Plasma cleaning of stainless steel sheets

SITA Messtechnik GmbH develops, produces and sells fluorescence measurement technology for the cleanliness control of parts. In the following user report Mr. Stefan Büttner and Mr. Lutz Freudenberg have investigated the efficiency and effect of plasma cleaning of stainless steel sheets by means of fluorescence measurement.

Preparation

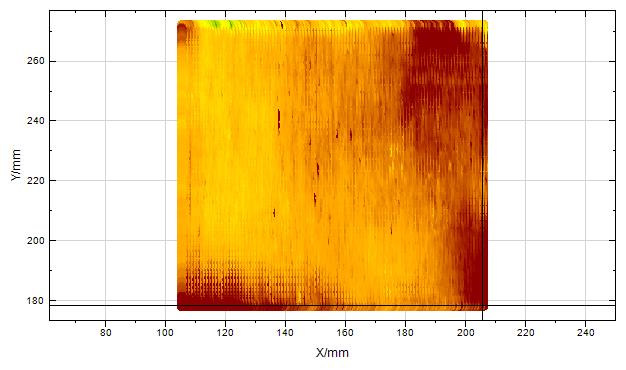

First, stainless steel plates were cleaned for 15 minutes in an ultrasonic bath at 60° C with the alkaline cleaner SurTec 151 (3 mass %) and then thoroughly rinsed with demineralized water and dried with hot air. Afterwards, a drop of Fuchs Anticorrit MRK 4 oil was applied to the clean surfaces and rubbed with a laboratory cloth.

The metal sheet was then scanned in SITA FluoScan 3D (a test bench for automated cleanliness control) using fluorescence measurement to investigate the distribution of the oil on the sheet. The fluorescence measurement is a layer thickness sensitive measurement and records the fluorescence intensity in RFU (relative fluorescence unit). The lower the measured value in RFU, the cleaner the surface.

Plasma treatment

The aim of the plasma treatment is to clean the stainless steel sheet by removing the oil film and thereby optimising the surface for subsequent processes such as bonding, varnishing or printing. For this purpose the plasma handheld device piezobrush® PZ3 is used.

This was attached to the traveling axis of the SITA FluoScan 3D so that the plasma treatment could be carried out automatically. The piezobrush® PZ3 was moved over the test plate by a programmed travel path, with the plasma switched on at a constant travel speed and at a constant distance to the surface.

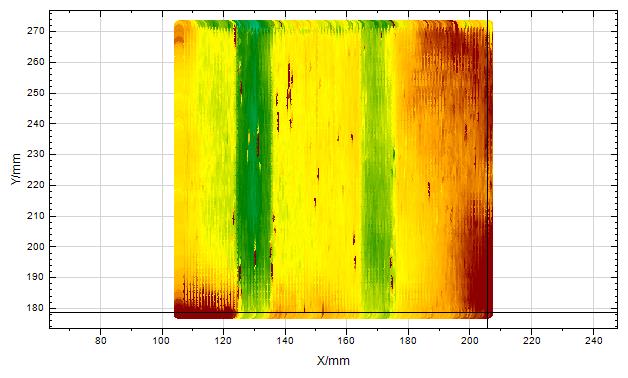

In order to make the influence of the speed clear, the treatment was first carried out at 2.5 mm/s and in the second place at half the treatment time, correspondingly at a speed of 5 mm/s. The effect of plasma cleaning was subsequently examined by a renewed fluorescence measurement on the plasma-treated metal sheets.

Summary

It can be clearly shown that the two areas that were cleaned with plasma are much cleaner than the rest of the metal sheet. It is also clear that more thorough cleaning can be achieved by a longer treatment time.

By suitable selection of the parameters of plasma cleaning with the help of fluorescence measurement to control and optimize the cleaning effect, an optimal cleaning effect can be achieved with high economic efficiency.

In the cleaning of metal parts, plasma cleaning shows its strengths especially in the field of ultra-fine cleaning and the selective cleaning of functional surfaces before cleanliness-critical processes or for high-quality products.

The effect of the plasma is clearly visible in the results of the fluorescence measurement. As expected, a longer treatment duration results in a better cleaning effect.

About SITA Messtechnik GmbH

SITA Messtechnik GmbH develops, produces and sells devices for measuring the dynamic surface tension of liquids for controlling the surfactant concentration, fully automated foam tester for analysing the foaming behaviour of liquids, fluorescence measuring technique for controlling the cleanliness of parts and for monitoring the contamination level in process liquids as well as devices for testing the wettability by measuring the contact angle. The measuring devices are robust and very easy to operate with. They are used in research, development and manufacturing laboratories of the chemical industry for analysis and quality assurance tasks and in the field of surface technology/parts cleaning for monitoring and controlling processes.