A Novel Computer-Controlled Maskless Fabrication Process for Pneumatic Soft Actuators

Authors: Tinsley, L. J. & Harris, R. A.

Publication: A Novel Computer-Controlled Maskless Fabrication Process for Pneumatic Soft Actuators, Actuators, 2020, 9(4), 136.

First published: https://www.mdpi.com/2076-0825/9/4/136/htm

Total recap:

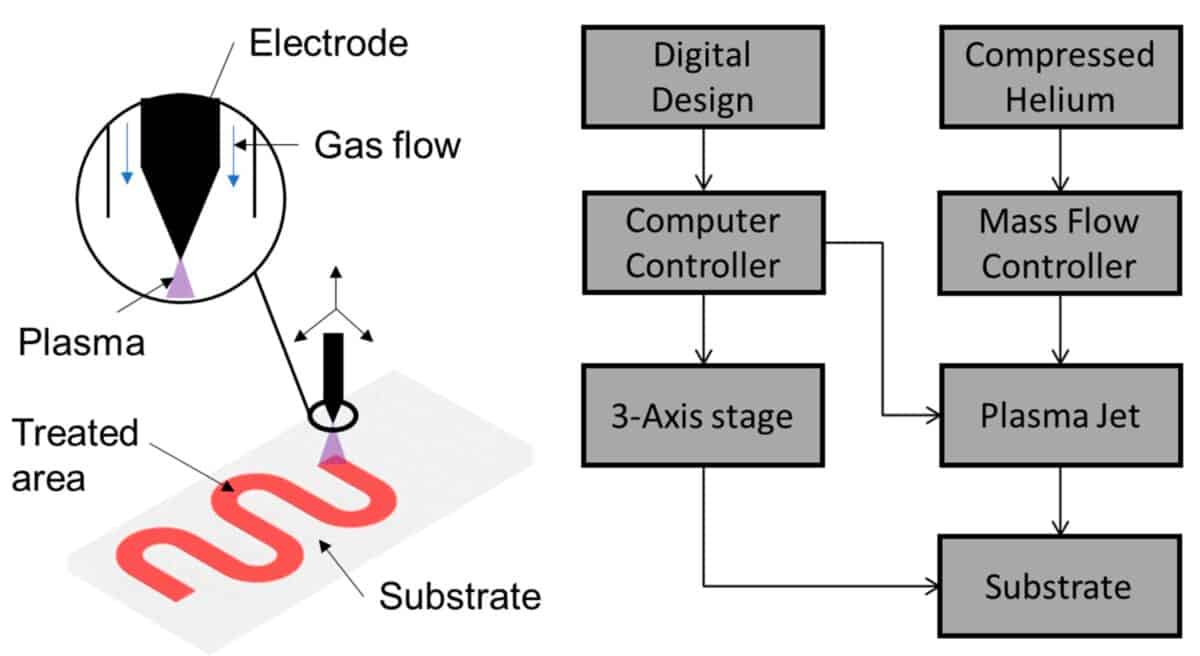

Soft robots use compliant and elastic materials throughout their structure. The inherent properties of the constituent materials result in fundamentally different behaviour compared to their rigid counterparts. Currently, template-based, and additive manufacturing techniques are commonly used for the fabrication of pneumatic soft actuators. While the complexity of the actuators increases, the limitations of these processes become obvious. With moulding, the geometry is limited, and personalization of individual parts is complex. Fabrication techniques based on 3D-printing make the use of different materials possible, but there are limitations in resolution, speed, materials, and scalability. To tackle this task Tinsley and Harris used computer-controlled localised plasma treatment with the piezobrush® PZ2-i to selectively modify the chemical behaviour of silicone and PET to produce pneumatic soft actuators.

For this process a manufacturing platform was generated, by placing the piezobrush® PZ2-i in a 3-axis actuation platform. The bonding was carried out between the silicone Ecoflex 00-50 and a PET sheet. With their difference in stiffness, this material combination is well suited for soft actuators with bending properties.

For the bonding process both, the silicone Ecoflex and PET were selectively treated by plasma. The PET sheets were then immersed in a 1% solution of 3-aminopropyltriethoxysilane (APTES). Afterwards the two materials were aligned and placed into contact to enable the bonding.

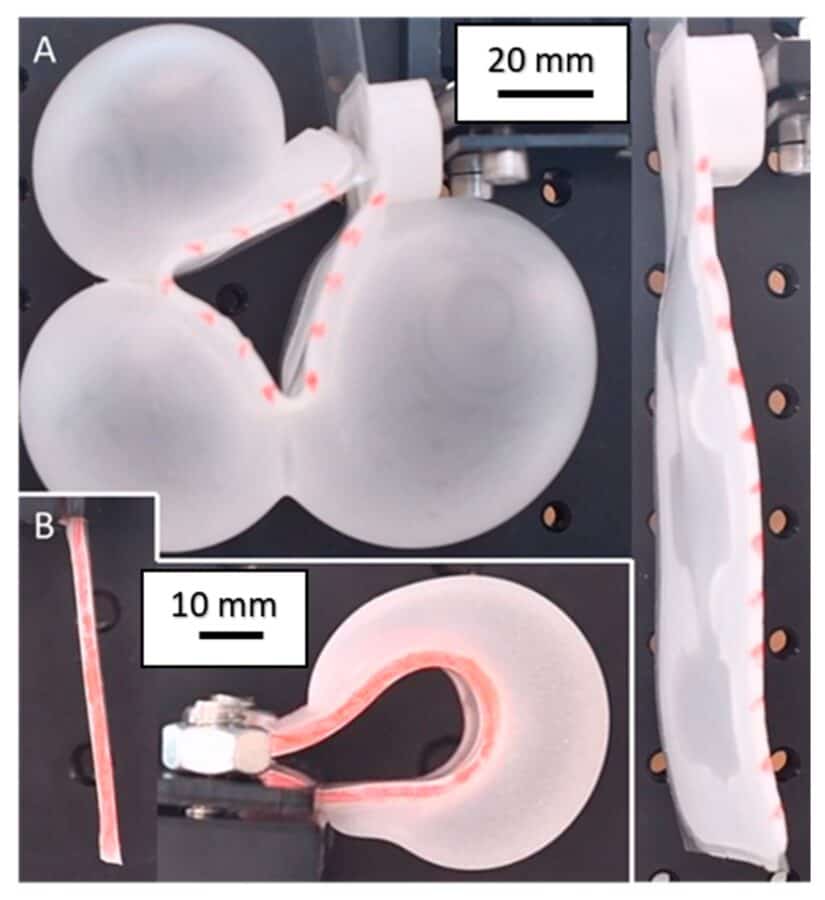

Two actuators were produced by this method to test their properties. Neither actuator failed upon inflation to 16 kPa and 63 kPa, but rather the deformation of the Ecoflex indicated a state close to failure. Via the specific design different inflation levels could be reached of the different chambers (see Fig. 2). The tested simple designs show the robust nature and the designed selectivity of the bonding, but this approach allows the production of actuators as well of much higher complexibility.

In the here presented work, a novel fabrication method for pneumatic soft actuators based on plasma treatment was investigated. Advantages of this approach are that it is digitally driven, like 3D-printing processes, but being much faster and applicable to a wider range or materials. Although this method is currently not suited for actuators requiring feature sizes below 1 mm, it can make the fabrication of larger actuators easier than with conventional methods.

Read the whole publication here.