Surface tension and surface energy

The surface tension and surface energy (for liquids, it is equal to the surface tension) determines how much energy is needed to break the chemical bonds when a new surface of a solid or liquid is created. It is used to describe wettability. This is particularly important when materials such as plastic are to be bonded, painted or printed. If a surface is highly energetic (polar), the adhesion of printing inks or adhesives to it is considerably higher than with low-energy (non-polar) surfaces.

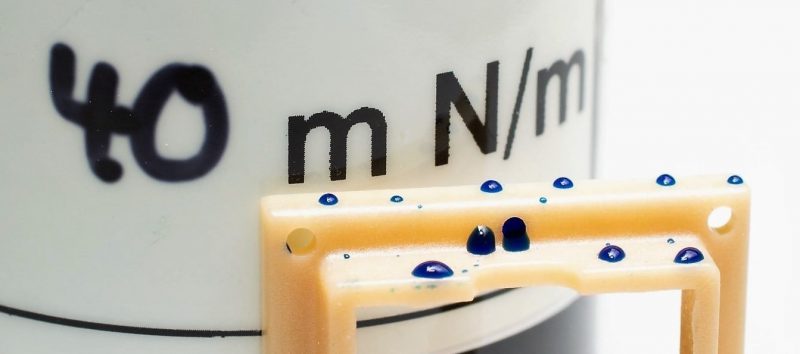

Fig. 1: Untreated PPS components cannot be wetted with 40 mN/m test ink

Fig. 2: After plasma treatment, the component is completely wetted with a test ink of 60 mN/m.

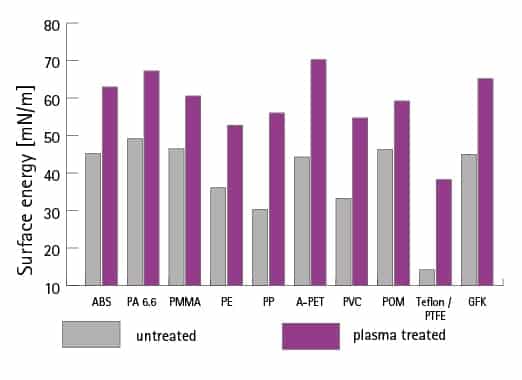

Improved surface tension by plasma treatment

For many industrial processes, it is important that materials, e.g. plastics, have a specific surface energy in order to achieve a certain quality of the subsequent processes. For this reason, plasma is often used as a pre-treatment to remove the finest contaminants and also to compensate any differences between material batches. The table clearly shows that the wettability of various plastics can be increased significantly by plasma pre-treatment with the piezobrush® PZ2.