Surface activation of low energy surfaces

The paper deals with the surface activation of low energy surfaces. It shows how surfaces of plastics such as polypropylene, PTFE or silicone can be effectively treated with cold atmospheric pressure plasma to achieve good wettability and thus optimize the adhesive strength of an acrylate-based adhesive.

Introduction

On the one hand, low-energy surfaces have the positive property of repelling dirt and allowing water to roll off. However, these plastics are typically very difficult to print or glue.

All surfaces have a characteristic polarity and surface tension. The surface energy is an important basis for the selection of the appropriate adhesive. Besides roughness and cleanness, the surface energy determines the maximum achievable adhesive strength of the adhesive. As a basic rule can be stated: The surface energy of the adhesive needs to be lower than the one of the materials to be bonded (substrate). Acrylate-based adhesives are polar and therefore have relatively high surface energy. Acrylate-based adhesives achieve an ideal final adhesion on polar substrates (e.g. glass or metals) with a high surface energy.

More critical is the use of acrylate-based adhesives for materials with low surface energy (non-polar substrates) such as silicone, PTFE and polypropylene. Easier than using a new adhesive formulation for each substrate would be to raise the surface to a sufficient level of surface energy, e.g. with an atmospheric plasma treatment.

Materials and methods

Three very widely used low-energy polymers were selected for the experiments:

- Polytetrafluorethylene (PTFE) with 19 mN/m

- Silicone with 26 mN/m

- Polypropylene (PP) with 31 mN/m

A simple hand-held cold plasma system piezobrush® PZ2 has been used for cold surface treatment. For comparison, a treatment of the surface with a typical atmospheric pulsed plasma jet plasmabrush® PB3 was also investigated. Air and forming gas (N2:H2 = 95:5) was used as process gas.

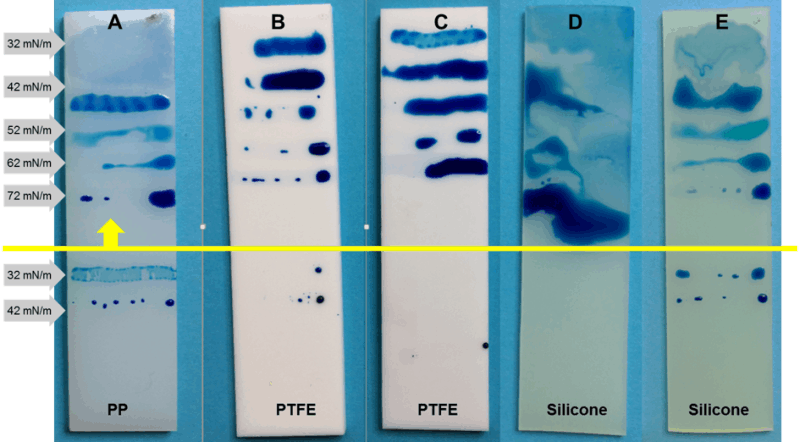

A first indication of the surface energy can be obtained with test inks which are applied to the sample. The samples were each exposed up to half of the plasma process. Figure 1 shows a significant increase in surface energy for all samples.

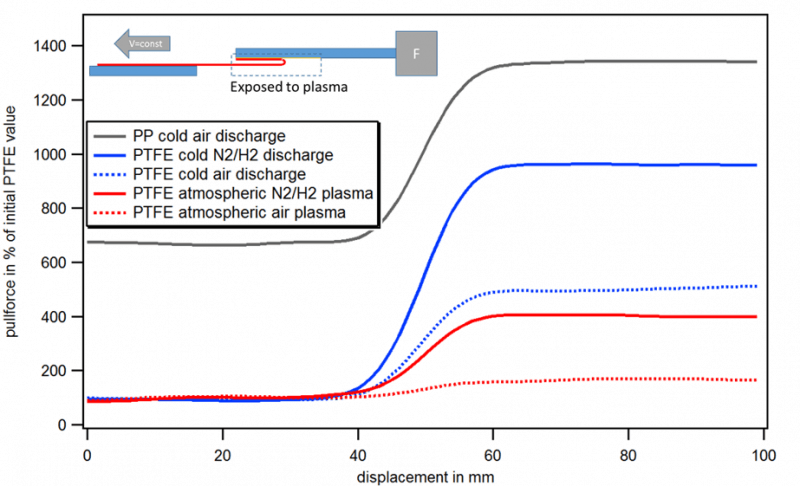

Adhesive forces were measured in a peel test with a tractor at a defined pull-off speed. During the tensile test, the adhesive tape first peels off the untreated and afterwards of the plasma treated surface. In all tensile tests a sudden increase in adhesion is observed, which correlates on the sample with the transition from the untreated (low-energy) to the treated (high-energy) surface.

Polypropylene, a widely used thermoplastic polymer, is physiologically harmless and biologically inert and therefore very suitable for applications in food and pharmaceutical industries. Because of its low surface energy, polypropylene is difficult to print or bond. Therefore, the treatment of the surface, e.g. with corona systems, on an industrial scale is applied. [1,2,3,4].

For polypropylene, a surface energy of approx. 58 mN/m is achieved with cold treatment using piezobrush® PZ2 starting at 31 mN/m after a short treatment period. The peel test results in a doubling of the adhesion for an acrylate-based adhesive tape.

Silicone elastomers are used in various areas due to their excellent mechanical properties, their resistance to UV light and their chemical resistance even at elevated temperatures. The disadvantage of silicone elastomers is the problematic bonding with other materials due to the low surface energy.

The effect caused by the cold discharge of the piezobrush® PZ2 with forming gas is only slightly more significant than that of using air. In both cases, complete water wettability is achieved.

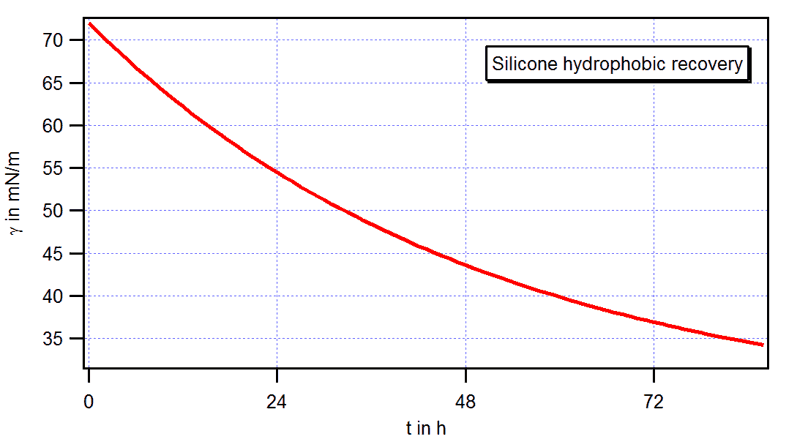

It is a known fact that silicones with hydrophilic surface properties can be obtained by plasma treatment, but this effect is not permanent over a long period of time. [5,6,7,8].

PTFE is very inert. Its chemical resistance ensures a long service life and good compatibility in the medical technology sector. PTFE is one of the few plastics that can be steam sterilized in an autoclave at 130 °C, but it is difficult to wet and very difficult to bond. The contact angle with water is 126°. It is known that under certain conditions PTFE can be treated with plasma to increase the surface energy. [9,10,11,12].

Summary

All investigated low energy plastic surfaces (polypropylene, silicone and Teflon) can be activated very well with the cold discharge of the piezobrush® PZ2 and show a significant increase of the surface energy. For PTFE, forming gas (nitrogen/hydrogen) is far more effective than air.

Literature

- Martina Lindner, Norbert Rodler, Marius Jesdinszki, Markus Schmid, and Sven Sangerlaub. Surface energy of corona treated PP, PE and PET films, its alteration as function of storage time and the effect of various corona dosages on their bond strength after lamination. Journal of Applied Polymer Science, 135(11):45842, 2018.

- Igor Novák and Ivan Chodák. Adhesion of poly(propylene) modified by corona discharge. Die Angewandte Makromolekulare Chemie, 260:47-51, 1998.

- J. Skalný, M. Luknáarová, and D. Dindošová. AC corona – discharge treatment of polypropylene foils effects of gaseous atmosphere. Czech. J. Phys B, B38:329-337, 1988.

- Mark Strobel, Viv Jones, Christopher S. Lyons, Michael Ulsh, Mark J. Kushner, Rajesh Dorai, and Melvyn C. Branch. A comparison of corona-treated and flame-treated polypropylene films. Plasmas and Polymers, 8:61-95, 2003.

- Emmanuel P. Everaert, Henny C. Van Der Mei, Joop De Vries, and Henk J. Busscher. Hydrophobic recovery of repeatedly plasma-treated silicone rubber. part 1. Storage in air. Journal of Adhesion Science and Technology, 9(9):1263-1278, 1995.

- Jongsoo Kim, Manoj K. Chaudhury, Michael J. Owen, and Tor Orbeck. The mechanisms of hydrophobic recovery of polydimethylsiloxane elastomers exposed to partial electrical discharges. Journal of Colloid and Interface Science, 244:200-207, 2001.

- Jongsoo Kim, Manoj K. Chaudhury, and Michael J. Owen. Modeling hydrophobic recovery and electrically discharged polydimethylsiloxane elastomers. Journal of Colloid and Interface Science, 293:364-375, 2006.

- Elidiane C. Rangel, Giovana Z. Gadioli, and Nilson C. Cruz. Investigations on the stability of plasma modified silicon surfaces. Plasma and Polymers, 9(1):35-48, 2004.

- P. Favia, A. Milella, L. Iacobelli, and Riccardo d’Agostino. Plasma Pretreatments and Treatments on Polytetrauoroethylene for Reducing the Hydrophobic Recovery, chapter 20, pages 271-280. John Wiley & Sons, Ltd, 2005.

- Shinya Ishikawa, Ken Yukimura, Koichi Matsunaga, and Toshiro Maruyama. Surface modification of poly(tetrauoroethylene) film using dielectric barrier discharge of intermittent pulse voltage. Japanese Journal of Applied Physics, 39(9R):5223-5228, 2000.

- Ulla König, Mirko Nitschke, Anke Menning, Grit Eberth, Matin Pilz, Christine Arnhold, Frank Simon, Gudrun Adams, and Carsten Werner. Durable surface modification of poly(tetrauoroethylene) by low pressure H2O plasma treatment followed by acrylic acid graft polymerization. Colloids and Surfaces B: Biointerfaces, 24(1):63- 71, 2002.

- Akira Takeuchi, Takahiro Kurahashi, and Kyosuke Takeda. Effect of microwave plasma surface treatment for improved adhesion strength of direct copper plating on polytetrauoroethylene (PTFE). In Conference Proceedings of IPC APEX EXPO, pages 1-7, April 2009.