s tolerance to the foreign body implant. The second effect is based on the increase of the surface energy of the plastic – up to the so-called water wettability. As a result, the surface of the implant can be better wetted by the body’s own substances such as blood and other fluids, which promotes and accelerates the healing process.

A wear-free plasma source piezobrush® PZ2 was developed for the plasma functionalization of the implant surface. It is integrated into a small, lightweight and portable handheld device and operates under atmospheric pressure without external process gas. The plasma is ignited by a multilayer piezo element with atmospheric oxygen and is characterized by a high activation efficiency. Since the plasma generated is particle-free, functionalization can take place directly before the implant is inserted in the operating area or at the treatment chair. The functionalization process of the implant takes place at a low temperature of around 45°C. Therefore, the treatment with the piezobrush® PZ2 does not lead to any thermal stress on the plastic or impairment of the dimensional accuracy of the implant. The design of the light-weight handheld device allows both use by technically less experienced persons and safe handling for both user and patient. The low supply voltage of 12 volts also contributes to this.

Professional article, © Plastverarbeiter 2015