Atmospheric pressure plasma in electronics production

From November 12 – 15, 2019 productronica – the world’s leading trade fair for the development and manufacture of electronics – will open its doors at Messe München. We will present some application examples for atmospheric pressure plasma at productronica 2019.

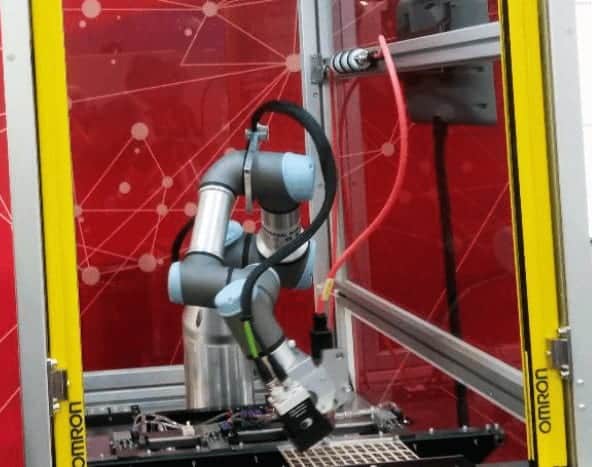

Together with our partner Bridge S. r. l. we are represented in hall B2 at booth 428 at F & K DELVOTEC Bondtechnik GmbH. At the booth our high performance plasma system plasmabrush PB3 was integrated into the Cobocell 4.0. Plasma is used for fine cleaning before bonding. In addition, atmospheric pressure plasma offers different applications for increased productivity and quality also in the line production of electronic assemblies.

Wire bonding

Ideally, wire bonding takes place on clean metal surfaces of the semiconductor component or carrier material. In practice, however, contaminations of the surface frequently occur, which can lead to non-stick on pad (NSOP) or so-called “lifts”. Both cases lead to production failures, downtimes and quality defects. By a previous selective plasma treatment both NSOPS and lifts can be avoided and thus the quality can be increased.

Solder resist

Another application is in adhesive processes on solder resist. This is applied before soldering in order to prevent the surfaces coated with it from being wetted with solder on the printed circuit board. However, such areas are often to be coated, glued or potted in a further step, which is difficult because the surface has very poor wetting properties. The solder resist can be activated by a plasma treatment, so that coating, gluing or potting of circuit boards is possible without any problems.

Flux

A flux is a substance added during soldering which improves the wetting of the workpiece by the solder and removes the oxides on the surfaces by chemical reaction. However, these are often corrosive, corroding or harmful to health and should be removed from the surface after soldering. Therefore the parts are cleaned after soldering with the plasmabrush.

Selective fine cleaning and activation

Atmospheric pressure plasma offers the possibility to remove organic as well as oxidic impurities from the decisive surfaces in the existing process and to make repellent layers either completely or selectively wettable. In contrast to low-pressure plasma, the jet of an atmospheric pressure plasma system can be easily integrated into the production line without significantly increasing cycle times. This makes this technology a cost-effective and attractive way to improve quality.

Plasma and adhesive

Our partner John P. Kummer GmbH will also be demonstrating the interaction of plasma activation with various adhesives and adhesive tapes at Stand 301 in Hall A4. The piezobrush® PZ2 will be demonstrated and tested live on the stand.

Discover plasma in electronics production at productronica 2019!