Description

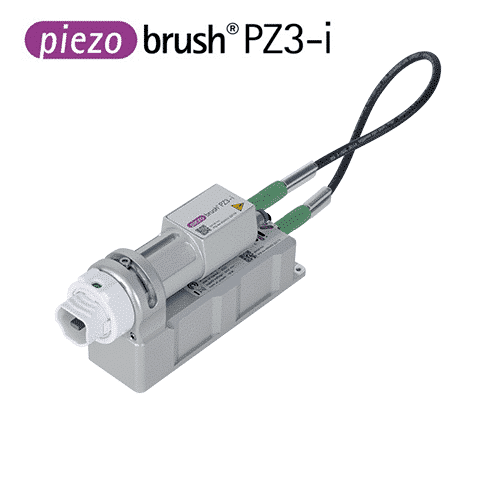

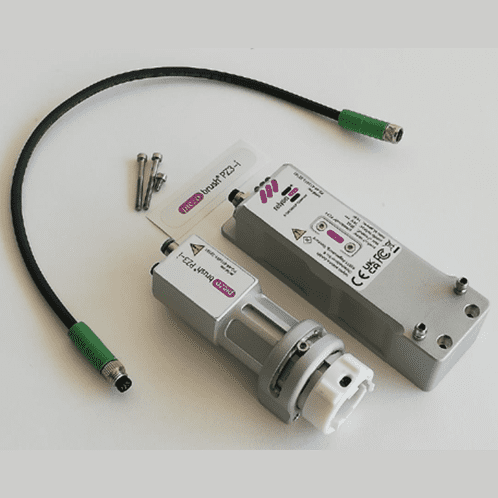

The plasma integration PiezoBrush PZ3-i was developed for integration into new and existing production lines. Based on Piezoelectric Direct Discharge (PDD®) technology, the plasma device generates cold-active plasma. The plasma solution has been designed to be particularly compact, safe and energy efficient. By using atmospheric pressure plasma, the surface energy on many materials is increased, improving wettability.

Application examples:

◊ Inkjet, marking, and pad printing

◊ Dispensing technology, e.g. for housing bonding

◊ Adhesive bonding and labeling applications in the laboratory and medical technology

◊ Laminating processes, e.g. in packaging technology

◊ Optimization of adhesive bonding processes

◊ Targeted improvement of wettability

◊ Alternative to chemical primers, flaming processes, chemical and mechanical roughening

◊ Microbiology, microfluid and food technology

Detailed product information can be found on the product page PiezoBrush PZ3-i.