Dielectric Barrier Discharge Technology – DBD Technology

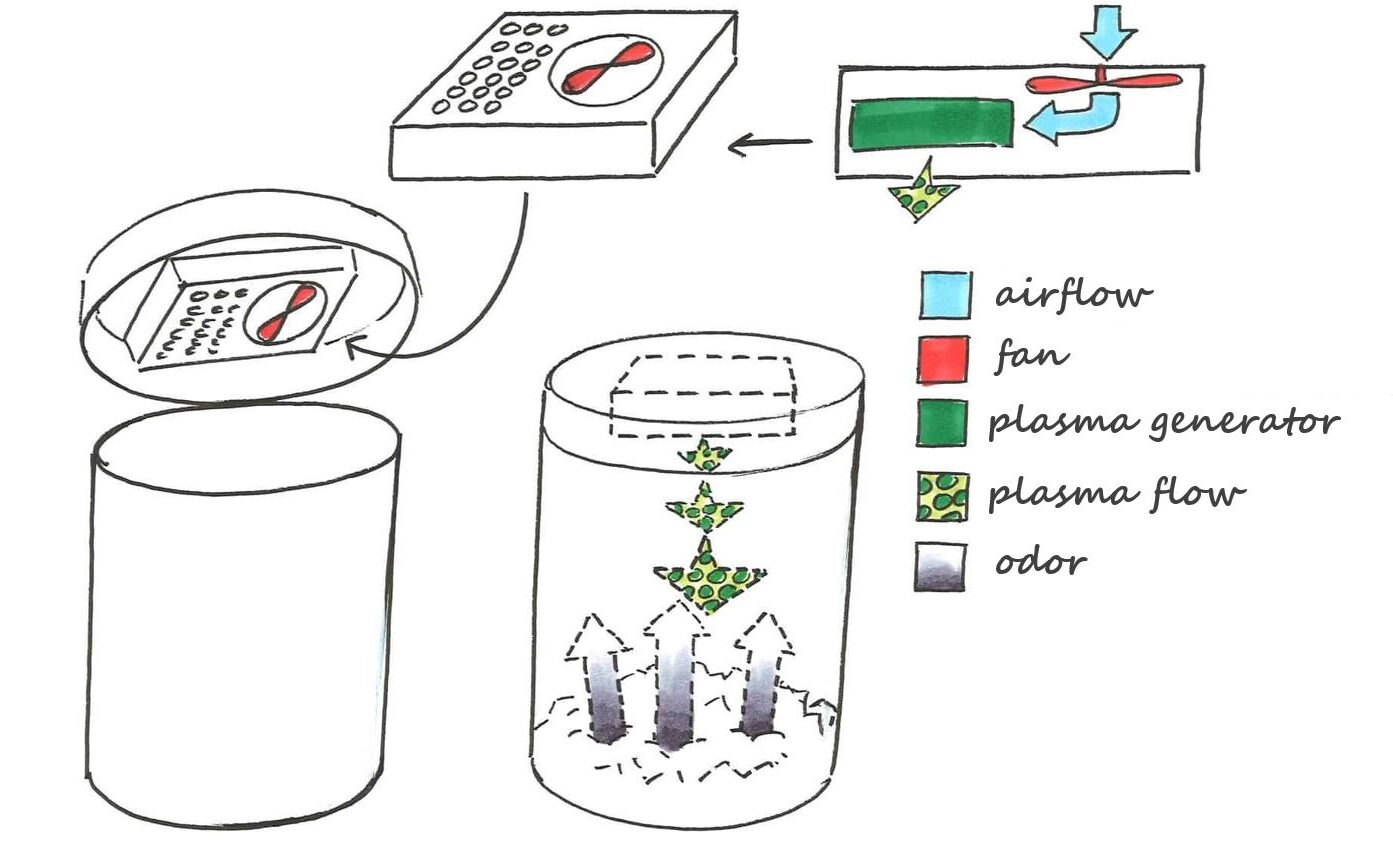

Do you develop applications such as cabinets, ventilation systems or waste bins? Is it particularly important to you to minimize germs, viruses and odours, and at best to neutralize them.

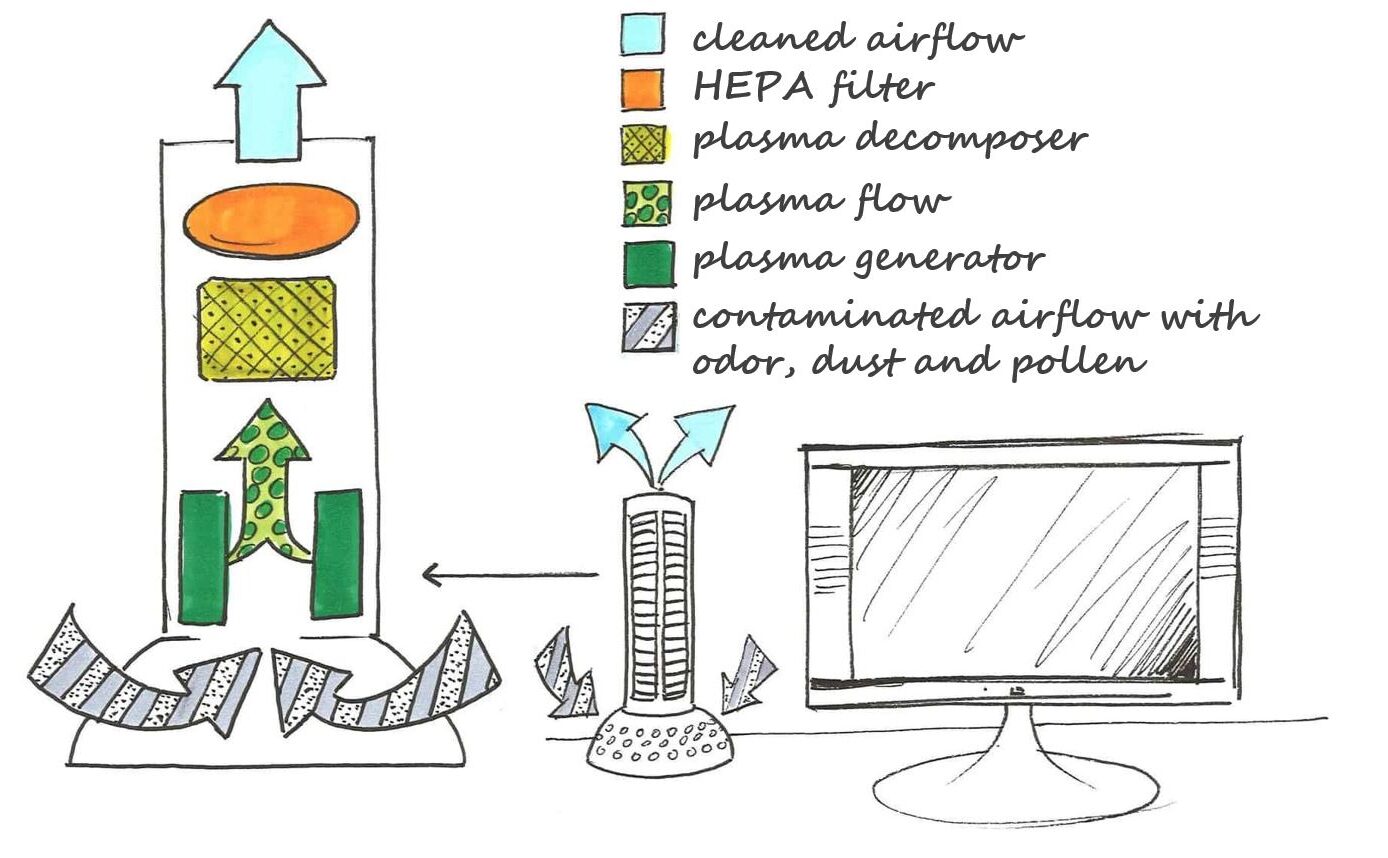

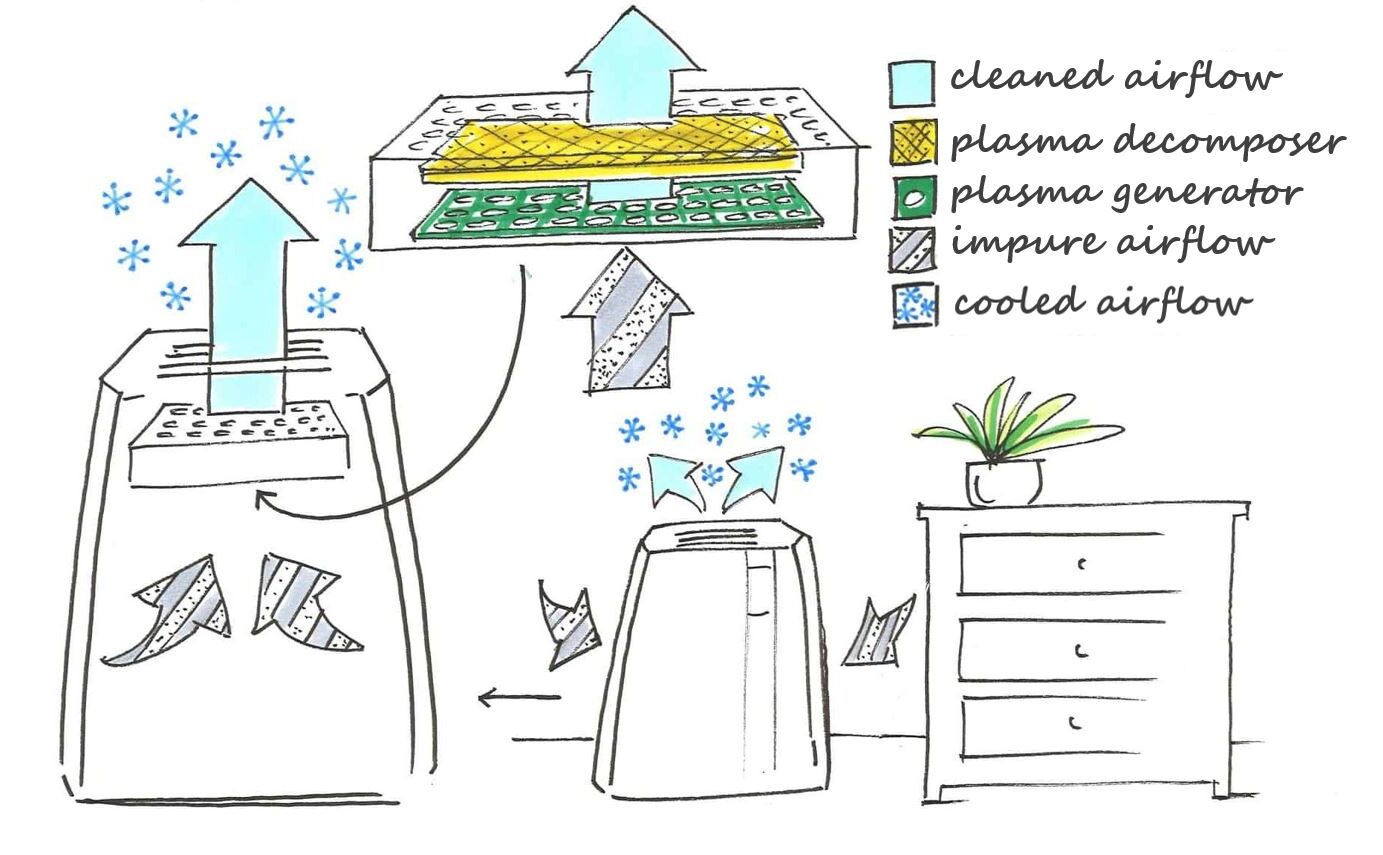

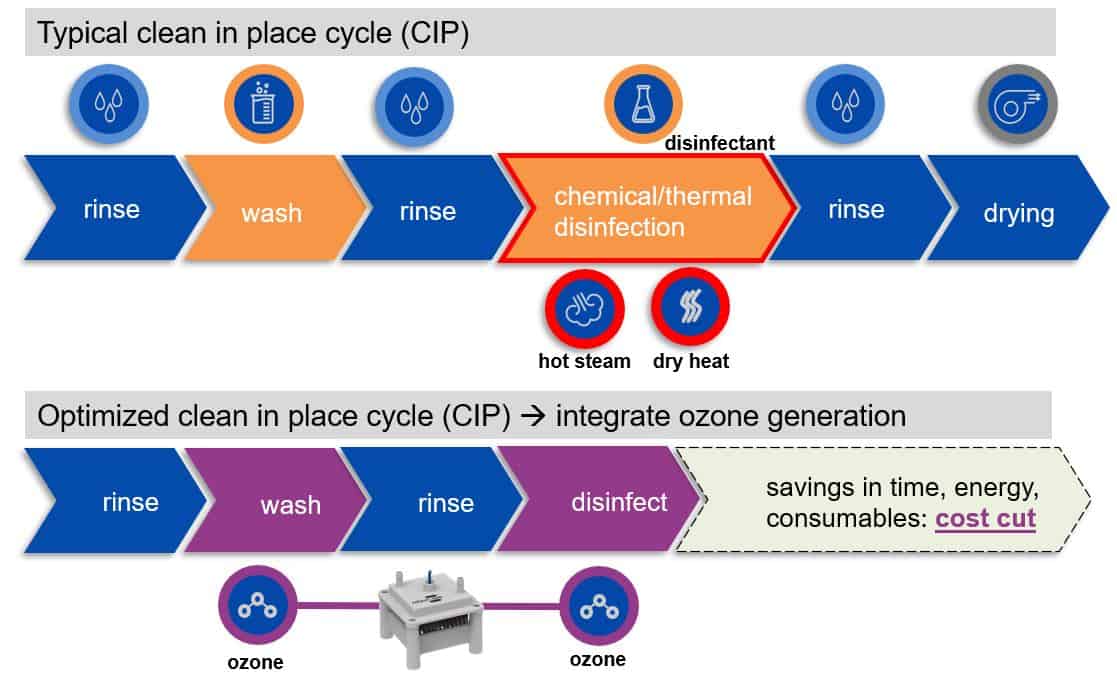

Through the integration of DBD technology odor elimination and germ reduction is quite simply possible! You can completely dispense with additional chemicals, as the DBD Technology is based on a physical process. The modules use the principle of electrical discharge, whereby odours etc. are neutralized by active oxygen. The typical clean in place cycle is optimized:

The most important characteristic of dielectric-barrier discharges is that non-equilibrium plasma conditions can be provided in a much simpler way than with any other technology. Distributed over a surface, microdischarges with a lifespan of only a few nanoseconds pump hot electrons into the gas-phase while the total process remains “cold” (far from thermodynamical equilibrium). Hence new species can be generated with high efficiency. High yield ozone generation is the most prominent process used for many applications in water and air treatment.

DBD technology offers unpreceded possibilities of configurations to operate in different media (gas or at a liquid or solid interface) within a wide range of pressure, energy-density and temperature.

Application of DBD Technology

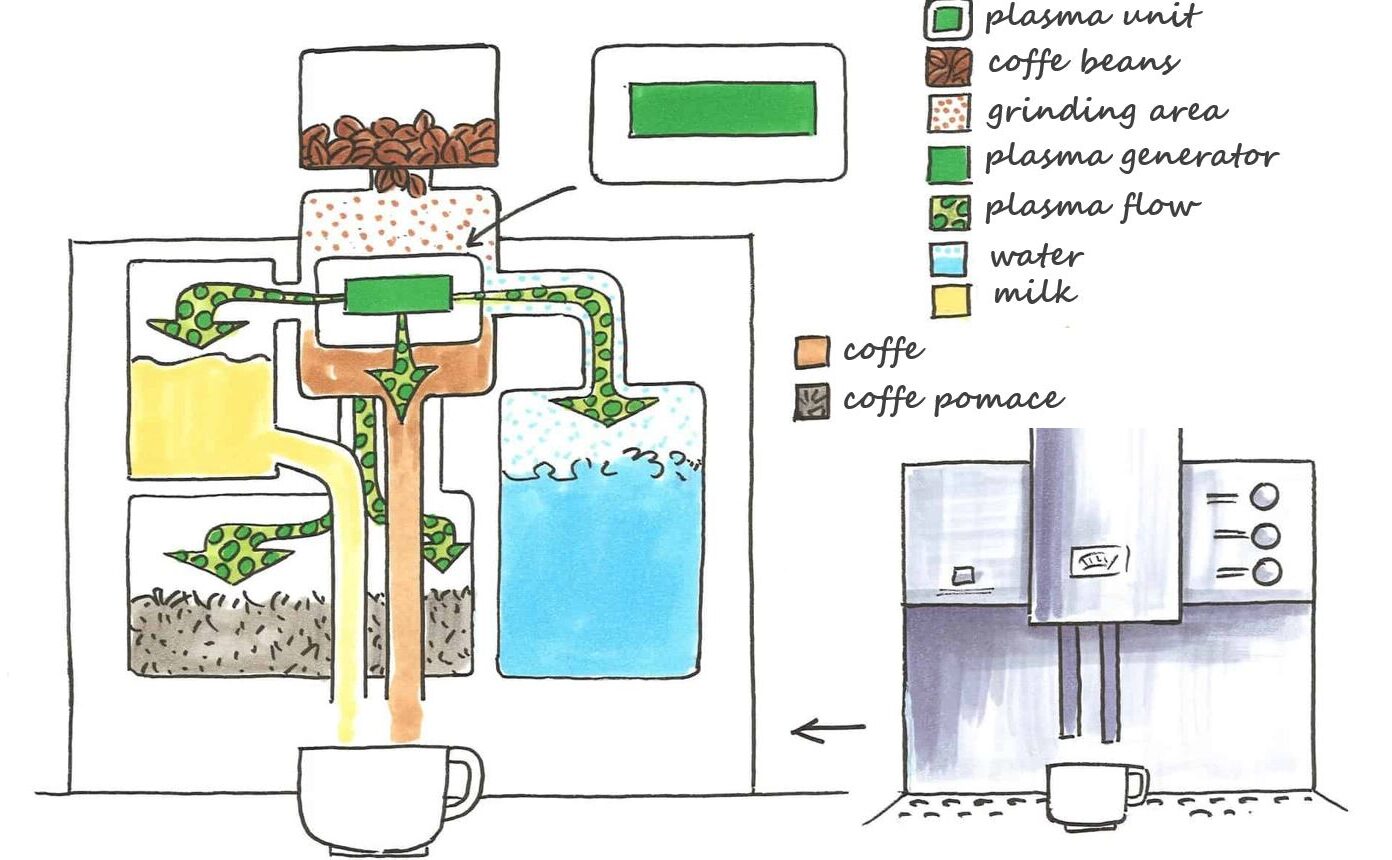

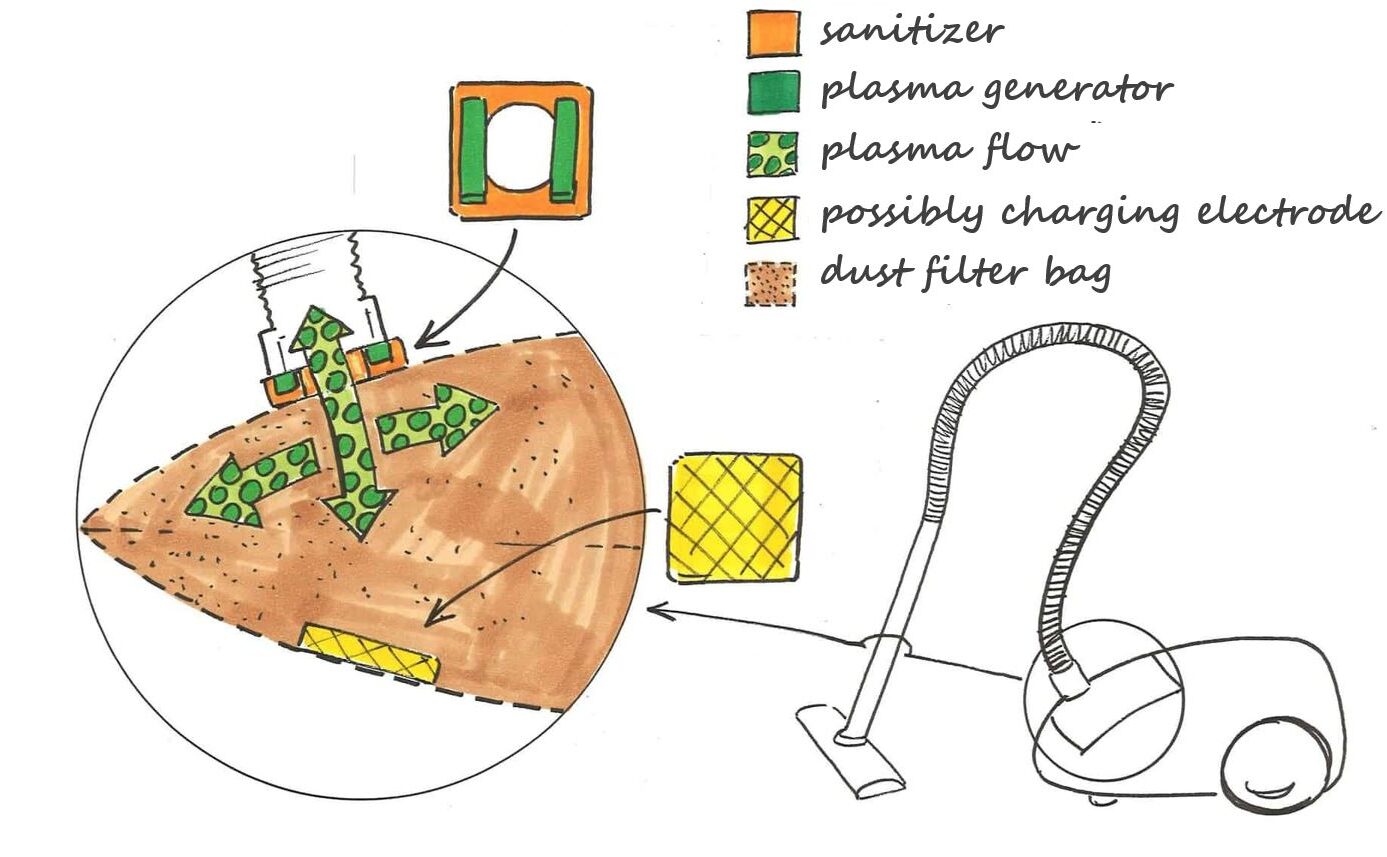

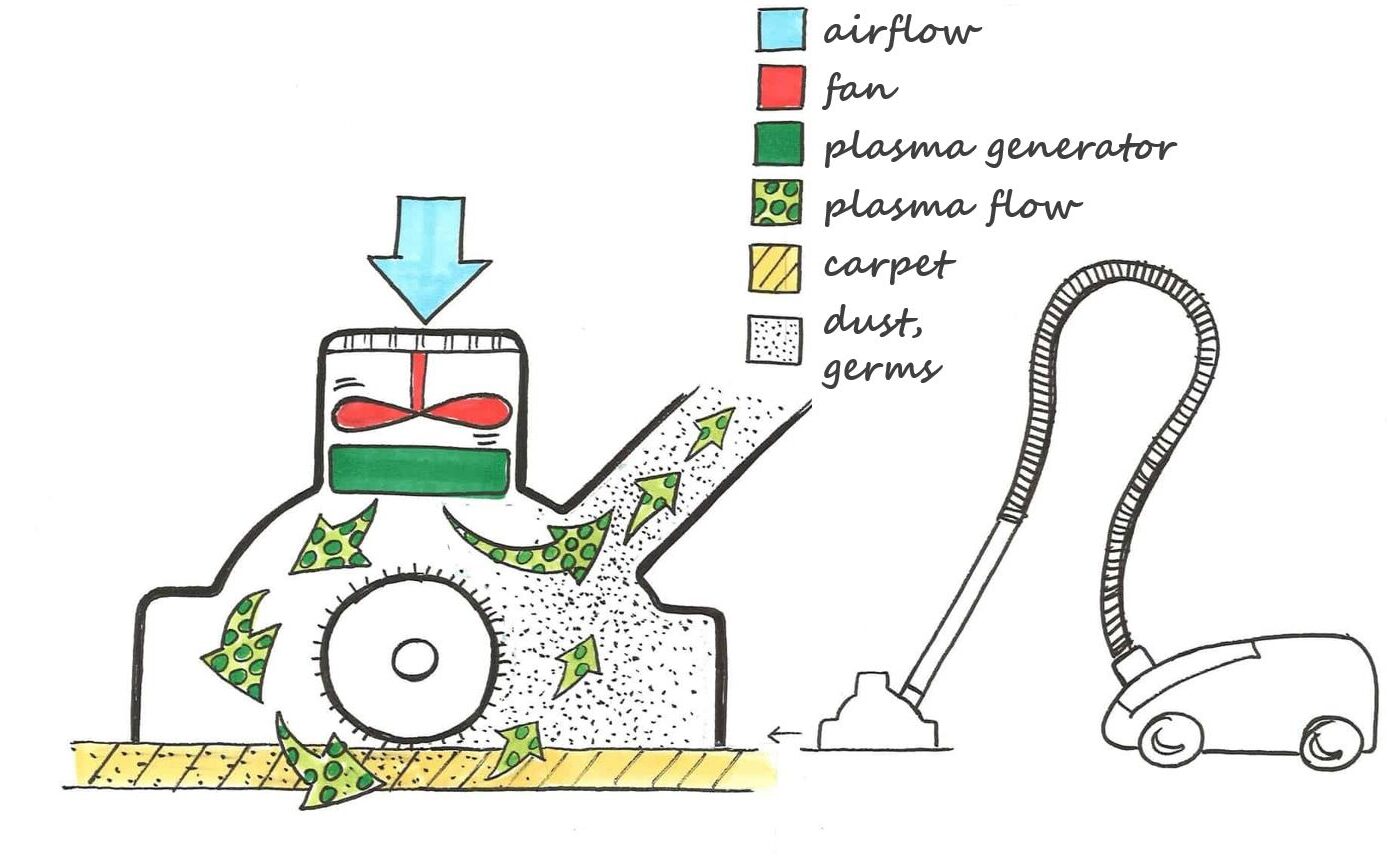

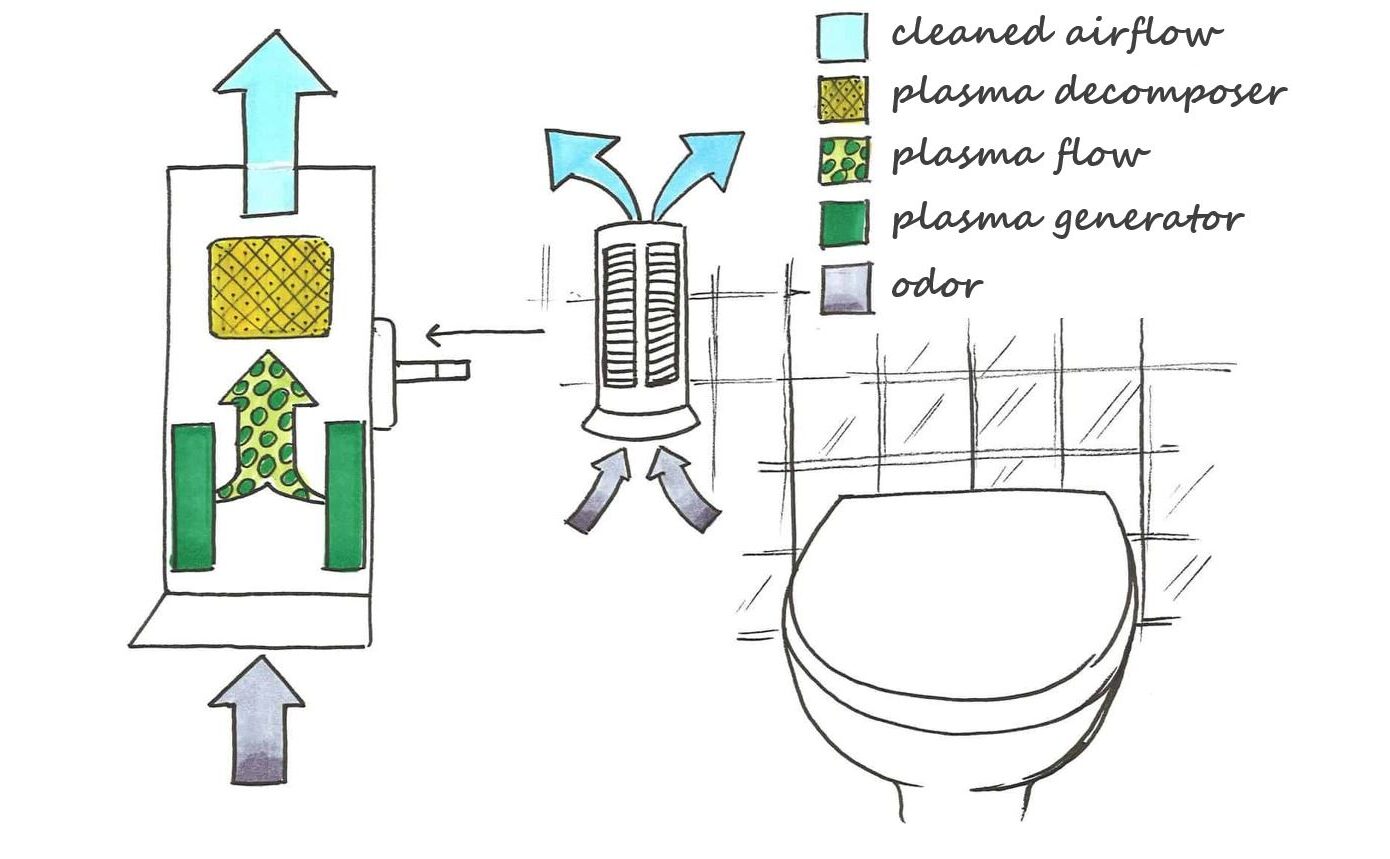

The field of application is broad. Industry, medical technology, water and air quality are just a few examples. The space-saving units are particularly suitable for integration into everyday objects such as cupboards, vacuum cleaners, ventilation systems or waste bins and offer maximum convenience for the end user.

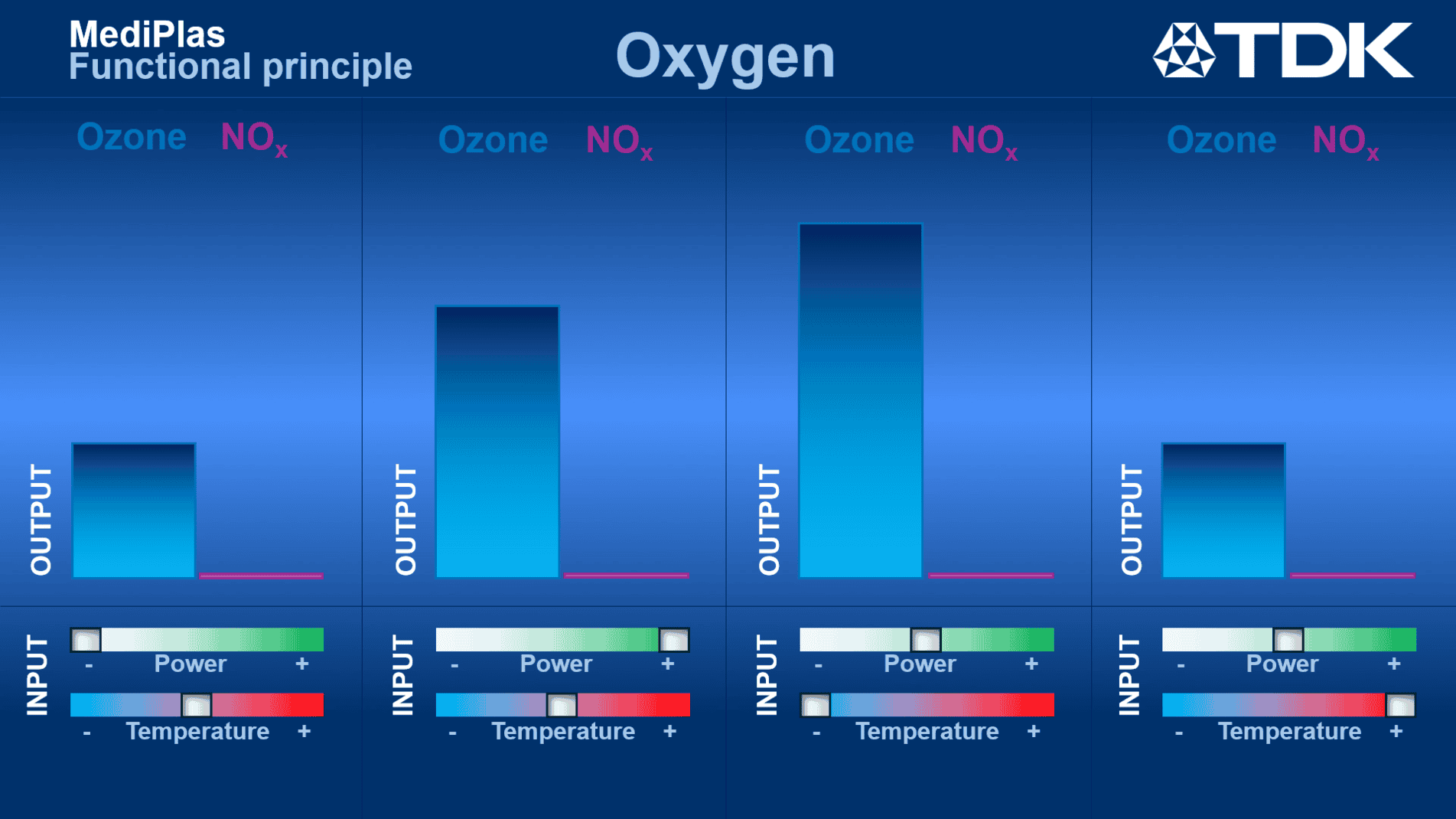

The properties of the stochastically generated microdischarges do not depend on the excitation frequency or power. They are determined by the gas properties, the pressure and the electrode configuration. Raising the power for a given configuration means generating more microdischarges per unit of time and a denser distribution of the microdischarges on the active surface. A typical atmospheric microdischarge has a 10ns duration, a filament diameter of about 100nm and up to 0.1A peak current. Local electron densities reach 1013 – 1015 cm-3 and energies up to 10eV , gas temperature remains close to ambient temperature inside the discharge gap

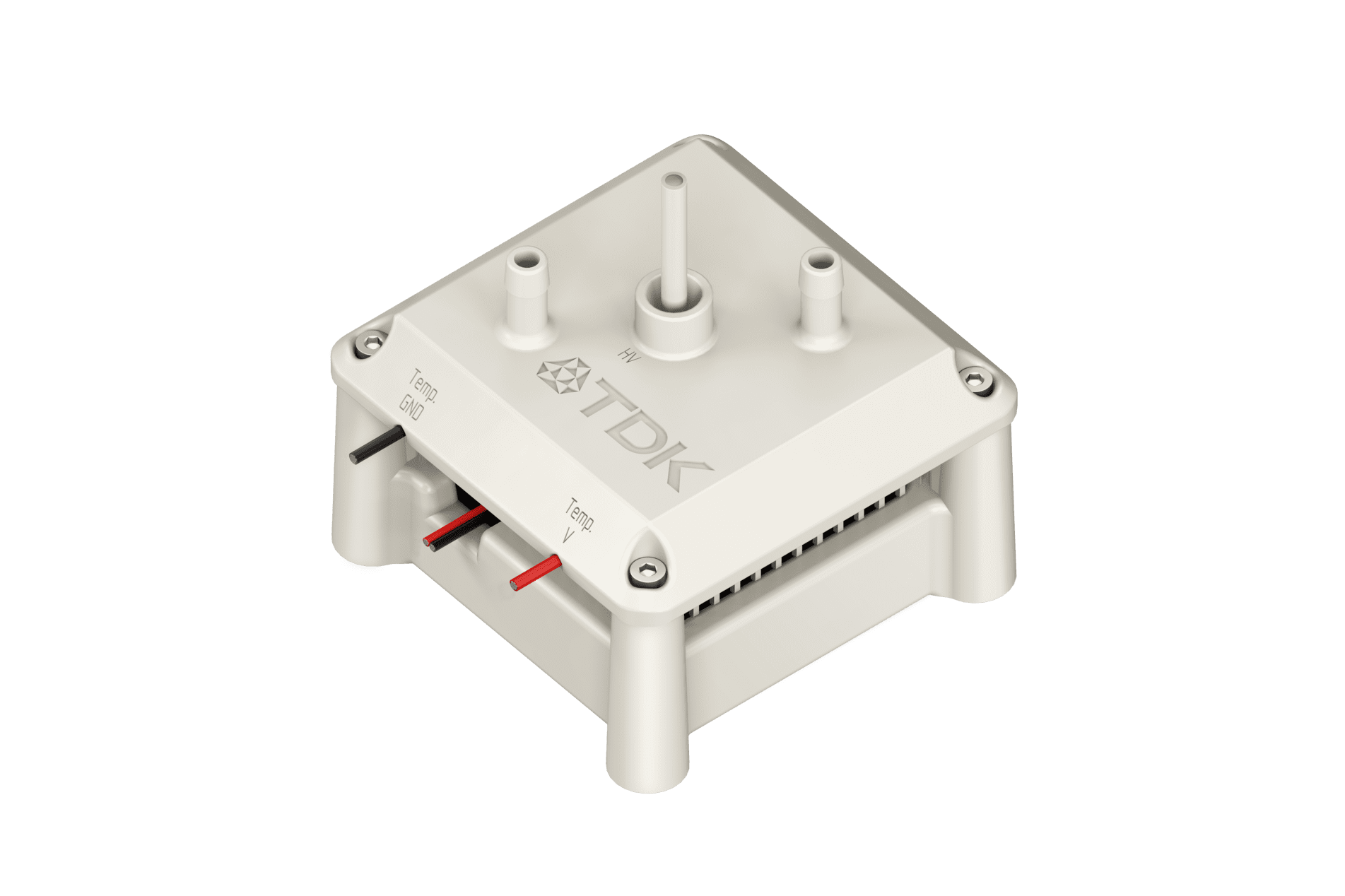

Typical DBD configurations can be designed in planar or cylindrical geometries and can be operated under forced flow, jet-like or under diffusion or convection conditions. The basic principle an be scaled over a very wide range. The voltage amplitude, frequency and power of the AC source can easily be adapted to the needs of the application.

Advantages

The advantages of the relyon plasma ionisation modules are obvious:

- Small, compact and easy to integrate

- Wide range of applications (cabinets, waste systems, lockers, etc.)

- Simple possibility to reduce odours, germs, viruses, moulds, pesticides and fungicides.

- Extremely easy handling for the end user

- Very energy-efficient due to low heat losses

- Very environmentally friendly – no auxiliary materials such as chemicals or additives necessary

- Easy to use

- Highly efficient and safe excitation of gas molecules

- Extremely high power density of the compact device

Products with DBD technology

Application examples

MediPlas ozone generator at the HZI

At the HZI, the disinfecting and sterilizing effect of plasma from the MediPlas ozone generator is being investigated in infection research.

The functional principle of the MediPlas ozone generator

The easy-to-understand information animation “Chemistry control with MediPlas” illustrates the functional principle of the MediPlas multifunctional ozone generator.

The MediPlas system based on DBD technology

The most important characteristic of dielectric barrier discharges technology is that non-equilibrium plasma conditions can be provided in a much simpler way than with other technologies.