MediPlas Principle

MediPlas™: more than a simple ozone generator

Medical | Dental | Pharma | Packaging | Food

Dielectric barrier discharge flow reactors stand out as highly efficient technologies for ozone production using oxygen as their base. However, when employing ambient air, the chemistry becomes notably more intricate, involving multiple competing reaction pathways, resulting in a mixture of ozone combined with nitric oxide components, nitric acids, and peroxides. The process parameters that play a significant role in determining the output composition include:

- The composition and humidity of the inlet gas

- The power density of the dielectric barrier discharge

- The amplitude of the electric excitation

- The process temperature

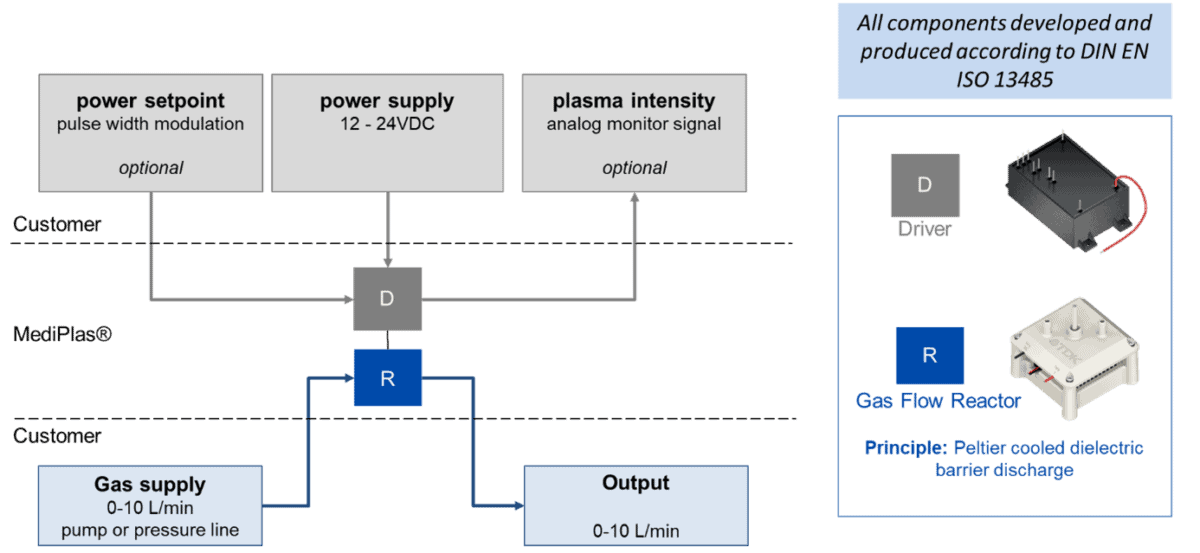

We have developed a reactor tailored for typical flowrates ranging from 0 to 10 standard liters per minute (slm), incorporating integrated active Peltier cooling, which provides excellent control over the process temperature. The specially adapted driving circuit can finely adjust power density (via pulse-width modulation, PWM) and the amplitude of the excitation voltage. Additionally, the driver features a feedback signal that is proportional to the discharge intensity.

With the MediPlas components, constructing a robust, versatile ozone generation system becomes straightforward. Essentially, all you require is a DC power supply and a gas supply or an air pump.

To the MediPlas Reactor product page >>