Pre-treatment for printing using plasma

Pre-treatment for printing and coating using plasma has established itself as a standard process in all common printing processes such as digital printing, pad printing, screen or offset printing. The adhesion of the printing inks and varnishes to the surface is enormously improved by pre-treatment with plasma, which significantly increases the print quality. The surfaces of many materials such as metals, glass, ceramics and even natural materials such as wood and textiles are often very difficult to print on but are susceptible to plasma functionalization. Plasma pre-treatment allows many polymers with typical “non-stick” surfaces to be successfully printed and coated after plasma treatment.

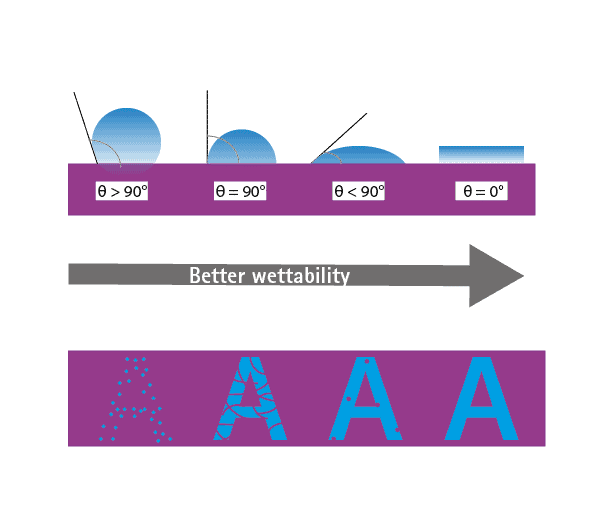

The picture below illustrates the interaction of surface energy, printing ink and plasma. In the upper picture we see a drop of ink applied to a surface and below that the print result. The first drop has a very large contact angle of more than 90° and therefore wets the surface very poorly, which has the effect that the ink contracts on the surface and does not wet evenly. The two drops in the middle already have a flatter contact angle, which improves the printing result accordingly. The best result is obtained when the contact angle is 0°, as then the ink drops wet the surface well and creates an even print image.

The increased wettability results in larger ink droplets with a low contact angle. This results in a print result with sharp edges and high color brilliance, as the drops flow into each other and thus wet the entire surface.

Plasma processing achieves the surface functionalization effect through a combination of ultra-fine surface cleaning from organic contaminants, modification of the surface topography and deposition of functional chemical groups.

Plasma functionalization of surfaces can be performed at the atmospheric pressure using air or typical industrial gases including hydrogen, nitrogen and oxygen. It avoids expensive vacuum equipment or wet chemistry, which positively affects its costs, safety, and environmental impact. Fast processing speeds further facilitate numerous industrial applications.

Advantages of the pre-treatment for printing with plasma

Plasma cleans, strengthens and chemically functionalizes the surface. All these effects, which are required for a good printing result, are achieved simultaneously in a single step:

- Ultra-fine cleaning, no residues

- Better ink adhesion

- High resistance to aging, handling, and weathering

- Excellent colour brilliance

- Gentle, non-destructive surface treatment

- No wet chemistry

- Air or cheap non-toxic working gases

- Environmental friendliness

- No expensive vacuum equipment

- Fast processing speeds

- Easy integration into existing production lines

Application examples

Customer reference Prints and more

In digital and pad printing, plasma treatment achieves ultra-fine cleaning of the printing surface and significantly improves adhesion.

Plasma treatment for improved print quality in coding and marking printing

Plasma is becoming increasingly important in coding and marking printing, as the printing of data matrix codes requires high print quality and abrasion resistance.

piezobrush® PZ3-i beta test report

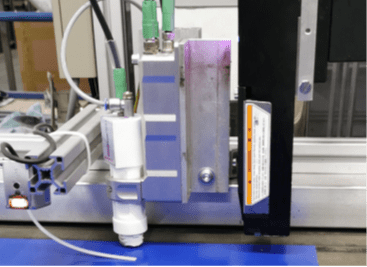

A market-leading company in the development, production and distribution of surface treatment tooling solutions uses the new piezobrush® PZ3-i in conjunction with the KEYENCE MK-G1000SA continuous inkjet printer to safely and effectively mark PTFE fabrics.

Product launch piezobrush® PZ3-i

The highlight of this year’s trade show appearance at Bondexpo is the presentation of the compact integration solution piezobrush® PZ3-i for the first time ever. The cold plasma device is designed for integration into existing production lines and is therefore compact, safe, and efficient. Thus, it is ideally suited for pre-treatment prior to gluing, printing, and laminating.

Reference: University of Stuttgart

At the University of Stuttgart the plasma handheld device piezobrush® PZ3 is used for plasma activation in 3D printing for microoptics.