Plasma technology for durable joints

Professional article: Mikroproduktion

Published: June 2019 – Mikroproduktion

Author: Corinna Little

Atmospheric pressure plasma technology can be used in a variety of ways to achieve good adhesion and improve bondings. This makes the process an attractive alternative to chemical bonding agents and solvents for durable joints

The quality of components and systems depends decisively on the connections of the individual components. If the quality is not satisfactory, this has undesirable consequences, ranging from adhesion breaks in adhesive bonds to the failure of sealing beads and flaking varnish. The bonding partners often interact in different aggregate states, often involving a liquid bonding partner and a solid surface.

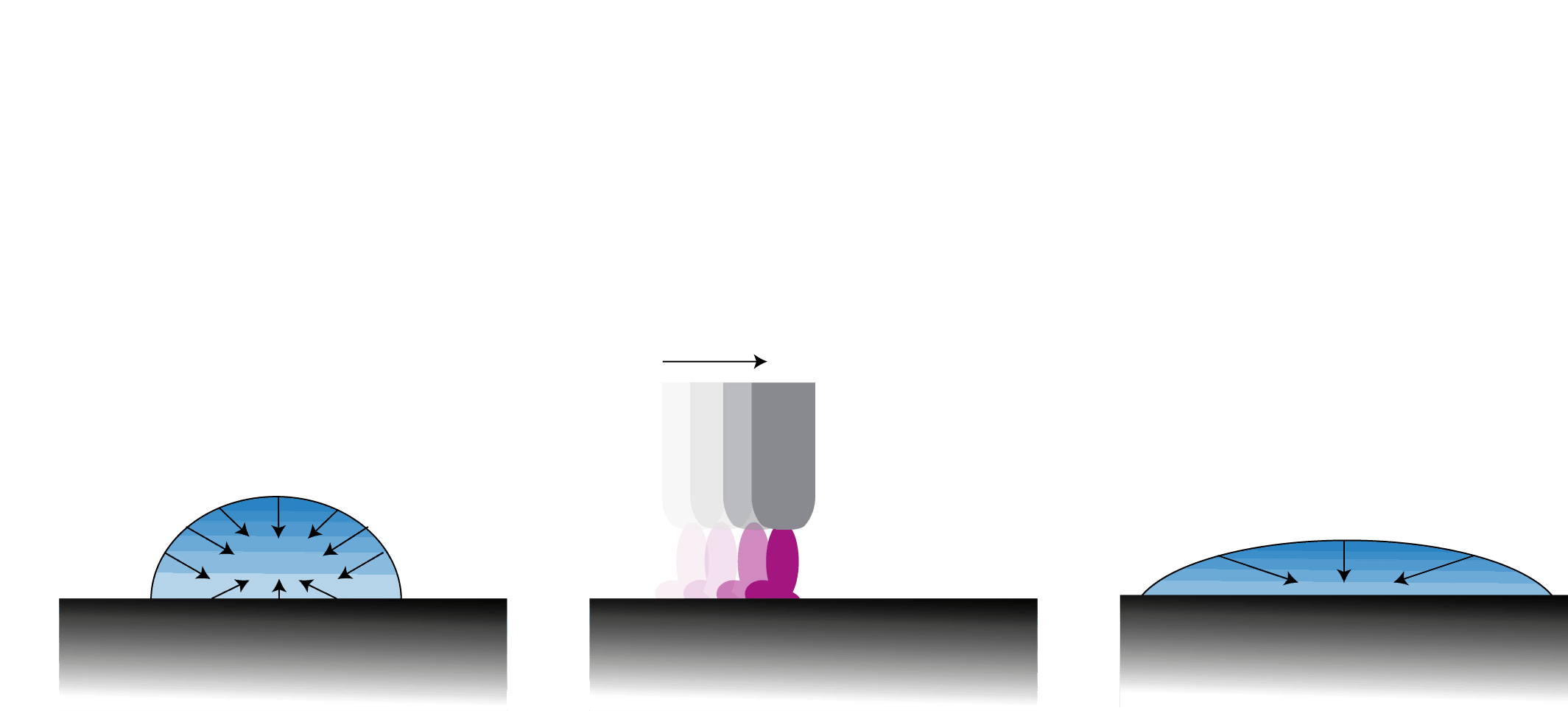

Already at the first contact, the wetting behavior of the liquid can be used to estimate whether ‘the chemistry is right’. If, instead of a closed film, many individual droplets are formed, it can be assumed, for example, that an adhesive bond will not be flat and therefore less effective. This is an effect that can often be observed on plastic surfaces. By treating such surfaces with atmospheric pressure plasma, they can be chemically modified so that the liquid binding partners wet them better (Fig. 1).

In the initial state (left in the picture), plastic surfaces are typically difficult to wet, which is made clear by the round shape of the droplets of liquid deposited. By coating the surfaces with a plasma flame (center), the molecular structure of the flame can be changed in such a way that the applied droplets dissolve (right) and a significantly improved wetting behavior is achieved. This is a decisive prerequisite for good adhesion in processes such as bonding, coating, varnishing and printing.

Invisibly optimized surface

In addition, this invisible change in the surface ensures an optimized bond after the liquid has hardened, whether for gluing, painting, printing or dispensing. The reason for the adhesion improvement is the so-called activation, the interaction between the solid surface and the highly reactive chemical species of the plasma. This is generated by supplying energy to a gas, for example the ambient air, until the electrons are released from the atomic bodies of the gas molecules and short-lived ions and radicals are formed. These react with each other, but also with the molecules that form the surface of a plastic body. For example, the surface can now be much better wetted by generating polar molecular end groups. […]

Read the full article >>