Polytetrafluorethylen (PTFE)

Polytetrafluorethylen (PTFE)(Polytetrafluoroethylene) belongs to the class of thermoplastic polyhalogenolefins and it is highly inert and thermally stable up to 260°C (500°F). Even aggressive acids such as aqua regia cannot corrode PTFE; it is also extremely resistant against all bases, alcohols, ketones, fuels, oils etc.

Surface energy and contact angle

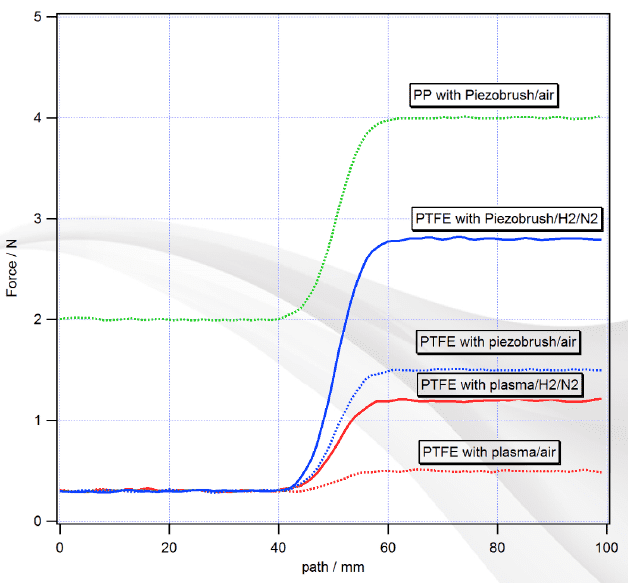

There are almost no materials and adhesives that adhere to PTFE, as the surface tension is extremely low. The contact angle with water is 126°. As a result, PTFE is difficult to wet and hardly sticky. Only a chemical modification of the surface with plasma technology leads to better adhesion values. If PTFE is therefore treated with forming gas in combination with piezo technology before further processing, both the surface energy and the wettability of PTFE are considerably increased. Tensile forces in the peel test permanently reach values which are 8 times higher than without pretreatment. Thus, printing is now possible e.g. in tampon printing.

Application

Due to its chemical inertness, PTFE is used as a coating for applications which include aggressive chemicals. The great variety of possible compounds and the relatively simple solutions provided by this allow for the preparation of highly specific mixtures for a wide spectrum of applications such as shaft seals, groove seals, bellows, or screw joints.

Due to its low friction properties, PTFE is relevant as a dry lubricant (solid lubricant) and as a coating for bearings and seals.

In medical applications, PTFE is used for implants, among other things. On the one hand, its remarkable chemical resistance makes for high durability and good compatibility, on the other hand its smooth surface reduces the risk of blood clotting.

Because it is extremely heat resistant, PTFE can be autoclaved at 130 °C (270 °F). There are also PTFE face implants, which are used in plastic surgery.

In high frequency technology, PTFE is a popular material e.g. for cable insulation, due to its low permittivity and its minimal losses.

In high voltage technology, PTFE is suitable as an electrical insulator due to its high partial discharge resistance and its low adhesive properties regarding surface contamination.

Expanded or elongated PTFE (ePTFE) is a specially processed form of polytetrafluoroethylene with a membrane so fine-pored that it is permeable to steam, but not to water in its liquid state. It thus lends itself to the manufacturing of waterproof, breathable foils for the clothing industry and medical technology.

Learn about our products >>