Application of the plasma bridge for grounding of conductive substrates

Autoren: Dariusz Korzec, Markus Hoffmann and Stefan Nettesheim

Datue: March 2023

Abstract

An atmospheric pressure plasma jet (APPJ) sustained by a pulsed atmospheric arc (PAA) transferred on an electrically conducting surface was operated with a mean power of 700 W, a pulse frequency of 60 kHz, and a gas mixture of N2 and H2 with up to 10% H2, flowing at 30 to 70 SLM. The plasmabrush® PB3 was used for this purpose. It was shown that the plasma bridge ignited between the grounded injector and electrically conducting and floating substrates can be used for electrical grounding. This allowed for arc transfer on such substrates.

The plasma bridge was stable for Argon flow through the injector from 3 to 10 SLM. Its length was between 5 and 15 mm. The plasma bridge current was 350 mA. The copper contact pads on an alumina electronic board were treated using the plasma bridge sustained by Ar injection for grounding. First, an oxide film of about 65 nm was grown by a compressed dry air (CDA) plasma jet. Then, this film was reduced at a speed of 4 cm2/s by forming gas 95/5 (95% of N2 and 5% of H2) plasma jet.

Introduction

The atmospheric pressure plasma jet (APPJ) in its numerous variations is a kind of cold atmospheric plasma (CAP) or atmospheric pressure plasma (APP) broadly used in research and industry. The low-temperature arc jet has a high potential for material processing due to its high local plasma density. The popular way of arc stabilization in low-temperature arc jets is a gas vortex. The physical, electrical, and material properties of such jets have been investigated. Many applications have been described, e.g., the modification of the surface of polymers for the improvement of adhesion, for example polyethylene, glass-fiber-reinforced polypropylene, or polydimethylsiloxane (PDMS). Furthermore, metal surfaces can be treated. Surface modification for the hydrophilic property of stainless steel treated by an atmospheric pressure N2-O2 plasma jet was demonstrated. Varnished or polymer-coated metal surfaces can also be successfully treated. A material increasingly interesting for surface treatment is glass. Other applications are oxidation and rapid annealing.

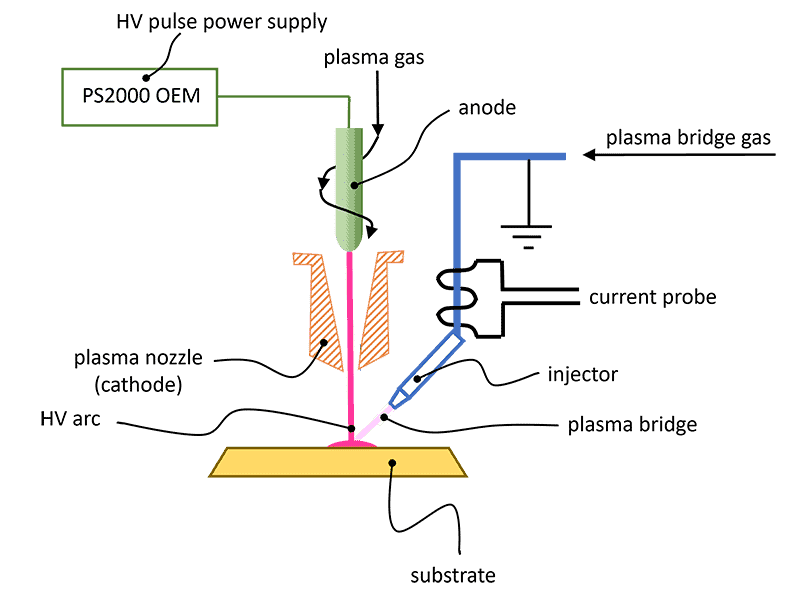

The plasma generator used in this study belongs to the pulsed atmospheric arc plasma jets (PAA-PJs). Its discriminating feature is the generation of the arc via HV pulses in the kHz range with voltages up to 15 kV for ignition and in the range of 500 V to 3000 V for sustaining the plasma. Recently, its physics was investigated by laser scattering techniques and optical spectroscopy. The influence of the pulse amplitude and frequency on PAA-PJ’s properties was examined.

Diffuse plasma mode

The PAA-PJ can be operated in diffuse or focused plasma mode. The broadest application of diffuse mode is the activation of different surfaces to increase the surface free energy (SFE) of polymers for the improvement of the paintability or gluing properties or for casting. The enhancement of the bonding properties of pressure-sensitive adhesives on coatings of white goods by means of atmospheric pressure plasma treatment has been demonstrated. Another example is the surface modification of carbon fibers. A strong increase of wetting, expressed as a decrease of the contact angle, resulting in the widening of printed electric contacts was observed after nitrogen plasma treatment of gas, PI, and

PET before aerosol jet printing. The improvement of the mechanical shear strength of glued joints on PAA-PJ-treated aerosol-jet-printed pads has been documented. The suitability of the PAA-PJ for bacteria inactivation on temperature-sensitive surfaces was demonstrated on an example of geobacillus stearothermophilus spores.

The high energy density in the arc zone allows for the use of the PAA-PJ for coating processes. A 1.29 nm/s deposition rate of zinc oxide was demonstrated using a nebulized ZnCl2 solution sprayed into the downstream of the nitrogen plasma jet. The PAA-PJ can be used for low-density polyethylene coating, fluxing of printed circuit boards, coating wood with polyester or TiO2, and coating of bismuth oxide circular droplets.

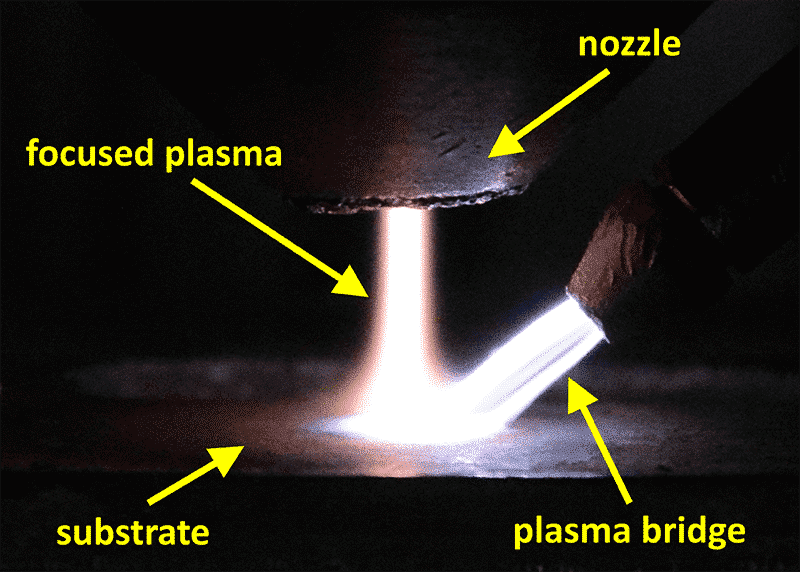

Focused plasma mode

The term focused plasma mode is used for the operation of the PAA-PJ with the HV arc transferred from the grounded nozzle to a grounded, electrically conducting substrate. Under such conditions, a dense plasma is produced directly at the substrate surface. The transferred arc has been proven to be efficient for the cleaning, delubrication, oxide reduction, surface roughening, or depainting of metal surfaces. The mechanism of adhesion improvement is mainly chemical, but also, an increase in the surface roughness is involved. An additional advantage of the transferred arc is that no erosion of the nozzle occurs, and consequently, the lifetime of the nozzle can be prolonged by an order of magnitude. The applicability of this operation mode is limited by the need for the connection of the substrate to the electrical ground which is not always possible.

This study showed how an electrically floating surface charged up by a transferred arc can be grounded using a plasma bridge. Originally, the term plasma bridge referred to the low-pressure plasma used for

the neutralization of an ion beam. However, in this study, it means the gaseous discharge ignited at atmospheric pressure in a gas with a low breakdown voltage such as argon for establishing a highly conductive electric connection between the substrate and the grounded gas injector. In this paper, the basic properties of such a plasma bridge are discussed. The reduction of oxidized copper contact pads distributed on a ceramic plate demonstrated the technological applicability of such a plasma bridge.

Conclusion on grounding of conductive substrates

If the PAA-PJ is used for the treatment of electrically conducting substrates, the transferred arc can be established only to electrically grounded surfaces. In some cases, the conducting surfaces, e.g., contacting pads of electronic boards, are constructed as electrically floating. In this study, it was shown that, for the grounding of floating electrodes, the plasma bridge ignited in argon can be used. The plasma bridge can be achieved by flooding of the contact pad by argon from an electrically conducting and grounded injector tube. The plasma bridge was ignited because, without grounding, the potential of the electrically

floating substrate rose to many hundreds of volts, sufficient for gaseous breakdown in argon between the substrate and the injector. After ignition, the plasma bridge can be sustained even without the substrate between the injector and the HV arc.

The establishment of the plasma bridge was possible for argon flows between 3 and 10 SLM. The plasma bridge cannot be sustained for an argon flow below 3 SLM. At such low flows, the argon flux did not expand sufficiently to reach the substrate and allowed closing the electric gap between the biased substrate and the injector. The plasma bridge cannot be sustained for an argon flow over 10 SLM. The possible reason is the transition of the argon flow from laminar to turbulent, resulting in disruption of the argon bridge discharge.

Application example

The reduction of oxidized copper contact pads on alumina plates by forming gas 95/5 plasma was investigated as an application example. To achieve the grounding of the contact pads, the argon plasma bridge was used. The contact pads on the electronic board were made free from oxides without damage on the electrodes or on the solder stopping paint. Despite the non-conducting gaps between the contact pads, the plasma bridge was not extinguished during the entire duration of the electronic board treatment. The cuprous oxide film with a thickness of about 66 nm on an electric board with an area of 210 cm2 could be reduced within a 2 min process, reaching the processing speed of 4 cm2/s. For the typically much thinner native oxide, the process speed could be increased on order of magnitude.

Read and download technical paper