piezobrush® PZ3 in 3D printing for microoptics

We are very pleased that the University of Stuttgart is using our handheld plasma device piezobrush® PZ3 in 3D printing in two different departments. On the one hand, the handheld device is used in the field of optical design and simulation for surface activation and plasma cleaning of substrates for 3D printing. On the other hand the piezobrush® PZ3 is used in the 4th Institute of Physics for the pre-treatment of glass substrates for 3D printing of microoptics.

Plasma activation in 3D printing

Using the new piezobrush® PZ3 from relyon plasma, glass substrates for 3D printing of micro-optics made of different polymers can be excellently activated at the 4th Institute of Physics at the University of Stuttgart, so that they adhere more reliably to surfaces and can also be used for more robust applications. Claudia Imiolczyk - 4th Institute of Physics - University of Stuttgart

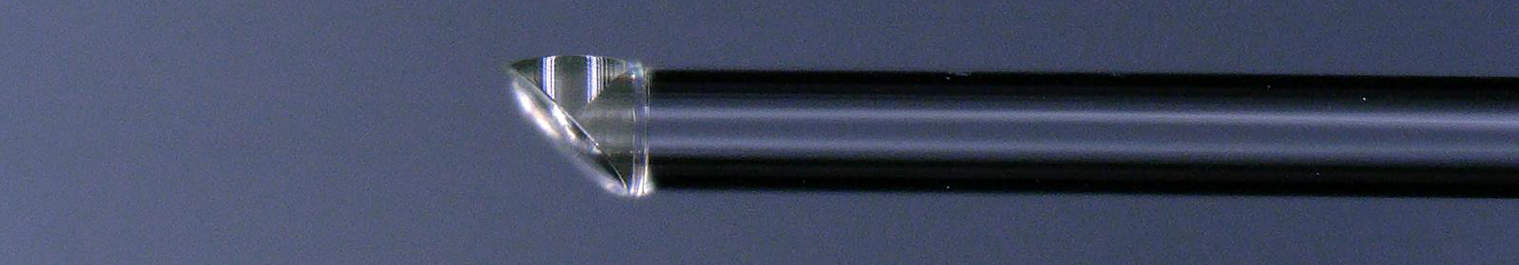

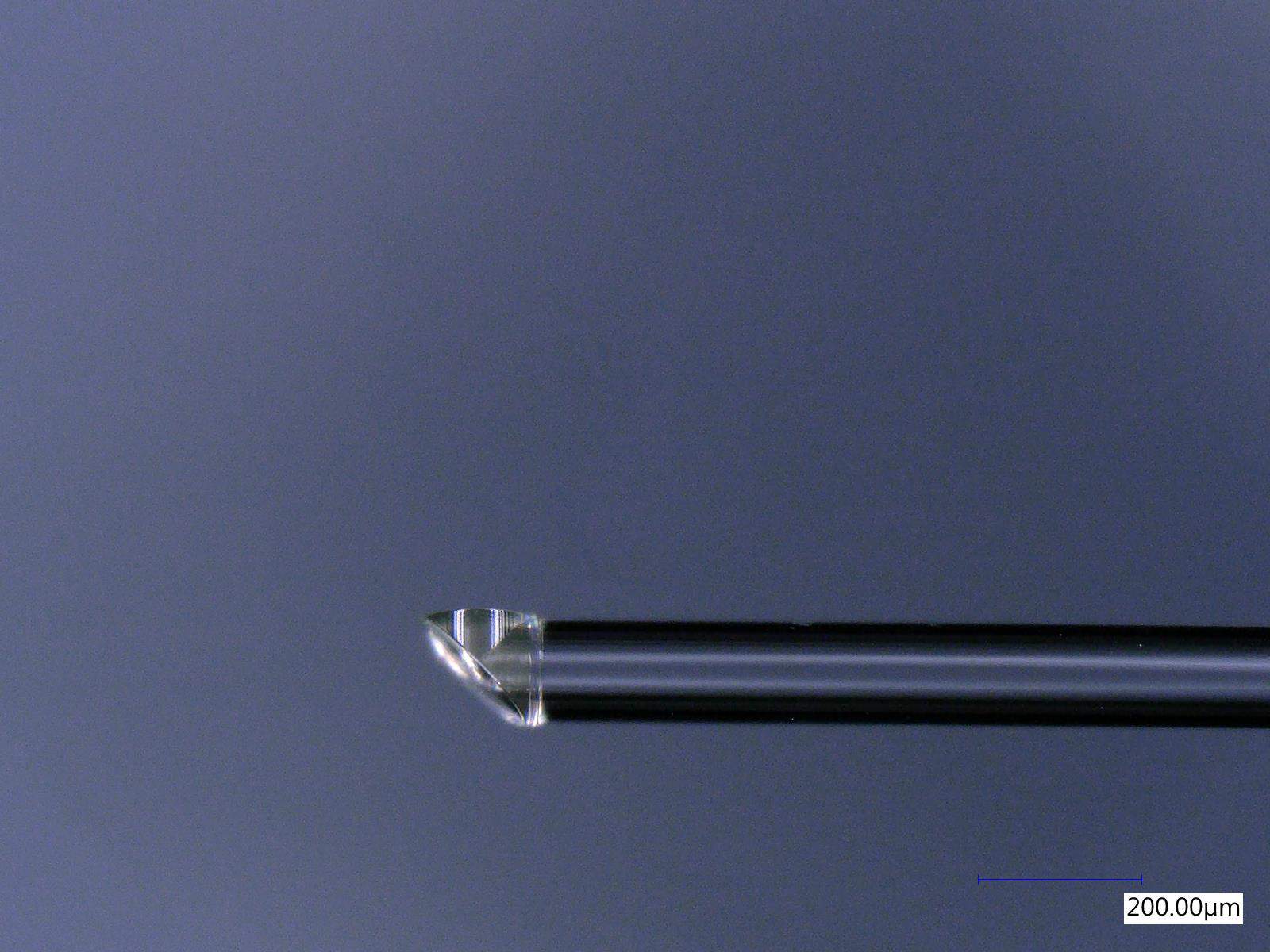

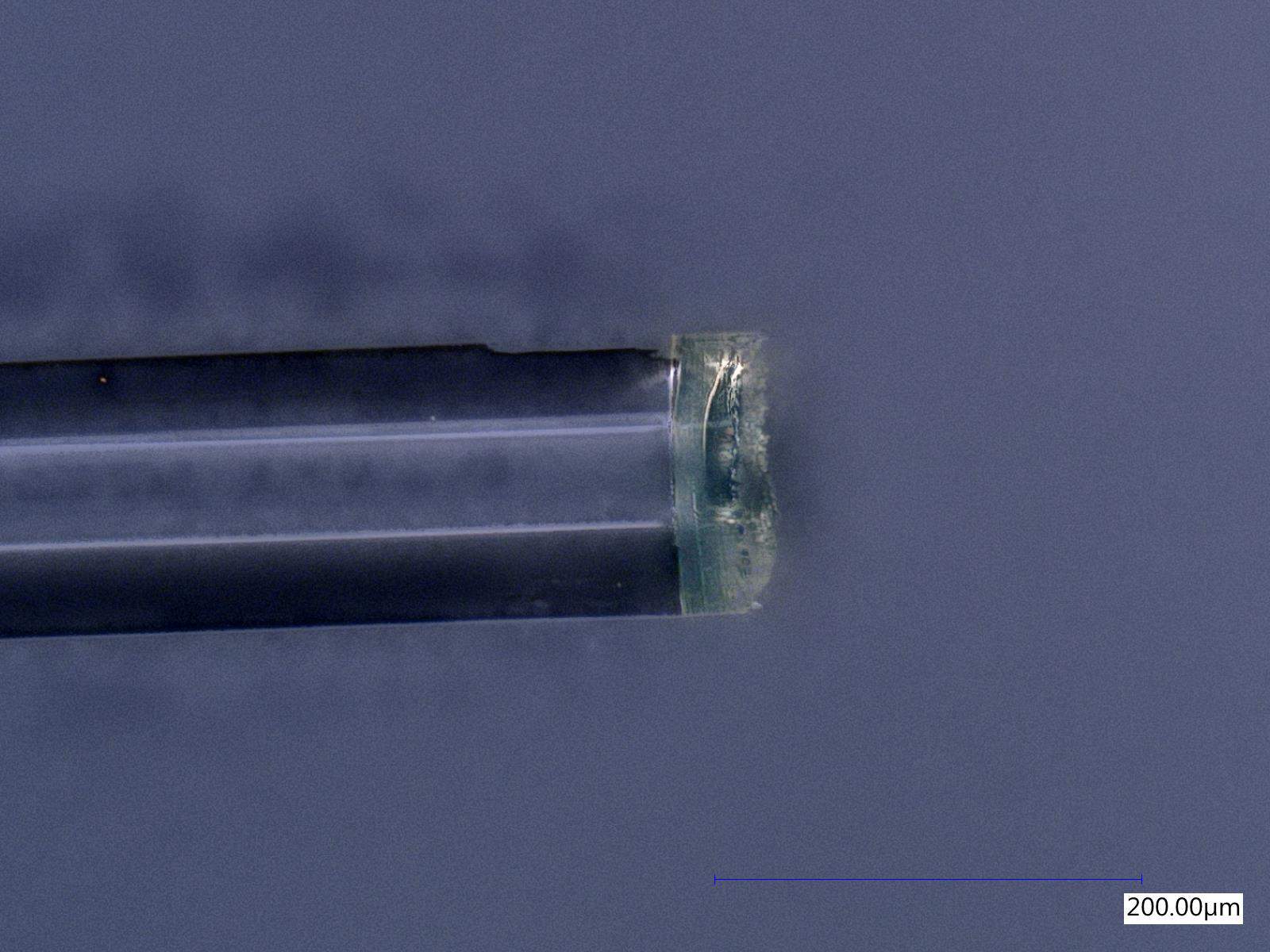

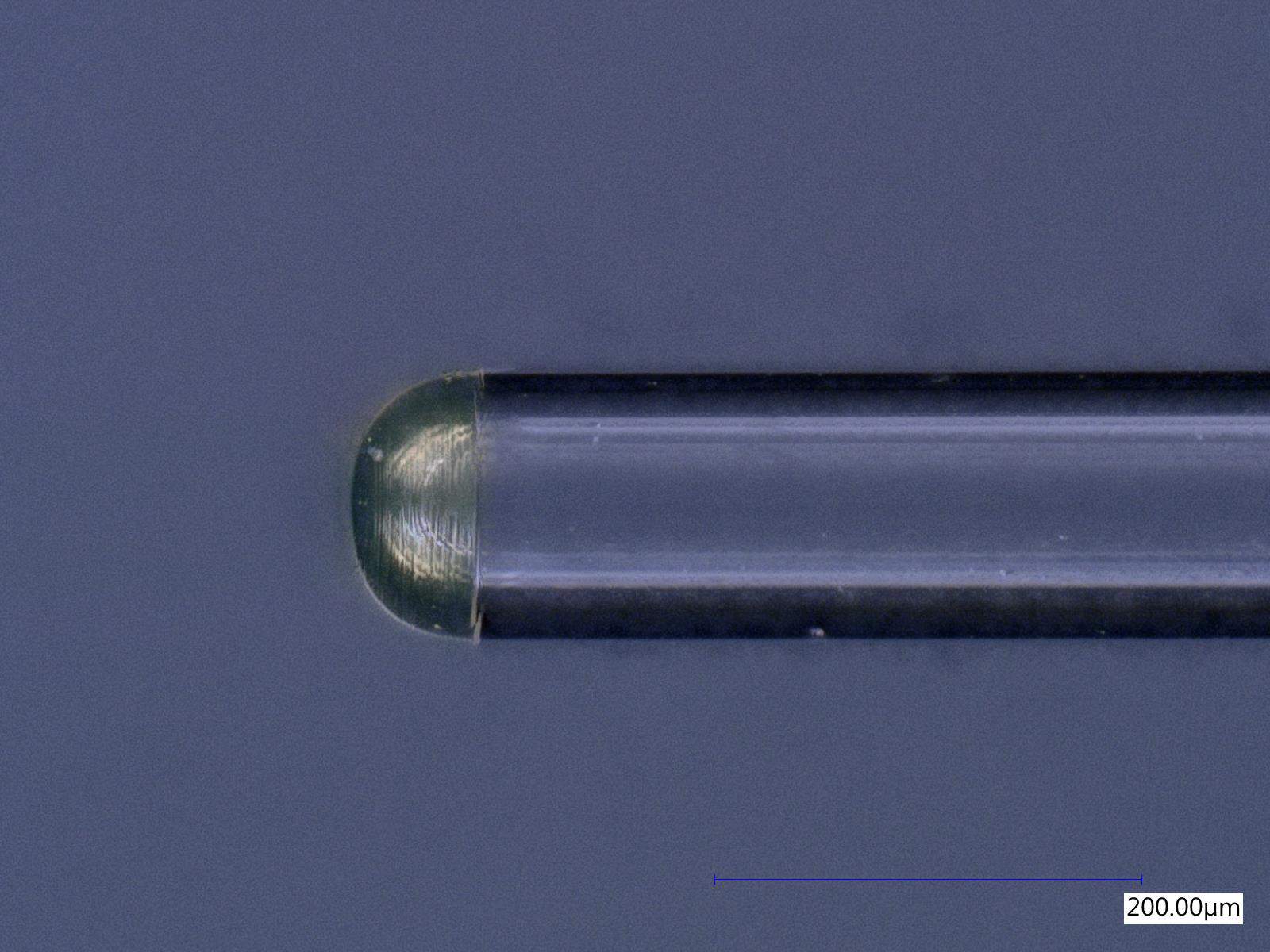

In addition to the activation of ITO-coated glass plates with the “Module Nearfield”, the “Module Standard” is used for the advantageous activation of the end surfaces of glass fibers to be printed, since here small areas (125 µm) can be selectively held in the plasma. At the same time, the application of plasma technology serves to clean these end surfaces, resulting in optimized wavefronts in contrast to simple propanol cleaning.Claudia Imiolczyk - 4th Institute of Physics - University of Stuttgart

Plasma cleaning of glass substrates

The plasma technology of relyon plasma is used at the Institute for Technical Optics at the University of Stuttgart for the simple and user-friendly cleaning of substrates for micro-3D-printing to improve the adhesion of the printed parts. The compact design is particularly useful for activating the end surfaces of optical glass fibers, as these cannot be easily treated in equipment with a plasma chamber.Dr. Simon Thiele - Institute for Technical Optics at the University of Stuttgart

Further information about piezobrush® PZ3 in 3D printing can be found at the overview page.

Get more information >>