ISGATEC yearbook 2025

Cold atmospheric pressure plasmas (ADP) are widely used for the conditioning of polymer surfaces; prolonged interaction leads to changes in material properties in the form of erosion.

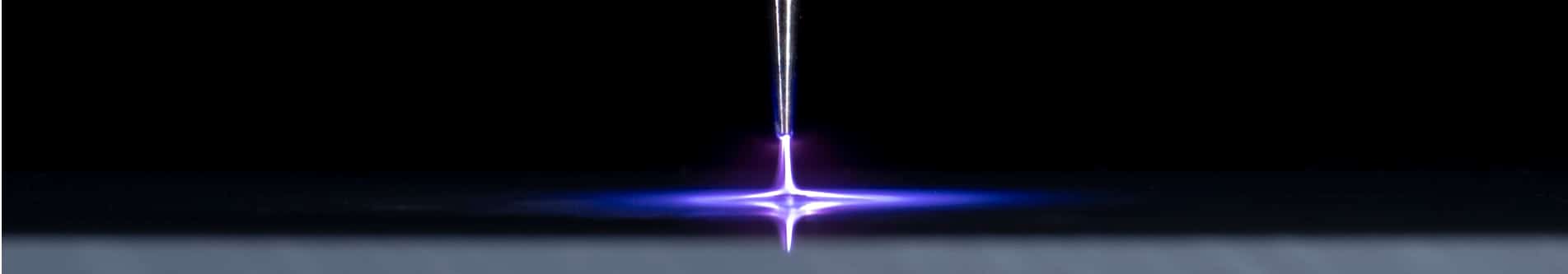

Our plasma systems are very well suited for the surface treatment of polymers (plastics). The aim of the treatment is plasma activation and plasma cleaning in order to prepare polymers for subsequent processes such as printing, painting or gluing.

Polymers such as polypropylene or polyethylene often have a low surface energy. This leads to adhesion problems during printing, so that the printed ink can easily be rubbed off or that the ink does not adhere to the surface at all. To counteract this, polymers are treated with plasma. As far as temperature-sensitive materials are concerned, they can be treated with cold atmospheric pressure plasma, as no temperature entry affects the material. Surface treatment of polymers is so very important for better adhesion of inks.

Key Word Search