Disinfection with plasma

Plasmas reduce concentrations of pathogens upon contact with contaminated surfaces. Plasma destroys bacteria, viruses, fungi and prions; it also removes toxins and further organic contaminants. Even complete sterilization is possible with prolonged exposure to the plasma. Most importantly, strong disinfection can be achieved with atmospheric pressure air plasmas, produced by a Piezoelectric Direct Discharge (PDD) ora Dielectric Barrier Discharge (DBD). Thus, plasma disinfection and sterilization does not require expensive vacuum equipment or toxic chemicals, making the process cheap and environmentally friendly. Cold atmospheric pressure plasmas of PDD and DBD discharge make the plasma disinfection very gentle comparing to the standard disinfection procedures using pressurized hot air, pressurized hot water vapor or toxic substances. It affects only a very thin surface layer. Because of this, plasmas can disinfect a variety of sensitive surfaces, including living tissues and even open wounds.

Plasma disinfection mechanism

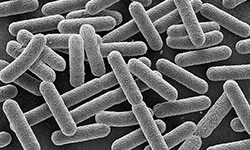

The chemically active, cold atmospheric plasma triggers a multitude of physical and chemical processes. The decomposition of organic molecules of living microorganisms is achieved on the one hand by bombarding them with electrons, ions and short-lived neutral chemical species and on the other hand by the oxidizing effect of the highly reactive chemical species in the plasma. In addition, the ion bombardment breaks the hydrogen bonds of organic molecules. This leads to a reduction of ultrafine organic impurities and germs up to the complete sterilization of the treated surfaces. The following reaction agents and processes contribute to the disinfection:

- Ions and electrons bombard the surface in direct contact with the ionized plasma volume. Having high energies, they are by far the strongest agents of disinfection, as they break hydrogen bonds of organic molecules, such as those forming cellular membranes.

- Reactive oxygen species are oxygen atoms and chemically active molecules containing oxygen in ground or excited states, as well as their ions. They indiscriminately attack all organic molecules of living organisms. Most importantly, they destroy bacteria capsules and cell walls. Hydrogen peroxide (H2O2) is also very reactive. Ozone (O3) is a stable long-lived molecule known as a powerful oxidant. It also destroys the cell walls.

- Reactive nitrogen species are a family of antimicrobial molecules including nitric oxide (NO), nitrogen dioxide (NO2), peroxynitrite anion (ONOO−), nitrous acid (HNO2). They are less reactive comparing to the oxygen species, but their lifetimes are sufficient to penetrate into deeper layers of the tissues.

Advantages of disinfection with atmospheric pressure cold air plasmas

Atmospheric pressure plasmas, and especially the plasma of the piezoelectric direct discharge, have demonstrated a strong disinfection capacity. Comparing to the standard disinfection and sterilization methods using pressurized hot air of 170 C, pressurized hot water vapor of 120 C, wet chemistry, or low-pressure plasmas, the cold atmospheric pressure air plasmas offer the following advantages:

- Treatment at the atmospheric pressure enables disinfection of objects that can be damaged by vacuum or overpressure

- No expensive vacuum or pressurized chambers and pumps

- No wet chemistry

- Ultra-fine cleaning, no residues

- Low operating temperature

- Gentle treatment of sensitive surfaces, including living tissues and open wounds

- Air or cheap non-toxic working gases

- Environmental friendliness

Application examples

48. ak-adp workshop in Chemnitz

The 48. ak-adp workshop with the motto: Atmospheric plasmas in complex processes takes place from April 9th to 10th 2025 in Chemnitz.

Over the last few weeks, the Versuchs- und Lehranstalt für Brauerei in Berlin (VLB) e.V. has carried out extensive tests with the MediPlas RONS generator to reduce live cell counts. The experiments showed that the MediPlas system achieved a reduction in live cell counts of more than 6 log levels after just 5 minutes.

The study investigated the effects of cold atmospheric plasma (CAP) on the shelf life of pork. Different treatment times were tested for the pork samples to evaluate their effects on the natural microbiota and the quality of the meat.

Press release: Plasma in the medical sector

Relyon plasma presents the versatile application possibilities of atmospheric pressure plasma within the webinar series “Plasma in the medical sector”. Starting with the production of medical products, through the dental industry to direct use in medicine and skin treatment.

piezobrush® PZ3: potential for virus inactivation

The piezobrush® PZ3, powered by the CeraPlasTM F-type piezoelectric transformer (PT), is used to generate an atmosphere with a high concentration of chemically active species and ions.