Surface Energy Analysis of Dental Implants after Plasma Activation

with the piezobrush® PZ3 with the DataPhysics Instruments OCA-PDDS

Today, DataPhysics Instruments stands for high-performance, high-quality and innovative solutions in the field of surface and interface metrology worldwide. In collaboration with relyon plasma, the surface energy analysis of dental implants with and without plasma treatment is being investigated.

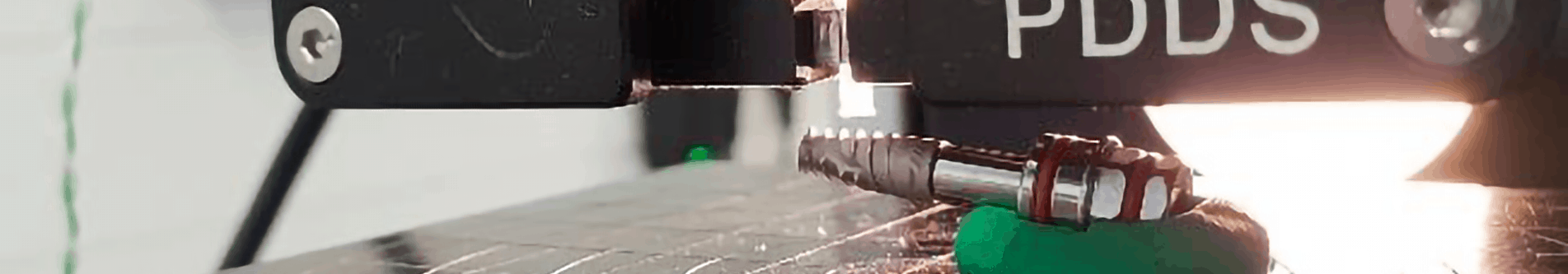

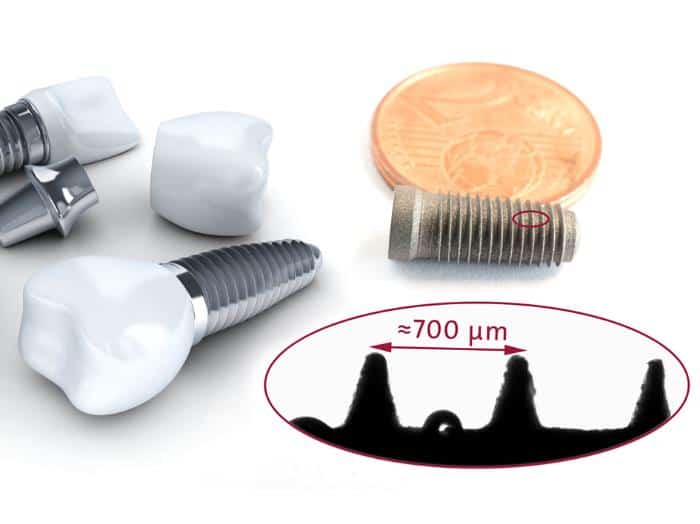

The surface treatments of dental implants have attracted more and more attention due to its important utilization in the optimization of implants wetting behavior. Studies have shown that the initial attachment of osteoblasts is improved by increasing the surface energy, which subsequently leads to increased new bone formation after implantation. Thus, various surface treatment devices have appeared and the plasma handheld device piezobrush® PZ3 is widely used in dental laboratories. The surface energy is a vital parameter to verify a successful pretreatment or cleaning process of implant surface. Furthermore, the knowledge of the surface energy facilitates an estimation of the wetting behaviour and adhesive properties of the implants for further processing. However, the surface energy analysis of micro-structured samples (Fig. 1) is still a big challenge, because the available test areas are very small and it require to dose small drops so that the drops don’t touch or wet beyond the edge of the test surface.

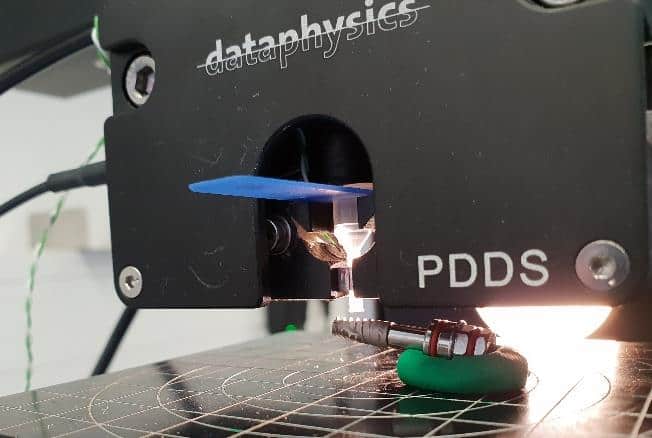

To meet this issue, DataPhysics Instruments offers the picolitre dosing system (PDDS) for dosing the extra-small droplets (down to 30 picolitres). Integrated in the contact angle measuring system OCA 200, a fast and reliable surface energy analysis of implants is guaranteed.

Technique and Method

The optical contact angle measuring and contour analysis systems OCA 200 (Fig. 2) is special for microscopic and macroscopic structures. In combination with the high-performance camera even smallest drops of highly volatile liquids can be monitored. In addition, the electrically driven sample table makes it possible to position micro-structured samples with highest precision and exceptional speed for fast automated measuring procedures. Especially, when it combines with the picolitre dosing system PDDS (Fig. 3), the contact angle measurement on even smaller structures can be analysed, such as the mesh structure of a coronary stent or on single fibres (see application notes of PDDS). Therefore, OCA 200-PDDS allows to generate a single drop that is small enough to fit between the screw threads of a dental implant for its contact angle measurement.

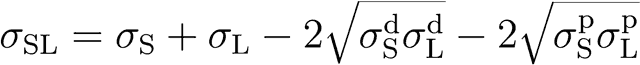

Furthermore, the surface energy (SFE) of a solid is evaluated by contact angle measurements with at least two different test liquids, whose surface tensions including their dispersive and polar parts are known. These dispersive and polar parts are used to calculate the interfacial tension σSL between the solid and a liquid based on a suitable model. Very often, the Owens, Wendt, Rabel and Kaelble model (OWRK-model) is used, which considers the geometric mean of the dispersive and polar parts of the liquid’s surface tension sL and of the solid’s surface energy ss (equation 1):

Substituting this expression in the Young equation, the polar and the dispersive part of the solid’s surface energy can be determined from the regression line in a suitable plot.

Hence, the OCA 200 with PDDS is an ideal technique for the surface energy analysis of dental implants.

For the plasma activation the piezobrush® PZ3 is used. This handheld device uses a piezoelectric element to transform the low input voltage to a high voltage output to create cold atmospheric plasma. A plasma treatment has the effect of surface activation and fine cleaning, which typically both have impact on the surface energy and on its partition in a polar and unpolar fraction.

Experiment

In this note, one ceramic dental implant and two metallic dental implants were used as samples for the measurement. The packaging was removed from dental implants with as little contact as possible and the surface energy of them was analysed firstly without any further cleaning and treatment. In a second step the dental implants were treated with the plasma handheld device piezobrush® PZ3 from relyon plasma, using the Module Standard for the ceramic implant and the Module Nearfield for the titanium dental implant. Cold atmospheric pressure plasma with a temperature of less than 50°C is used for surface pre-treatment of dental implants to increase the surface energy and thus the osseointegration.

The surface energies for untreated and plasma treated implats were determined indirectly via contact angle measurements by the use of two test liquids with known properties. DataPhysics Instruments recommends using diiodomethane, ethylene glycol, thiodiglycol and water as standard test liquids for the determination of the surface energy. However, the viscosity of thiodiglycol is too high for dispensing drops with the PDDS. Note that, in any case, it is important to make sure that the selected test liquids do not chemically react with the substrate to be analysed. Thus, water and diiodomethane were chosen in this note.

The samples were fixed and orientated vertically with plasticine on the sample stage of the analyzing system OCA 200-PDDS (Fig. 3).

To ensure proper contact angle measurement with unhindered wetting, the PDDS had to be controlled so that it generated test liquid drops with wetting areas smaller than the screw threads of the dental implants. One single droplet was disposed between the screw threads of the dental implants each time. To ensure the accuracy and reproducibility of the result, each liquid was tested three-fold. After automatic evaluation with the SCA 21 software module, the average CA values and SFE of the three samples were obtained.

Results

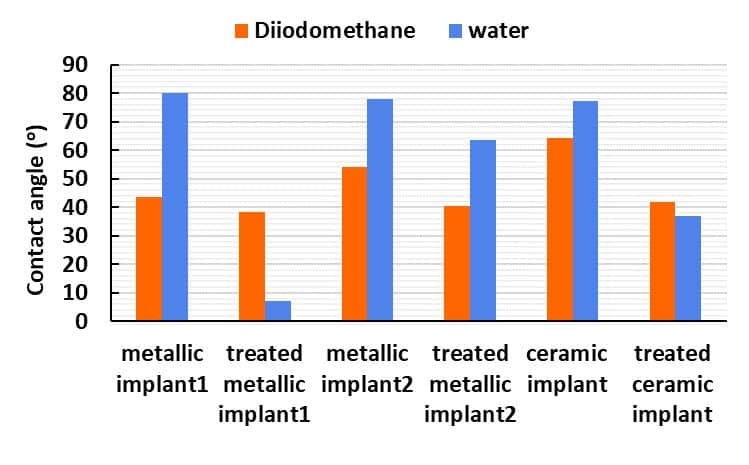

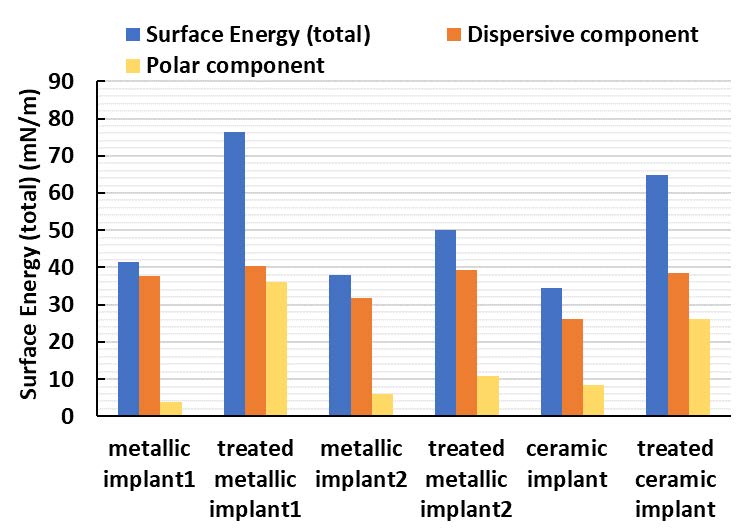

Wettability is of major importance for all kinds of surface treatments. To have a deep understanding of the wettability difference between the original and treated dental implant surfaces, the contact angle and surface energy measurements of water and diiodomethane on these surfaces were carried out.

treated implant surfaces.

with the polar and dispersive components

The contact angle values of treated implants surfaces are lower than of the untreated surfaces, indicating the surfaces become more hydrophilic after surface treatments (Fig. 5). Using the contact angle values, the surface energy of all implants has been calculated according to OWRK (Eq. 1). Fig. 5 illustrates the respective results together with the polar and dispersive components of the SFE. The total and polar components SFE of all treated implant surfaces increased compared to their untreated surfaces, especially, that of treated metallic implant1 and ceramic implants increased significantly. As known, higher surface energies implicate more polar as well as cleaner surfaces. Therefore, the finest organic impurities that are invisible to the human eye, could be simultaneously removed from the dental prosthesis after activating the surface, which are benefcial for further processing.

Summary

The optical contact angle measuring and contour analysis system OCA 200 in combination with the picolitre dosing system PDDS from DataPhysics Instruments provides a simple and reliable method to determine the surface energy of dental implants before and after surface treatment with a piezobrush® PZ3 from relyon plasma.

This techinique broadens the way to study the surface energy of the micro-structured samples, which is also of great importance for improving industrial treatments like painting, cleaning, coating or conglutination.