Plasma surface functionalization prior to the structural bonding of plastics

This article deals with the surface functionalization with plasma prior to the structural bonding of plastics.

Plastics are usually characterized by inert surfaces with surface energies between 20 and 40 mN/m. In order to wet a surface, however, the surface energy of the polymer must exceed the one of the paint or the adhesive. This condition can be achieved through a plasma treatment of the surface and is called “activation“ in plasma technology.

More important than the improved wetting are chemical groups newly incorporated into the surface. This so-called surface functionalisation creates additional chemical “bonding anchors“ for the paint or the adhesive.

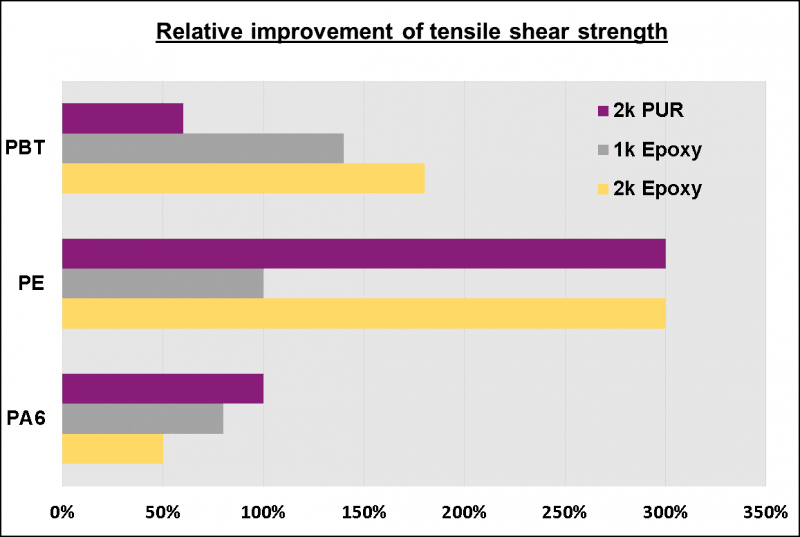

The relative improvement bond is shown in the following diagram for various plastics and adhesives based on the increase of shear force until bond rupture. Depending on the substrate and adhesive, it is possible to achieve shear strengths of up to 50 MPa through an optimized treatment with the PB3/PS2000 system from relyon plasma GmbH.

Fig. 1: Relative increase of the shear strength after a short plasma treatment with dry compressed air at atmospheric pressure for the various technical thermoplastic materials: PBT (polybutylene terephthalate), PE (polyethylene, HDPE) and PA6 (polyamide). 100% corresponds to a doubling of the shear strength compared to the untreated surface.

Comparable effects are found on polypropylene (PP) and LCP polyester (LCP). It is important that the process parameters gas flow, processing distance and the injected electrical power are adapted to the desired processing speed and material. A typical starting point that always achieves a significant improvement of the bond quality is at approx. 200m/s working speed with a working distance of approx. 12 mm and the use of the relyon plasma nozzle A450 with 50L/min air.

Composite design: carbon fiber reinforced plastic

Users of adhesives increasingly have to bond plastics and metals together. A typical example is the bonding between carbon fiber reinforced plastic and aluminum materials in the automotive sector. PU adhesives can meet the requirements of the bonds. However, a polymer matrix of carbon fiber reinforced materials has poor bonding characteristics. In this case, the atmospheric plasma treatment can be simply integrated into each series process.

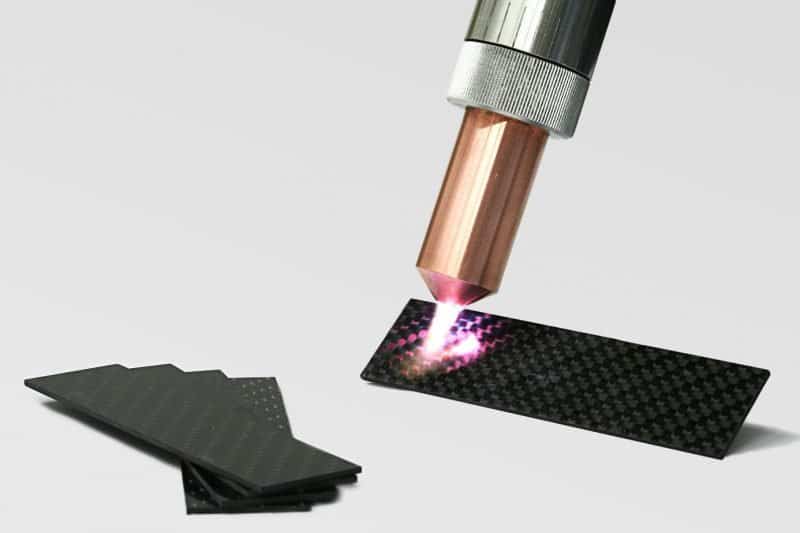

Figure 2: plasmabrush PB3 plasma jet directed on a carbon fiber reinforced plastic specimen (25mm x 80mm).

When atmospheric-pressure plasma processes are used with air, then mainly oxygen and hydroxyl groups are placed on the plastic surface. These groups can form covalent bonds with the PU glue. The oxygen percentage close to the surface can increase by a factor of 3 achieving shear strengths above 20 MPa. In case of a PA6 matrix this will quadruple the strength. This shear strength can still be demonstrated even after several weeks.

If instead of compressed air, other process gases are used such as nitrogen or forming gas (N2/H2) it is possible to generate other specific groups on the surface.

More information about the structural bonding of plastics:

Contact us >>