PiezoBrush PZ3

Effective plasma handheld device for manual use

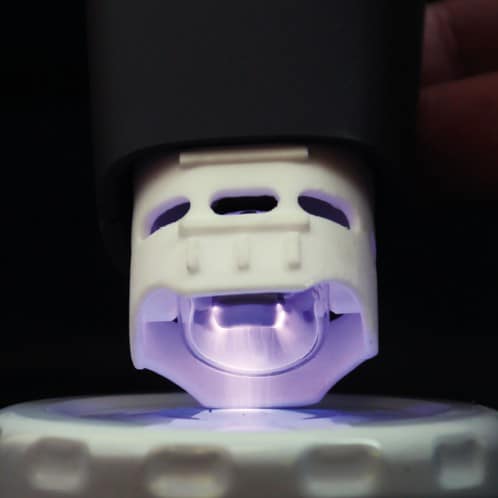

PiezoBrush PZ3 has been designed as a compact plasma handheld device for use in laboratories, predevelopment and assembly of small series. With a maximum power consumption of 18 W, the Piezoelectric Direct Discharge (PDD®) technology is used to generate cold active plasma at a low temperature. The heart of this portable plasma device is the TDK piezo plasma generator CeraPlas™ – a high-voltage discharge device for generating cold atmospheric-pressure plasma. Plasma is used to increase the surface energy of many materials with high efficiency, as well as to reduce germs and odors.

Fields of application

- Joining technology

- Development and optimization of production processes

- Research facilities and laboratories

- Microbiology, microfluidics and food technology

- Medical and dental technology

- Prototype and architectural model making

- Small-scale production

- Activation and functionalization of surfaces of various materials

- Improvement of wettability

- Optimization of bonding, painting, printing and coating processes

- Surface treatment of plastics, glass, ceramics, metals, semiconductors, natural fibres and composite materials

- Ultra-fine cleaning and odour reduction

Application examples

Medical Technology Ireland 2025 in Galway

On September 24–25, we’ll show you at the trade fair how the MediPlas Evaluation Kit, the PiezoBrush PZ3, and the PiezoBrush PZ3-i open up a wide range of applications in medical technology and surface optimization – stop by and experience plasma up close!

Customer reference: Plasma pretreatment for the bonding of PEEK cell holders – Formula Student Team of the Technical University of Berlin (FaSTTUBe)

Better bonding with atmospheric pressure plasma

Prof. Dr. Bender examines the interaction of surface roughness and surface energy with polyethylene and how better bonding with atmospheric pressure plasma can be achieved.

PiezoBrush PZ3 in the online shop

-

Rental unit PiezoBrush PZ3400,00 € / 15 days

excl. 19% VAT

-

PiezoBrush PZ3 (without modules)1.620,00 €

excl. 19% VAT

-

PiezoBrush PZ3 Professional Set2.540,00 €

excl. 19% VAT

Technical details PiezoBrush PZ3

- Electrical connection: 110-240 V / 50-60 Hz

- Power consumption: max. 18 W

- Weight: 110 g

- Design: Handheld unit with plug-in power supply, integrated fan

- Sound pressure level: 45 dB

- Treatment speed: 5 cm²/s

- Typical treatment distance: 2 – 10 mm

- Typical treatment width: 5 – 29 mm

Modules

Different surfaces have to be activated with the appropriate accessories to achieve an ideal result. Currently five different modules are available for the PiezoBrush PZ3 plasma handheld device. The PDD technology used to generate the cold plasma in PiezoBrush PZ3 is based on the discharge of high electric fields. Therefore, the electrical conductivity of the component to be treated is of decisive importance when choosing the modules.

Modules in the online shop

Display

For process control of plasma treatment, the PiezoBrush PZ3 is equipped with various features that can be selected and modified via the display:

- Process control

– Stopwatch: For monitoring the treatment time

– Countdown: Time setting with automatic switch-off function

– Metronome: Acoustic feedback after defined treatment time - Power adjustment: Reduction of plasma power in several increments

Stand for PiezoBrush PZ3

The stand has been designed for the PiezoBrush PZ3 to allow hands-free operation of the handheld device. The height and angle of the stand can be easily and quickly adjusted according to customer requirements. The rubber studs on the base of the stand ensure a secure footing.

Accurate and reproducible processing of substrates is possible with the stand. The included support plate enables the treatment of conductive and non-conductive substrates.

The stand consists of a frame, a clamping device for holding the PiezoBrush PZ3 and a lay-on plate. The stand and its components can be stored in the supplied case.

Fields of application:

- Laboratory

- Dental technology

- Small series

The dimensions of the stand are (W x H x D): 78 mm x 190 mm x 180 mm

FAQs

Downloads

| Description | Language | Download |

|---|---|---|

| Manual | ML | Manual |

| Flyer | EN | Flyer |

| Brochure | EN | Brochure |

| Comparison PiezoBrush PZ2 and PiezoBrush PZ3 | EN | Flyer |

| Whitepaper: Operation Principle and Characteristics | EN | Whitepaper |

| Whitepaper: Ozone control | EN | Whitepaper |

| Flyer – PiezoBrush PZ3 in the dental lab | EN | Flyer |

| Whitepaper PiezoBrush PZ3: endurance test for standard module | EN | Whitepaper |

| Aufbauanleitung PZ3 Stativ / Assembly instruction PZ3 stand | ML | Aufbauanleitung PZ3 Stativ / Assembly instruction PZ3 stand |